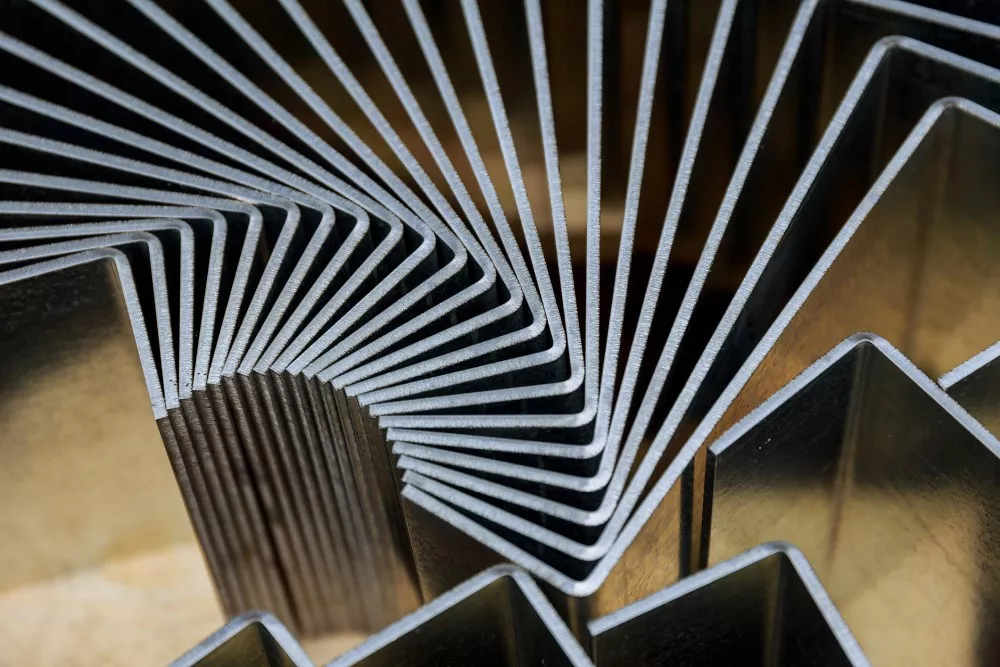

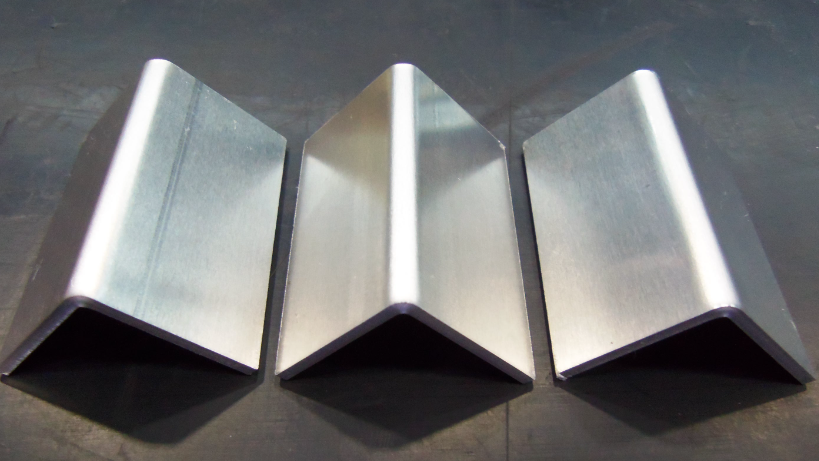

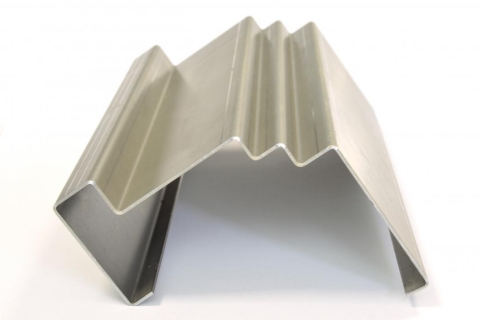

Sheet Metal Bending Samples

Bending machines can bend a variety of metal materials such as stainless steel, iron, copper, aluminum, titanium and carbon steel. As small as non-ferrous metals, ferrous metal sheets, automobiles and ships, electrical appliances, decoration, kitchen utensils, cabinets, elevator cabinet doors, cutting and bending processing; as large as the aerospace field, CNC shearing machines and CNC bending machines are playing an increasingly important role.

