Video

Features:

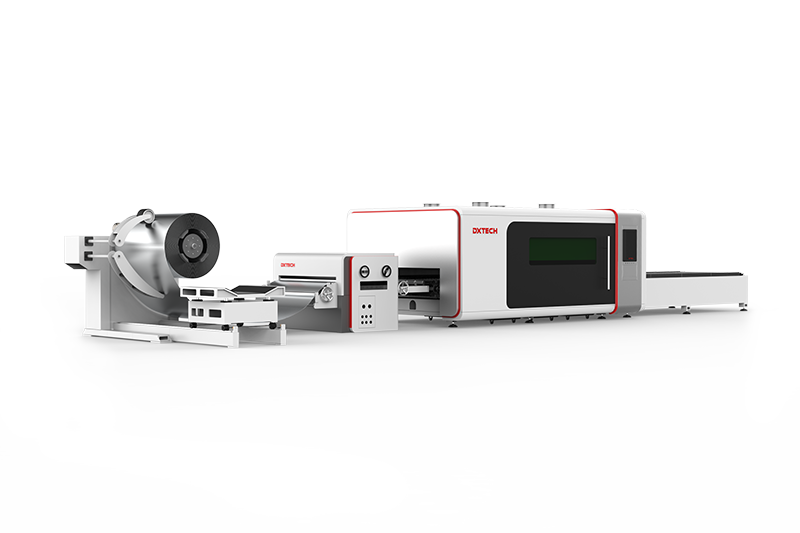

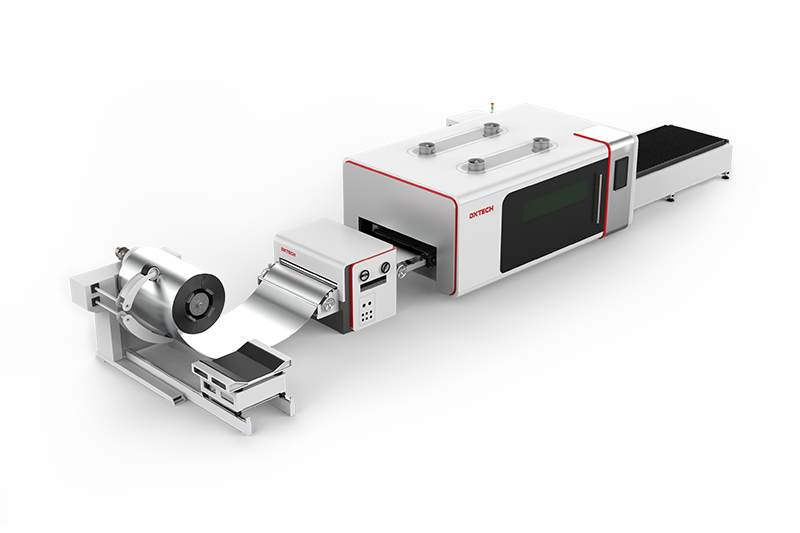

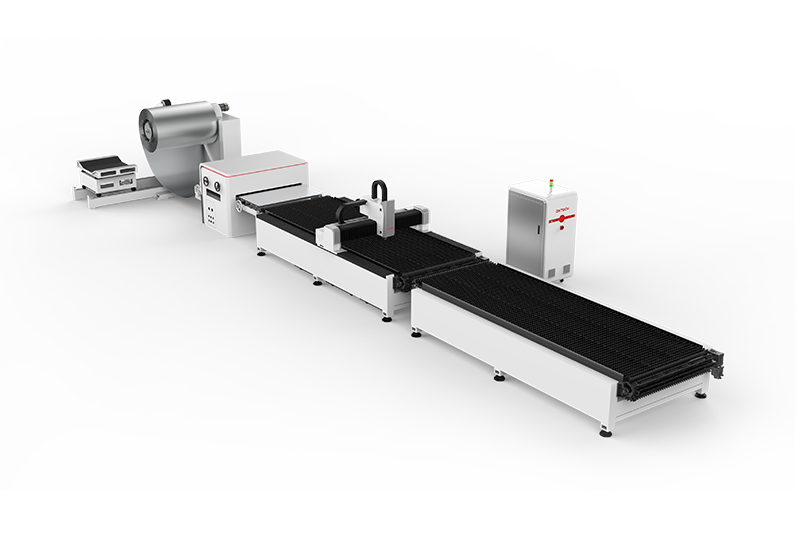

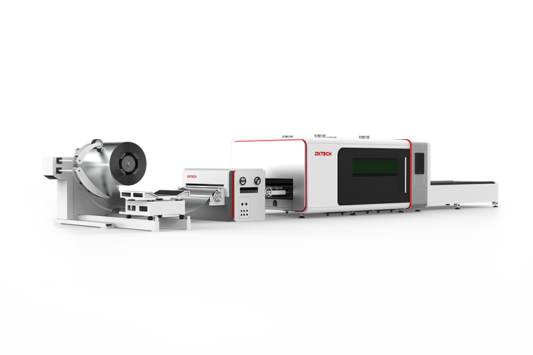

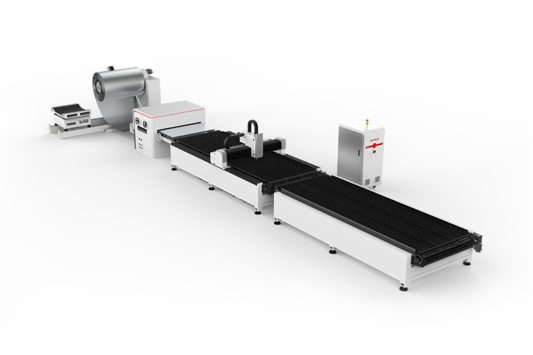

The automatic fiber laser coil cutting machine has a high load-bearing frame, stable operation, steady feeding and flexible operation. It has high power, which is suitable for cutting some thick metal materials, such as stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, galvanized steel, copper, etc. It is widely used in the manufacture of agricultural machinery, textile machinery, food machinery and construction machinery and other large machinery and equipment.

