Laser Cutting Machine Applications

Laser cutting machine uses the interaction between laser beams and materials to cut, weld, engrave and mark on metal and non-metal materials. Relying on the advantages of extremely high cutting speed, high stability, extremely low use cost, high photoelectric conversion rate and relatively simple operation, the laser cutter is widely used in vast industries.

Laser Cutting Materials

With different types of forcefully penetrable laser beam, laser cutting machine nearly can cut all kinds of materials. The main types of the material, can be divided into two general categories: laser cutting metal material, and non-metal material.

Laser Cutting Metal Materials:

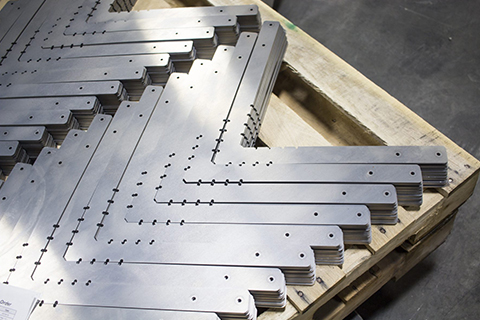

There is laser metal cutting machine to deal with various metal materials like aluminum, brass, copper, titanium, stainless steel, etc. The powerful laser beam cuts metal materials through and creates a high-finished, smooth cutting edge result, not only for metal sheet cutting but also for cutting delicate metal parts. The precise cutting process allows the laser metal cutting machine achieves mini metal part production massively that reduce lots of labor cost and improve production efficiency.

Laser Cutting Non-Metal Materials:

Other laser cutting materials are not related with metal. People use this cutting machine to deal with somethings like plastic, wood, fabric, leather, etc. This application may not require powerful laser beam like laser metal cutting machine has, but it needs more cautions and specialized laser cutting technology to make perfect cutting result upon those materials.

Acrylic includes different types, like ABS, Polyester, Polystyrene, etc. With the various types and vast usage, acrylic now has become one of the commonest non-metal materials in manufacturing. Smooth, elegant cutting edge created by laser cut acrylic has become the reason for most acrylic cutting manufacturers to select laser cutting acrylic.

Don’t be worry about the burnt cutting edge, because the cutting machine for wood takes advanced and specialized non-metal cutting technology that distinguishes from the metal cutting, the powerful one. You will have satisfied cutting result with wood laser cutting machine.

Laser Cutting Other Materials:

- Laser cut fabric

- Laser cut leather

Laser Cutting Products

As laser cutting technology widely applying, different cutting products can be produced by this kind of cutting machine. From delicate crafts to enormous industrial components, the cutting machine creates glorious decorations and complex industrial parts.

Laser Cutting Industries

With high cutting speed, stability, extremely low use cost, well photoelectric conversion rate and relatively simple operation, laser cutting machine has become the first choice for most manufacturers to create various accessories at amount of industries.

Comparing to the mechanical processing, laser cutting machine has many advantages. It has wide processing objects, small deformation, great accuracy, energy saving, high degree of automation, high production efficiency, without tool wear. Because of these advantages, laser cutting machine has widely used in various industries and become popular in recent years.

Taking professional laser manufacturers as an example, let’s take a look at the application industries of laser machines:

Kitchenware Industry

Laser cutting machine has the advantages of fast speed, high precision, high production efficiency, and can realize the development of customized kitchenware.

Automotive Industry

The use of laser cutting technology not only enables rapid batch processing, high accuracy, high efficiency, no burrs, and one-shot molding.

Fitness equipment industry

The diversity of fitness equipment also places higher requirements on processing methods.

Advertising Industry

High-precision laser cutting technology eliminates the need for secondary rework, which greatly improves work efficiency and saves corporate costs.

Sheet metal processing industry

Traditional sheet metal cutting equipment can no longer meet the current process and cutting form requirements.

Shipbuilding industry

No secondary processing is required, and welding can be performed directly. Therefore, the number of man-hours can be reduced