With the rapid development of science and technology, the automobile manufacturing industry is facing unprecedented changes. In this wave of change, high-precision and high-efficiency production equipment have become an indispensable part of automobile manufacturing. DXTECH sheet metal bending machine, as a shining pearl in the industry, is increasingly used in the automotive industry, providing strong technical support for the rapid development of the automotive manufacturing industry.

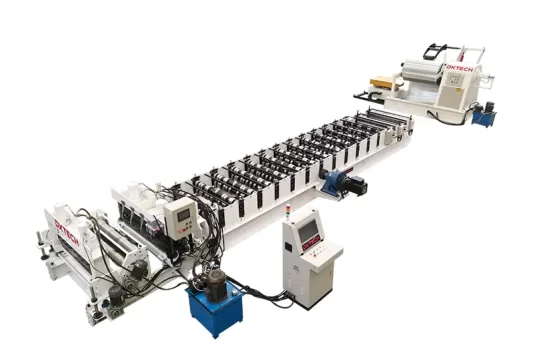

DXTECH sheet metal bending machine provides a perfect solution for sheet metal processing in the automobile manufacturing process with its excellent performance and precise control. In automobile manufacturing, the processing of sheet metal parts is a crucial link, which is related to the appearance quality, structural strength and driving safety of the automobile. DXTECH sheet metal bending machine uses advanced CNC technology to achieve high-precision bending processing, so that the shape and size of sheet metal parts can meet the design requirements, thereby ensuring the overall quality of the car.

In the automotive industry, the application of DXTECH sheet metal bending machines is not only reflected in body manufacturing, but also involves the processing of internal automotive parts. The body is the skeleton of the car, and the processing accuracy of its sheet metal parts directly affects the strength and stability of the body. The DXTECH sheet metal bending machine can accurately control the bending angle and depth to ensure the precise forming of body sheet metal parts, thus improving the safety performance of the car. At the same time, DXTECH sheet metal bending machines also play an irreplaceable role in the processing of interior automotive parts. For example, the processing of components such as instrument panels and door interior panels requires high-precision sheet metal bending technology, and the DXTECH sheet metal bending machine is a powerful assistant in the processing of these components.

In addition to high-precision processing, the high efficiency of DXTECH sheet metal bending machines is also one of the reasons why they are so popular in the automotive industry. In modern automobile manufacturing industry, production efficiency is an important indicator to measure the competitiveness of an enterprise. DXTECH sheet metal bending machine adopts an automated and intelligent operating system, which can achieve rapid mold change and rapid positioning, greatly improving production efficiency. At the same time, the equipment also has a high degree of stability and reliability, and can work continuously for a long time, reducing equipment failure and maintenance time, and further improving production efficiency.

In addition, DXTECH sheet metal bending machines also have flexible processing capabilities. With the diversified development of the automobile market, consumer demands for automobile appearance and performance are also constantly changing. The DXTECH sheet metal bending machine can adapt to the processing needs of different models and different parts. By adjusting parameters and changing molds, it can easily process sheet metal parts of different shapes and sizes. This flexibility makes DXTECH sheet metal bending machines more competitive when responding to market changes.

If you are interested in DXTECH sheet metal bending machine, please contact us!