There are nowadays a dazzling array of laser machines on the market. So it takes a lot of effort to choose the best cheap laser cutter among them. As the laser technology develops, laser cutting machines are increasingly used in the metalworking and woodworking industries. More and more individuals and workshops can afford a cheap laser cutting machine.

In many cases, cheap or affordable laser cutters may mean simple structure, defective quality, low precision, and few applications. Although it’s not absolute, it is indeed necessary to do some research when purchasing an affordable CNC laser cutter.

This article provides you with 5 tips to help choose affordable laser cutters. It also recommends two of the best cheap laser cutter machines from DXTECH.

Types and price ranges of laser cutters

To buy a cheap laser engraving machine, you need to figure out the types and their price ranges. According to the laser source, the mainstream laser cutting machines fall into the fiber laser cutter and CO2 laser cutter.

Fiber laser cutting machines adopt the fiber laser generator which has a high cost. It is mainly used for cutting metal sheets, tubes and pipes. The processing materials include carbon steel, stainless steel, galvanized sheet, copper, brone, aluminum, etc. Cutting metals requires a large laser power, so the fiber laser cutter is not a very cheap laser cutter.

Even the cheapest metal cutting laser machine could cost 10 grand US dollars. The price of high-power or large-format fiber laser machines is higher, which may exceed $50,000. Therefore, they are not cheap laser cutters for home use. But for metal processing enterprises with large output and strong production capacity, the fiber laser cutter is their affordable laser cutting machine.

CO2 laser cutting machines are for cutting and engraving non-metal materials. For instance, wood, plastic, paper, leather, cloth, glass, stone, etc. The energy required to cut and engrave such materials is much less than the energy required to cut metals. So the power of the CO2 laser machine is generally much smaller than that of the cheapest metal cutting laser machine. The CO2 laser machine price is relatively low, ranging from $3,000-$10,000.

You can also find some cheap laser cutters for home use on online shopping websites. Some may cost only three or four hundred US dollars. Most of these machines are cheap laser engraving machine or cheap wood laser cutter with small power. The common features of these affordable laser cutters are small size, weak power, and few functions.

5 quick tips to choose a cheap laser cutter

Can’t wait to buy the most affordable laser cutter after understanding the types and general prices? Here are 5 tips to help you quickly understand how to choose the best affordable laser cutter.

Tip #1: Figure out your working needs.

The first step for choosing a cheap laser cutter is to make clear your own processing needs. For example, processing materials, cutting thickness, desired precision, etc. This can help you decide the type of cheap CNC laser cutter you need.

If your business is mainly cutting metal sheets and pipes, what you need is a cheap laser cutter for metals. As mentioned above, the price of fiber laser cutting machines is relatively expensive. But compared to other metal cutting tools, the advantages of fiber laser cutting machines are incomparable. Therefore, you can choose an affordable CNC laser cutter for metal within the limits of yours.

But if you need to cut sheet metals over 10 mm, a cheap laser cutting machine for metal is not your best option.

In case that your business major deals with non-metal workpieces, you can consider the cheap CO2 laser cutter or affordable laser engraving machine. A cheap desktop laser cutter or a cheap laser engraver for wood is good at cutting thin wood crafts and signs. These cheap laser cutters are quite popular with hobbyists and home users.

Tip #2: Select size, power, and other configurations.

Based on your major processing requirements, you can also determine the required machine size, power, etc.

The working size of the cheap laser cutter determines how big you can cut or engrave. A larger machine size allows you to engrave or cut larger workpieces. Even if you are making small crafts, a larger worktable can cut multiple parts at once instead of one at a time. This facilitates the mass production of small laser-cut projects. But this doesn’t mean that you have to buy the largest possible laser machine. Because the larger the size, the higher the price of the laser machine. As you can see, the cheap laser cutter for acrylic, wood, and metal are usually small in size.

The ability of a cheap laser cutter is measured in power. The greater the power, the stronger the cutting ability, and the higher the price. So, it is important to know the maximum thickness of the material you are processing. The power of the cheap laser cutting machine you buy should be just right or slightly larger to cut your thickest material. It is best to choose a cheap laser cutter with the most suitable power.

Other considerations when buying a cheap laser cutter include machining accuracy, quality, and the selection of other parts. Imported or internationally famous parts and components of the laser cutter could cost much more than domestic brands. And the laser machines with high-quality parts and components will provide better accuracy and quality. So if you want a cheap laser cutting machine, it may come at the cost of machining accuracy and quality.

Tip #3: Choose manufacturers or DIY laser cutter.

