Application of Laser Machine in shipbuilding Industry

The ongoing advancement of shipbuilding technologies has contributed to significant improvements in shipbuilding materials and in the construction of ships. The use of Fiber laser cutting machine in shipbuilding is specific and closely connected to the processing and operation characteristics of ships and the characteristics of the Industrial laser cutter production method.

Applicable Advantages for Shipbuilding Industry

- Fiber laser cutting machine achieve accuracy levels and edge efficiency that are incomparable to other cutting methods.

- The Industrial laser cutter beam does not wear during the laser cutting process.

- This technology is capable of cutting complicated shapes.

- The techniques of cutting are quicker.

- Contamination of the cut material shall be reduced

Laser Cutting Ship Building Supplies

The ongoing advancement of shipbuilding technologies has contributed to significant improvements in shipbuilding materials and in the construction of ships. The use of the fiber laser cutting machine to the shipbuilding industry has its individuality, and is closely connected to the manufacturing and application characteristics of the ship itself. The unique high precision and plasticity of the fiber laser cutting machine are very compatible with the shipbuilding industry. So what are the basic uses of fiber laser cutting machine in the shipbuilding industry? In recent years, ‘precision shipbuilding’ and ‘fast shipbuilding’ have been the major developments in the growth of the shipbuilding industry. Fiber laser cutting machine technology has evolved exponentially, accounting for more than 70% of the global laser processing market. The shipbuilding industry is primarily focused on steel plate raw materials, using industrial laser cutting plates, which dramatically shortens the manufacturing time and lowers costs relative to the previous processing technology of punching machines.

The specifications for industrial laser cutting in the shipyard are rising increasingly due to the shortage of Professional and higher labour rates technicians. Many forms of fiber laser cutting machines in ship-building are in use such as V bevel cutting, CVBA, pipe-hole cut and 3mm slit cutting for building hole cutting and water drain cutting. There are many different models of laser cutting machine. In order to cut down time and machine motion, Koike has concentrated on creating every bevel cutting process. Software production for industrial laser cutting carried out in conjunction with the programming of each bevel cutting process, in order to prevent non-tolerance to component dimensions. For eg, bridge cutting has been included in the automated programming process since the Y bevel cutting with land involves two cutting passes. Koike has produced the appropriate shape for laser bevel cutting with automated programming capabilities. Many shipyards have appreciated this growth and have ordered a range of machines.

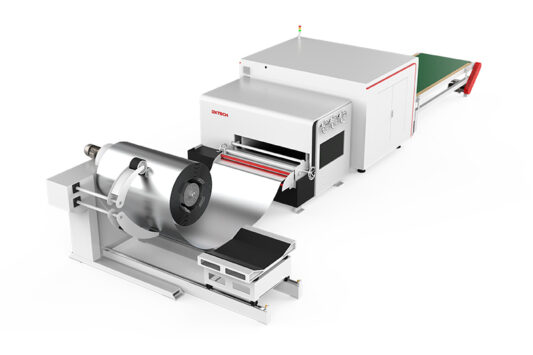

Product Display

As same to the automotive industry the ship building also requires high precision cutting in its engine section so any malfunctioning could be avoided so for this eiber laser welding machine with high intensity is required so it can cut the gears and mechanical parts in such a way that it can be lasting and resistance proof.