We provide free proofing, welcome to consult.

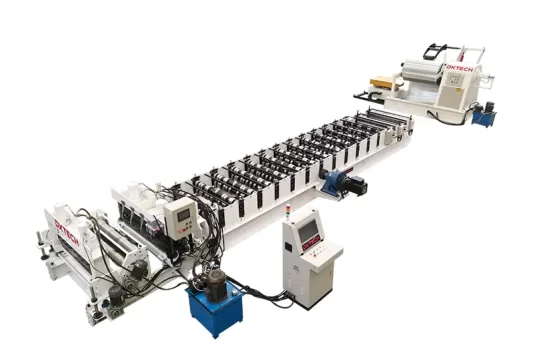

1.The main features of the machine

Hydraulic press brake adopts steel plate welding structure; vibration aging eliminates stress, the frame is machined with good rigidity and stability; it works smoothly, is safe and reliable, and is easy to operate; through electrical Coordinated control with hydraulic system to achieve ideal bending effect.

2.The main components and structure of the machine

2.1. Slider part: The hydraulic press brake slider part is composed of a slider, an oil cylinder and a automatically stopper fine-tuning structure. The left and right oil cylinders are fixed on the frame, and the piston (rod) drives the slider to move up and down through hydraulic pressure.

2.2. The working table is composed of a movable working table and a vertical plate, which is processed by a large CNC milling and boring machine.

2.3. Synchronization system: This machine consists of a automatically synchronization composed of a torsion shaft and an arm, with simple structure, stable and reliable performance, and high synchronization accuracy. The automatically stop is adjusted by the motor, and the ESA system displays the value.

2.4. Stopper automation

2.5. Outsourcing accessories

2.5.1. Main electrical components: Suzhou Siemens Electric Co., Ltd.;

2.5.2. Hydraulic parts: Rexroth;

2.5.3. Sealing ring: Japan Valqua Company;

2.5.4. Control system: ESA S640

2.5.5. Main motor: Jiangsu Yingkai Motor Company.

2.5.6. Oil pump: Sunny USA

2.5.7. Mould material: T10# steel whole body heat treatment, quenching and tempering.

3.Main technical parameters

| Model | 80T/2500 | 100T/3200 | 125T/3200mm |

| CNC System | CybTouch 8 PS | CybTouch 8 PS | CybTouch 8 PS |

| Nominal Force | 3+1(Y1、Y2、X +V) | 3+1(Y1、Y2、X +V) | 4+1(Y1、Y2、X、R +V) |

| Number Of Control Axes | ±0.01mm | ±0.01mm | ±0.01mm |

| Table Length | 800kN | 1000kN | 1250kN |

| Distance Between Columns | 2500mm | 3200mm | 3200mm |

| Throat Depth | 1960mm | 2700mm | 2700mm |

| Slider Stroke | 360mm | 400mm | 400mm |

| Opening Height | 200mm | 200mm | 200mm |

| Oil Pump | 460mm | 450mm | 450mm |

| Control Accuracy | 7.5 KW | 7.5KW | 7.5KW |

| Main Motor Power | 16F | 16F | 16F |

| Electrical Components | Schneider | Schneider | Schneider |

| Ball Screw | TBI | TBI | TBI |

| Back Gauge Guide Rail | HIWIN | HIWIN | HIWIN |

4.Working environment and conditions of use

This machine is suitable for any material preparation workshop, and its conditions are:

- Ambient temperature: -10~+40℃ (the temperature of the fuel tank shall not be lower than +10℃)

- Relative humidity: ≤80% (+25℃)

- Power source: 3phase 380V±10% 50Hz(or customized)

This machine has no “three wastes” discharged, and the noise limit meets the requirements of JB9969-1999.

5.Installation, test, acceptance and after service

5.1.Seller should inform the buyer to inspect the machine in our factory after the machine is finished.

5.2.Seller should supply corresponding files and foundation drawings in 7 days after confirming the order.

5.3.If buyer needs the installation, test by seller, then the charges in China will be taken by seller. And charges out of China, such as tickets, and hotels, should be taken by the buyer.

Reviews

There are no reviews yet.