When you decide to buy an affordable CO2 laser cutter or metal cutter, you also need to decide where to buy it. The choice of brands will also have a great impact on the price of the laser machine. To buy a cheap laser cutter, consider a small brand. Because the laser machines of big names are usually expensive. Besides, both domestic brands and imported brands have affordable laser cutters.

There are many cheap Chinese laser cutters that cost several hundreds of dollars on Alibaba, eBay, and other shopping websites. Such a machine is basically a cheap laser cutter for acrylic and wood engraving. The power is only 20W, 40W, or 50W. These machines have some bad reviews. So, many people feel that the quality of cheap Chinese laser cutter is not good.

In fact, this is a kind of prejudice. Some cheap laser cutter that costs only a few hundred dollars may have poor quality and poor processing results. But there are also many Chinese brands producing laser machines with excellent quality and affordable prices. For example, DXTECH. DXTECH laser machines are exported to more than 130 countries and have been well received by many customers. This fully proves that the cheap Chinese laser cutter can also have high quality and affordable prices.

DIY a cheap laser cutter

Except for buying a complete machine, you can also buy a kit to DIY a cheap wood laser cutter. DIY laser cutter applies to the cheap desktop laser cutter with small power. Many CNC laser hobbyists treat it as the best cheap laser engraver for small items. Because DIY laser cutter can not only exercise their hands-on ability but also make their favorable laser cut projects. Keep in mind, however, that this would require a bit of technical and CNC knowledge. And also it may not dangerous due to a very high risk of creating a fire hazard.

Tip #4: Check services and support.

The service quality of each manufacturer varies greatly, as well as the warranty period. People usually pay more attention to after-sales service. For example, whether there is a daily maintenance plan, laser machine software, corresponding training systems, etc. Users are likely to find problems in the process of using a cheap laser cutter. So it is also important whether the manufacturer can provide timely solutions. Therefore, services are an key factor when choosing a cheap laser cutter.

You can try to find the answers to the following questions when buying a cheap laser cutter. If you find answers easily, it means this manufacturer can provide proper services and support. Then you can make a further inquiry for the cheap laser cutter.

Does it have technical support?

How easy is it to get a question answered?

Does it have a good company website?

Are there technicians know how to use and/or fix the affordable CO2 laser cutter?

How hard or easy to get replacement parts?

Can the best affordable laser engraver be upgraded?

Good services usually come with a higher price. The type and quality of services that the manufacturer of the cheap laser cutter provides may not be so satisfactory. This may cause you some trouble in the subsequent use process. But this is not absolute. You need to investigate the services carefully when buying the best cheap laser engraver.

Tip #5: Buy a used laser cutter.

Another great way to save money is to buy a second-hand affordable laser cutter machine. Many businesses will sell (for whatever reason) old laser machines or other big name affordable laser cutters. Many individuals or studio owners will also sell their used laser machine after they buy an upgraded one. Such a laser cutter is usually outdated and has a low configuration. But they are cheap. So if you are not chasing high precision or large production volume, the second-hand machine can be a choice of buying a cheap laser cutter.

There are certain risks in buying a used affordable laser engraving machine. Many parts and components may have worn out because such a cheap laser cutter has been used for a period of time. You may need to replace the parts after buying and using for a period. Or the processing accuracy is not good enough to meet your requirements. Therefore, you have to be careful when buying a second-hand cheap laser cutter.

Cheap laser cutter recommendation

Affordable and Cheapest Metal Laser Cutting Machine

This is an economical fiber laser cutting machine for various metal materials. Its flatbed structure is suitable for cutting metal sheets. For instance, stainless steel, carbon steel, galvanized sheet, aluminum, copper, bronze sheets, etc. Features of this metal laser cutting machine include high efficiency, excellent precision, low energy consumption, and simple maintenance. The power options of this laser machine range from 1000W to 8000W.

The general price of this machine ranges from $10,000 to $25,000, based on different specifications and configurations. It is never a cheap laser cutter for individuals or hobbyists. But for a medium or large-scale metalworking factory or workshop, this could be the best affordable laser cutter. Because it can bring many unparalleled advantages compared with traditional metal cutting tools.

For example, it adopts a pipe-weld machine frame that is rigid and durable and not likely to deform. Many of its key parts and components adopt imported brands, ensuring safe and reliable long-term operation. Even with a large amount of initial investment, it can bring considerable incoming in the future use.

