Do you want a metal and wood laser cutting machine that can personalize your business and add personality to your gifts? Why not invest in a metal and wood laser cutting machine? Now that the laser cutting technology has peaked having the best metal and wood laser cutting machine may not cost as much as you expect. The metal and wood laser cutting machine used to be something that only large companies could afford. But nowadays, there are more metal and wood laser cutting machine choices that individuals can afford. You can buy entry-level metal and wood laser cutting machines at DXTECH.

Add DXTECH’s metal and wood laser cutting machine to your toolbox

The metal and wood laser cutting machine is a hybrid cutting machine, which can be used to cut metal and wood. DXTECH provides intelligent metal and wood laser cutting machines, engraving machines, and marker solutions. Our metal and wood laser cutting machine can cut and process toys, arts, crafts, souvenirs, gifts, architectural models, and inserts. When using metal and wood laser cutting machines to process artwork, the emphasis is often on personalized customization options.

DXTECH’s metal and wood laser cutting machine can process all kinds of wood and metal into your favorite shape and cut and process up to 20 mm in thickness. Our metal and wood laser cutting machine is easy to operate, strong and durable, and is the ideal choice for your cutting business. Use DXTECH’s metal and wood laser cutting machine to present your artistic design instantly.

What kind of wood can be processed by DXTECH’s metal and wood laser cutting machine?

Multi-layer timber

Medium Density Fiberboard

Plywood

Particleboard

Flake

Solid wood

Maple

pine

Acacia

Cherry wood

Light raft

cork

Bamboo

Synthetic resin

Birch

Laminate

Beech

Basswood

Mahogany

Oaktree

Walnut tree

Ash tree

Poplar

Eucalyptus

cedar

Spruce

Teak

What metals can be processed by DXTECH’s metal and wood laser cutting machine?

Carbon steel

stainless steel

Aluminum and alloys

Copper and alloys

Titanium and alloys

alloy steel

Nickel alloy

What are the advantages of DXTECH’s metal and wood laser cutting machine

1. High precision

Our metal and wood laser cutting machine has a narrow cut and smoother cut surface. No rounded corners and burrs (shortcomings of traditional cutting) are often found in the mechanical feed opening, and the cutting deformation is small.

2. High speed

The power of the fiber optic device affects the cutting speed, and increasing the power of the fiber optic device will also increase the cutting speed.

3. Efficient

DXTECH’s metal and wood laser cutting machine is non-contact processing (advantages), without the impact of mechanical punching (disadvantages of traditional cutting). Therefore, there will be no wear of the cutting tool. Cut into shape once; no need for follow-up processing.

4. Good flexibility

No need for knives and abrasive tools. Combined with CAD technology, we can use our metal and wood laser cutting machine to cut plates of any shape and size. Especially suitable for cutting complex parts.

5. Easy to use

Cutting can be realized by importing graphics setting parameters into the computer, and it is easy to learn.

6. Low maintenance cost

There is almost no maintenance cost for later use; only the cooling water needs to be replaced regularly.

