Application of Laser Machine in kitchen and bathroom Industry

Kitchen and bathroom supplies are usually made of stainless steel metal panels with a thickness of less than 3mm. Cutting for kitchen and bathroom suppliers, secondary processing is necessary. Traditional cutting methods for kitchen and bathroom products create a rough cutting edge and may harm the surface of the products. But using laser cut the supplies will make a smooth and high-finished edge and non-scratched surface that save lots cost of secondary processing. So, in the kitchen and bathroom industry, laser cutting machine is very common.

Applicable Advantages for Kitchen Industry

Many manufacturers use a metal laser cutting machine with fast processing speed, high efficiency and ease of operation. Easy cutting of different shapes of plates, without any change of mold or tool, shortens the preparation time cycle and saves a lot of consumable costs and labor costs.

Laser Cutting Kitchen & Bathroom Supplies

Kitchen and Bathroom products needs high precision in cutting as they have proper fitting sizes in areas where they are assembled. The use of Best Laser cutting machinedoes not require any limitation of the size and shape and that’s why it is best available option for cutting and engraving in 2020. These tasks can be done with the automated setup and cutting of stainless steel materials, pattern graving of metal surfaces, etc. Unlike conventional processing techniques, Metal laser Cutter has the advantages of high cutting accuracy, quick cutting speed, seamless cutting of the end surface and no need for secondary processing. In addition, it cannot be forgotten that the laser cutting process saves a lot of business costs.

Inside kitchen and bathroom supplies, the most popular sheet metal materials 304 and 306 are commonly used in items like hood cooker and Brenner plates. In a range of 0.7-2 mm, the thickness is normally thin. This type of steel sheet material is ideal for cutting with a Best laser cutting machine with a lower power fabric. Best laser cutting machines with an output of 2000W or more can be used for manufacturing of thicker materials such as pool panels and other products.

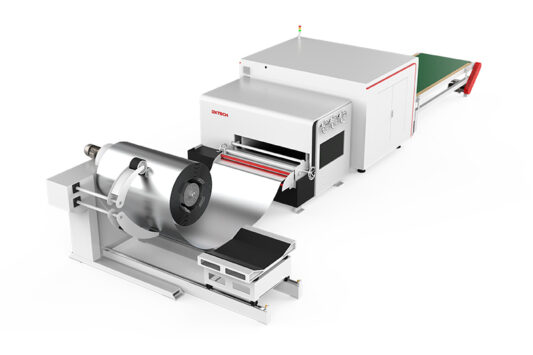

Product Display

These tasks can be done with the automated setup and cutting of stainless steel materials, pattern graving of metal surfaces, etc.

Unlike conventional methods of manufacturing, the benefits of Metal laser Cutter are high precision, rapid cutting speed, fluid cutting surface, without any secondary processing.

In the one side, laser cutting machine would not require molding and cutting to reduce the cost of opening molds substantially. On the other hand, it is no exaggeration to suggest that 10 workers and 10 days are required to complete the product in a typical processing plant. The use of a best laser cutting machine only takes 1 human and 1 day. The laser cutting machine also satisfies the kitchen/bathroom supplies market’s personalized requirements effectively in the age of personalization. Shorter manufacturing period, no need for making shapes, minimizing opening times, no burrs on the surface being manufactured, no need for secondary processing and fast mass production after problem-free proofing.

This is a manufacturing method that primarily involves laser beams of Metal laser Cutter interfered with substances, such as cutting, welding, surface, punching, and micro-machine materials (including metals and non-metals).Metal laser Cutter involves Laser handling with non-contact processing benefit, small work piece effect, high performance, no emissions, high accuracy and a small area with heat effect. It is also perfect for the development of lightweight and lovely home appliances in the Kitchen and WC industries in particular. For example, in plastic sections of washing machines, coolers and air conditioners, cutting, welding in alloy casing, boiling and branding.

Laser Cutting Process

The method works through the material you are looking to cut, having a targeted and precise laser beam to ensure an accurate and flawless finish. At first Metal laser Cutter pierces the substance at the edge with a hole and from there on the beam begins.

Metal laser Cutter literally burns the substance that is passing through, which is more like frying than cutting.