The Best Affordable Laser Engraver and Cutter for Sale

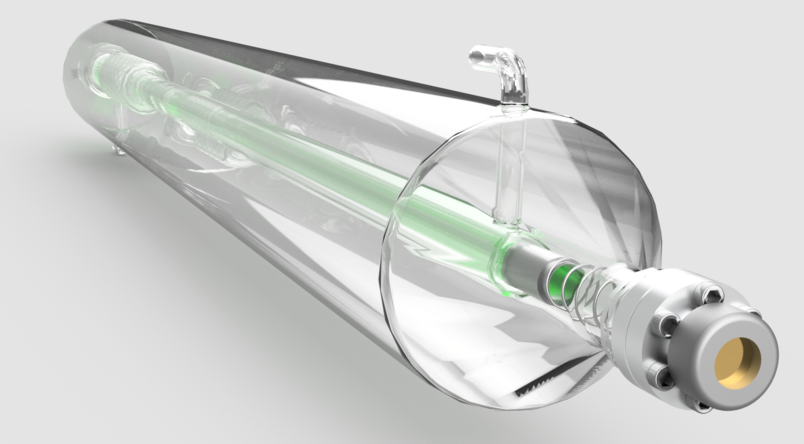

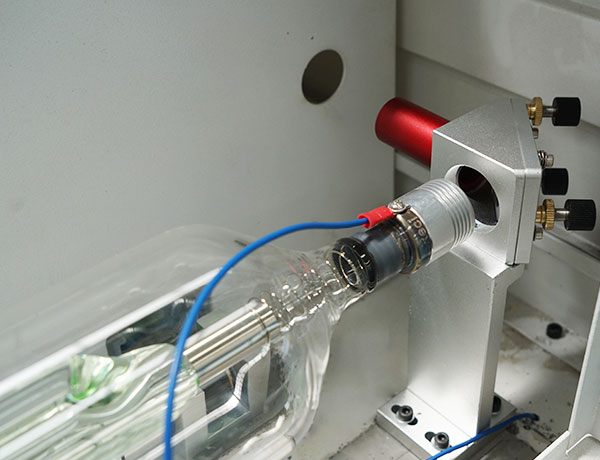

This is a cheap laser engraver for wood, acrylic, fabric, paper, glass, leather, and other non-metal materials. Besides engraving, it can also cut and etch these materials. It is a cheap CO2 laser cutter. The power options can be 80W, 100W, 130W, 150W, etc. Different powers have different cutting depths. You shall choose the laser cutter with the most suitable power according to your specific needs.

The price of this cheap laser cutter is about $3000 to $5000. The effective working area is 1300*900mm. It is good at cutting all kinds of small and medium-sized wood crafts and signs. Due to its compact size, it is an affordable laser cutting machine for hobbyists to use at home.

It is equipped with a protective cover. The laser could harm people’s eyes if people stare at the cutting process for a long time. Besides, when cutting some materials, such as certain plastic, it will emit toxic smoke. The protective cover now plays an important role in protecting both the operator’s safety and the environment.

Advice for choosing a cheap laser cutter

It is human nature to buy cheap things. This is also true when choosing a laser cutting machine. People tend to buy the most affordable laser cutting machine that also best meets their needs. But you can’t blindly pursue cheap prices. There are also some other considerations when choosing a cheap CNC laser cutter. A cheap laser cutter does not necessarily mean poor quality. And an expensive machine does not necessarily mean good quality and services.

Here are several suggestions when buying a cheap laser cutter:

- For workshops or factories with mass production needs, I suggest buying the most affordable laser cutter with the largest size. Of course, this shall be based on your specific processing needs. Because a large size allows to make larger designs or cut and engrave multiple workpieces at the same time. It doesn’t need to frequently start and stop the laser machine to replace materials.

- The power reflects the cutting ability of a laser cutter. I suggest buying a cheap laser cutting machine with the power slightly larger than what you need. So even though you need to cut thicker materials in the future, you don’t need to upgrade to a larger power. However, in case of limited budget, you can start from a weaker power. And upgrade to a more powerful laser later when you have enough money.

- For CNC machinery enthusiasts or people who have plenty of time, DIY laser cutter is a good choice. The enthusiasts will get much sense of accomplishment and satisfaction when assembling and running such a cheap desktop laser cutter. DIY the best affordable laser engraver requires a certain degree of mechanical knowledge and hands-on ability.

Conclusion

The cheap laser cutter is not a consumer product. It is a tool to help you bring revenues, improve production efficiency, increase production capacity, and reduce production costs. This article provides 5 tips to help you quickly understand how to buy a cheap laser cutter. Knowing your processing needs can help you understand the laser cutter type you need. You may also decide the power, size and other configurations based on your needs. DIY a laser cutter or buying a used one helps you save some money too. Remember to select a proper manufacturer and check its services and supports when buying a cheap laser cutter.

DXTECH also has many cheap laser cutting machines that handle metal or non-metal materials. DXTECH affordable laser cutters have excellent quality, perfect after-sales service, and high cost performance. If you are interested in DXTECH cheap laser cutters, feel free to get in touch.