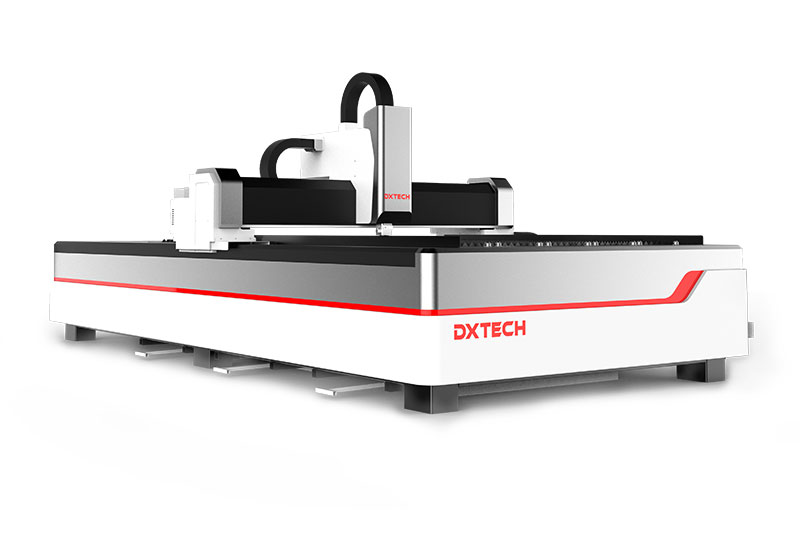

Here are some of the best metal and wood laser cutting machines from DXTECH

Metal and wood laser cutting machine with protective cover

This is a metal and wood laser cutting machine with a protective cover. It has a compact appearance and a small footprint, so it is more convenient to use. In addition, this metal and wood laser cutting machine is equipped with a protective cover, which makes the operation safer and more environmentally friendly. It is more suitable for users who have higher requirements for environmental protection. And its integration level is very high, operation and maintenance are more convenient.

Therefore, the service life of this metal and wood laser cutting machine can be extended to a certain extent. With a high-quality motion control system and the most easy-to-use functions, this metal and wood laser cutting machine can meet your entrepreneurial and startup goals.

Advantage

- The laser tube power of this metal and wood laser cutting machine ranges from 40w to 150w. It can cut materials of different thicknesses.

- An automatic focusing device is added, which can be calibrated through the software machine and find the focus to be cut.

- The user can select two types of table tops for this metal and wood laser cutting machine at the same time and replace the tabletops with different materials to obtain better results.

Desktop metal and wood laser cutting machine

This is a desktop metal and wood laser cutting machine. The metal and wood laser cutting machine has been upgraded to make it more suitable for processing non-metallic materials in appearance and function. The particular metal and wood laser cutting machine design brings more convenience and saves more space for users. The desktop metal and wood laser cutting machine adopts an integrated frame structure design, making the device more stable during operation.

According to different processing objects, you can upgrade this metal and wood laser cutting machine and equip it with varying accessories of processing to meet the diverse processing needs of users. For example, you can choose a blade table or a honeycomb table according to the nature of the processing material. You can install a soft material adsorption device to fix the workpiece. Flexible equipment meets individual processing requirements.

Advantage

- The use of internal sliding guides has advantages, namely low friction, and low running resistance.

- Effectively improve the processing efficiency.

- Using DSP control technology, continuous, high-speed curve cutting and short-distance processing optimization functions can be realized.

- The beam compensation can be performed automatically during the cutting process, which significantly improves the processing quality.

Hybrid metal and wood laser cutting machine

This is a metal and wood laser cutting machine with a mixed cutting function. It can meet the cutting of acrylic, plastic, rubber, and other non-metallic materials and cut thinner stainless steel, carbon steel, and other metal plates. If your processing needs include metal and non-metal materials, this metal and wood laser cutting machine is definitely your best choice. Compared with other metal and wood laser cutting machines, this machine has a more extensive processing range.

This metal and wood laser cutting machine can cut acrylic, leather, rubber, and other non-metallic materials and realize the metal material stainless steel and carbon steel that you want about 1.2mm. For customers who want to cut metal and non-metal materials, this is the most affordable metal and wood laser cutting machine. This kind of metal and wood laser cutting machine is widely used in the advertising industry, handicraft production, decoration, rubber sheet furniture, and other industries.

Advantage

- The hybrid cutting laser head can realize the processing of non-metallic materials and some metal materials.

- The laser head has an automatic focus function, which ensures the processing quality and eliminates the need for secondary processing of the workpiece.

- Imported parts such as Taiwan guide rails, lead screws, etc., to ensure a long service life of the machine.

- The laser tube has the advantages of long service life and low maintenance cost.

Economical metal and wood laser cutting machine

This is an economical metal and wood laser cutting machine. It has the characteristics of high cost performance, low cost, simple maintenance, and convenient operation. This metal and wood laser cutting machine can process most metal materials, such as stainless steel and carbon steel. This economical metal and wood laser cutting machine has the advantages of high cost performance, low consumption, and low cost.

