Application of Laser Machine in ADVERTISING Industry

Advertising has always been the perfect stage for laser technology to display its special characteristics. Here, laser technologies can communicate diverse desires in a range of forms, such as light and dark, voice music and movement that people want to see. The magic effect reveals the features of the metal cutter machine. It’s incisive. The application of signs and advertising is one of the key areas in which laser processing equipment is commonly used. The promotion and implementation of laser cutter engraver and metal cutter machine has brought fresh momentum to the advertisement industry and has moved the production of signage and signage to a different application.

The advertisement industry is developing steadily and is in the golden era of growth. Society is continually changing, and there are more standards for the advertisement business. The use of CNC metal cutting in the advertisement field is very important. Metal cutter machine refers to the different sectors and materials regulated by the advertising industry, which have significantly encouraged the growth and reform of the advertising industry.

Applicable Advantages for Advertising Industry

- Material Saving: Our metal cutter machine upload sketches to computers which can automatically configure the structure to improve material usage.

- High Precision and Efficiency: Our metal cutter machine offer high cutting accuracy, the goods need only one time cutting, the cutting edge is smooth and no post-processing is needed.

- Cost savings: In CNC metal cutting, no mold is required, saving a lot of the cost of producing and fixing molds.

- Eco-friendly: No noise and no emissions, laser cutting would not break environmental laws. Metal cutter machine dramatically reduces scrap cutting and leaves the workspace tidy.

Laser Cutting Advertising Supplies

CNC metal cutting in the advertisement industry According to incomplete figures, the present penetration rate of laser processing equipment in the industry is still less than 5%. CNC metal cutting machine in the advertisement industry with the growth of the industry, the need to update the original tool processing equipment to the laser cutting machine would increase. In the future, the application industry will create consumer demand for more than 50,000 laser cutting machines.

Achieving 1.1 billion Yuan, about 28 times the scale of the existing market.

For the statistics on such data, it can be understood that the use of CNC metal cutting machine is very widespread, not only occupying a leading role in the advertisement sector, but also occupying an important position on both sides of industry.

In the advertisement industry, nature itself is the reason why it is so common, the commodity has less consumables, and the use of the environment is safe and hygienic and is ideal for environmental conservation. The key thing for ads is to be able to cut different items according to the needs of the consumer, as long as the machine can monitor the sketches and automatically cut good samples, which increases the versatility of the business. The growth of the advertisement industry is to design the products that consumers need according to consumer needs, making the laser cutter engraver the most effective instrument for the rapid development of the advertising industry.

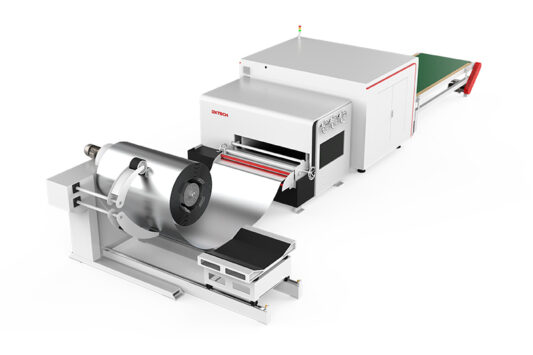

Product Display

Sheet metal cutting for sign boards

Driving out, road signs and signs are the best instruments to guide the road. But there’s a billboard that looks like a street sign, but it’s really a billboard. Advertising signs typically involve a thin metal material, and the laser may be used to cut thin metal sheets rapidly and precisely.

Advertising light box metal sheet metal cutting

The promotional light box incorporates the benefits of neon light, which can easily boost people’s visual impact and provide a positive marketing effect. The Laser cutter engraver system is ideal for the manufacturing of different thin metal materials such as iron, stainless steel, and titanium gold and copper. After Laser cutter engraver and cutting, the metal plate of the advertisement light box can be painted and welded directly without secondary processing.

Advertising using metals sheets

The promotional metal show stand combined with the innovative company LOGO will enhance the promotion of the product. Using Laser cutter engraver to cut a variety of metal display frame thin metal layer, with late electrostatic spraying, baking procedure, to produce exquisite, robust and durable product results.

Laser Cutting Process

The cutting of screens, signs and inscriptions using CO2 laser systems is distinguished by a high degree of accuracy and versatility. Many materials may be sliced, such as acrylic, plastic foils, textiles or wooden materials. Like lasers, euro laser cutters may also be fitted with mechanical tools (milling machine, knife) this versatility is especially needed in advertisement technology.