Advantages:

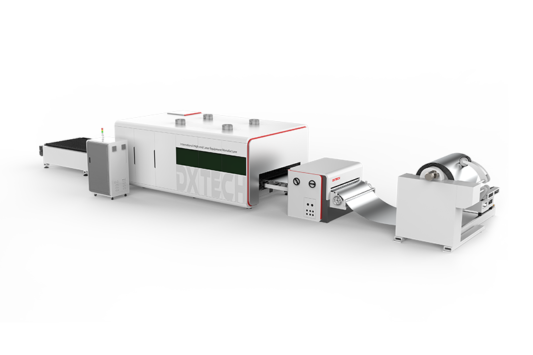

1. The loading material weight can reach 20T, breaking through the feeding limit of ordinary 3T, which is 6 times the efficiency of ordinary feeding equipment.

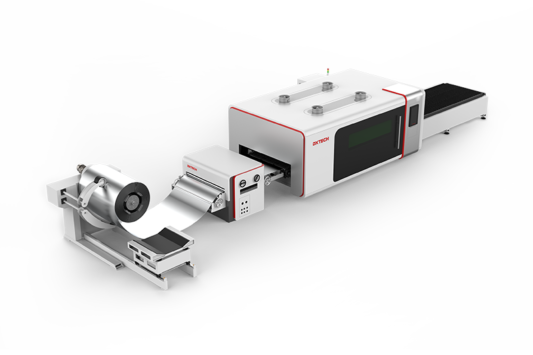

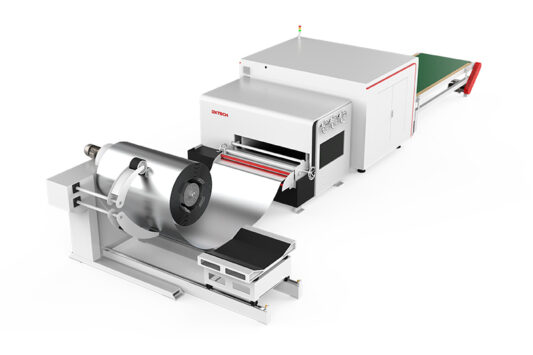

2. Stronger stress relief: after the coil is uncoiled, the sheet metal is leveled by the leveling machine, and the stress of the sheet material during the leveling process is eliminated. So the sheet material is flatter and a better cutting experience is obtained.

3. High-precision transmission structure: using ultra-precision transmission system, the transmission accuracy of sheet metal is about ±0.5MM, which can ensure higher accuracy.

4. Fully automatic assembly line: from feeding – uncoiling – leveling – cutting – unloading, the whole process is automated, which can achieve zero waste of coil material and improve the utilization efficiency of sheet materials.

5. Flexibility: this coil production line breaks through the limit of the ordinary laser cutting length, and has subversive significance in some fields.

Components of

Automatic Fiber Laser Coil cutting machine

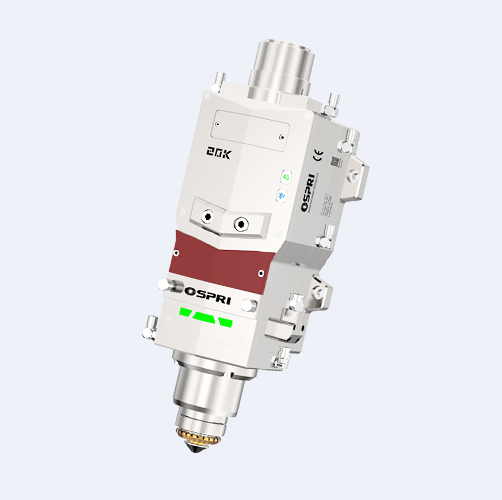

Intelligent focusing laser head

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Aviation aluminum beam

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

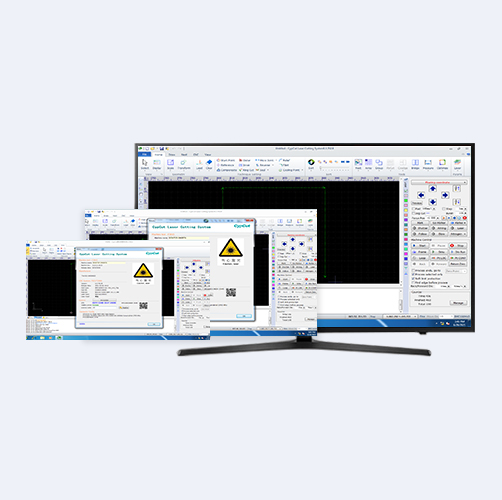

Weihong LS1500/LS3000 Laser Cutting Control System

Weihong laser cutting control system is a software for plane laser cutting. It supports AI, DXF, PLT and international standard G codes generated by Mater Cam, Type3, Wentai, etc.

Except common editing and typesetting functions, it has unique processing sequence browsing and powerful material database to load the specification directly. Besides, operators can control the system through wireless handheld box and Ethernet conveniently.

Reviews

There are no reviews yet.