Simple maintenance and convenient operation. The metal and wood laser cutting machine can cut and process various metal materials, such as stainless steel, carbon steel, and galvanized sheets. Therefore, this economic fiber laser cutting machine is becoming more and more popular at home and abroad. This type of metal and wood laser cutting machine can process most metal materials, such as stainless steel, carbon steel, and galvanized sheets. Sheet metal processing, lighting, kitchenware, decorative materials, cabinets, and other industries generally use this metal and wood laser cutting machine.

Advantage

- The cutting speed is fast, the efficiency is high, the operation is safe, and the performance is stable.

- The spot quality is good, the deformation is small, and the appearance is smooth and beautiful.

- Imported servo motor and oriented transmission mechanism are adopted, and the cutting precision is high.

- Professional software designs various graphics or text, which can be processed immediately, with flexible processing and simple and convenient operation.

Multifunctional metal and wood laser cutting machine

This dual-purpose metal and wood laser cutting machine can process metal plates and metal tubes very efficiently. It combines a metal plate processing platform and a metal tube cutting machine, saving a lot of initial investment and working space. Many customers at home and abroad have widely recognized this dual-purpose metal and wood laser cutting machine. If you need to process metal plates and metal tubes simultaneously, this dual-purpose metal and wood laser cutting machine is the best cost-effective choice.

This metal and wood laser cutting machine is the best choice for processing complex metal parts. It can not only process metal plates quickly and accurately but also perform the precise cutting. DXTECH equips it with world-class components, such as Raycus/Max laser source, Japanese Yaskawa/Fuji servo motor, Taiwan HIWIN/PMI guide rail, French Schneider electronic parts, etc. It can be customized according to customer needs. It is widely used in auto parts, robot parts, rocket parts, aircraft parts, ship parts, household appliances parts, metal tools, construction machinery parts, agricultural machinery parts, metal decoration, metal furniture, kitchen countertops, kitchenware, fitness equipment, and other industries. metal and wood laser cutting machine

Advantage

- With the help of a metal plate processing platform and a metal tube cutting machine, the metal and wood laser cutting machine

- It can handle metal plates and tubes and save on the purchase cost for users.

- Adopt a high-quality Raycus/Max laser source and world-class laser cutting head. The metal and wood laser cutting machine can release high-quality laser beams and accurately cut metal.

- Equipped with heavy cast iron bed. The metal and wood laser cutting machine runs stably and will not deform within 20 years.

- Manufactured with an aviation aluminum beam, the cutting speed is very fast, and the machining accuracy can be guaranteed at the same time.

Will it burn when using metal and wood laser cutting machines to process wood materials?

Yes, the process of metal and wood laser cutting machine processing wood materials is a sublimation effect. However, this effect is not harmful and, in many cases, is exactly what we need. Just focus accurately, select the appropriate laser processing parameters and optical lenses, and appropriately apply compressed air to obtain the best laser cutting results for wooden materials.

How to achieve a deep black laser cutting effect?

With a defocus of 0.5-2 mm, the laser spot diameter of the metal and wood laser cutting machine will become larger. Colleagues, the energy density of the laser will decrease. Therefore, a dark laser cutting effect can be achieved. But at the same time, the details of the graphics may not be visible.

The limitations about he metal and wood laser cutting machine

Although the metal and wood laser cutting machine has been widely used, there is still much room for improvement. For the application of metal and wood laser cutting machine, the current limitations are:

Difficult to control

The cutting methods of metal and wood laser cutting machines include burning cutting, melting cutting, and sublimation cutting, but only burning and sublimation cutting can be achieved on wood. If it uses combustion cutting, it is necessary to add a cooling and flame extinguishing process immediately after the metal. The wood laser cutting machine is irradiated, which makes the equipment more complicated. The control of the metal and wood laser cutting machine machining process is also a problem. If sublimation cutting is used, ultra-fast laser, high-power, and instantaneous processing must be used. In this way, it can be ensured that while the material in the slit is sublimated, the material near the slit will not be ignited.

Small processing thickness

Since the metal and wood laser cutting machine needs to be focused, the laser beam concentration distance is very short after focusing, which means that the thickness that can be processed is small. In woodworking, there are often large-thickness sections, which are more limited.

Expensive

Generally, metal and wood laser cutting machines are expensive, and the unit price of the ultra-fast laser above is more than one million RMB.