Laser Cleaning Machine

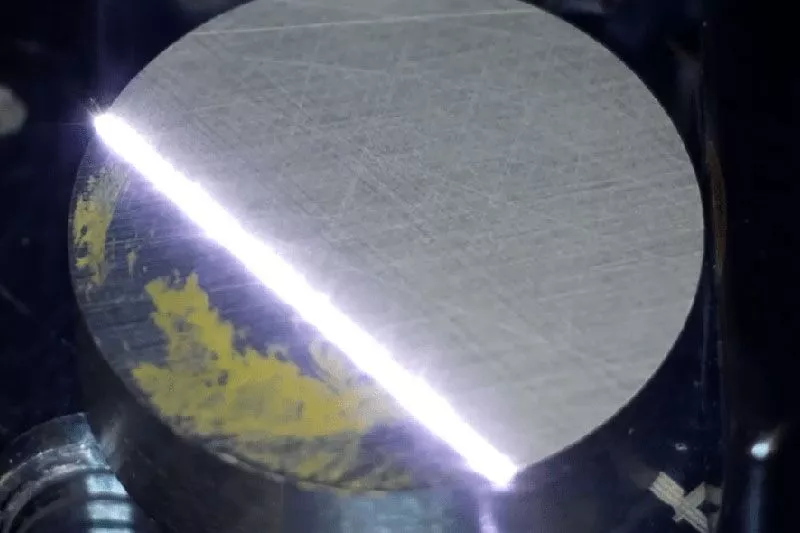

Laser cleaning machine (also known as laser rust removal machine) represents the most high-end industrial cleaning technologies. Laser cleaning machine generates high-density pulsed laser beam which irradiates on the surface of the work piece and removes the rust, dust, oil, grease, oxidation, painting, coating and other contaminants very quickly.

show more

Laser cleaning machine is widely used in all walks of life. Its applications include rust removal on metal surface, oil stains and dirt cleaning, painting and coating removal, pretreatment of welding surface and spraying surface, dust removal on stone statue, cultural relic restoration, rubber mold residue cleaning, etc.

Laser cleaning machine becomes more and more popular in automobile industry, electronics industry, tire industry, shipbuilding industry, rail transit, aerospace, rubber mold industry, construction, cultural relics protection, machinery manufacturing, food processing, petrochemical industry, etc.

show less

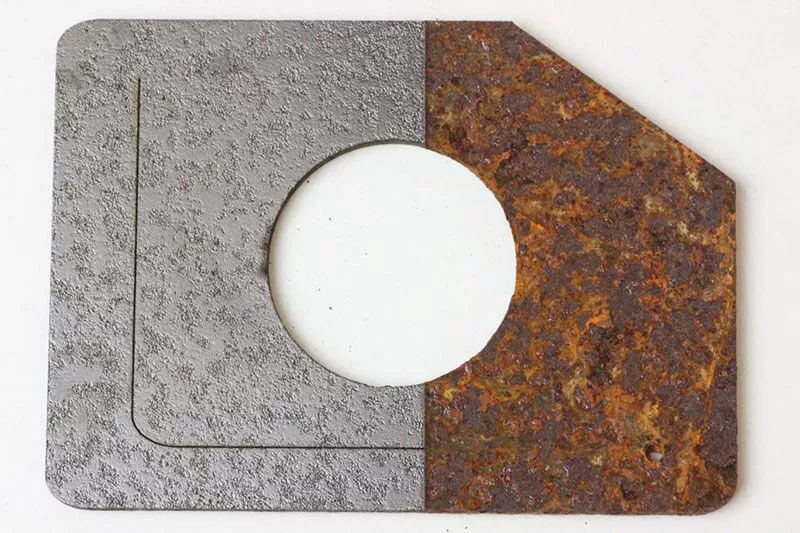

Laser cleaning machine samples

Laser cleaning machines are widely used in mold cleaning, industrial rust removal, old paint and film removal, pre-welding pretreatment and post-welding treatment, degreasing of precision parts, decontamination and oxide layer removal of electronic components, cleaning of cultural relics, etc. Widely used in metallurgy, moulds, automobiles, hardware tools, transportation, construction appliances, machinery and other industries.

We provide free proofing, welcome to consult.

Specifications

|

BRAND |

DXTECH |

|

Application |

Laser Cleaning (for rust, painting, oil, coating, dirt, etc.) |

|

Applicable Material |

Stainless Steel, Carbon Steel, Aluminum, Metal, Stone, Ceramics, Rubber, etc. |

|

Laser Source |

Fiber Laser |

|

Pulse Type |

Continuous Pulse Laser |

|

Laser Power |

20W, 30W, 50W, 100W, 200W, 500W, 1000W or as requested |

|

Working Environment |

Flat, no vibration, no impact |

|

Power Adjustment Range |

0%-100% (gradually adjustable) |

|

Pulse Width |

≤20ms |

|

Scanning Width |

0-120mm |

|

Fiber Length |

5m (10m can be customized) |

|

Move Method |

Handheld; Automatic |

|

Laser Wave Length |

1064nm |

|

Repeat Frequency |

20-50kHz |

|

Working Voltage |

380V/50HZ or 220V optional |

|

Working Temperature |

0℃~40℃ |

|

Working Humidity |

≤80% |

|

Cooling Mode |

Air Cooing; Water Cooling |

Laser cleaning machine is an automatic equipment that releases high-energy pulsed laser beam to irradiate and remove the rust, dust, contaminant, painting and oxide on the surface of the work piece. The principle of laser cleaning technology is that the contaminants on the surface of the work piece melt or evaporate instantly after being irradiated by the pulsed laser beam, so that the surface of the work piece becomes clean. Laser cleaning is efficient and eco-friendly. It is becoming more and more popular in various industries.

The efficient laser cleaning lies in the fiber laser generator which releases high-density fiber laser beam. Traditional industrial cleaning methods usually use chemical reagents or mechanical methods to remove the contaminants on the surface of the work piece. These methods have some disadvantages, such as low efficiency, damage the substrate or generate additional contaminants. Moreover, with the increasingly strict environmental protection laws, there are fewer chemicals that can be used in the industrial cleaning. Therefore, looking for an eco-friendly cleaning method is a major problem for many companies.

The table below is a comparison of various cleaning methods. Compared with the traditional mechanical cleaning method, chemical cleaning method and ultrasonic cleaning method, laser cleaning does not require any organic solvents and is pollution-free. The laser cleaning process has no noise and no damage to human body and environment.

|

Cleaning Methods |

Laser Cleaning |

Ultrasonic Cleaning |

Dry Ice Cleaning |

Chemical Cleaning |

Mechanical Grinding |

|

Cleaning medium |

Laser |

Cleaning agent |

Dry ice |

Chemical cleaning agent |

Mechanical/abrasive paper |

|

Contact cleaning or non-contact cleaning |

Non-contact |

Contact |

Non-contact |

Contact |

Contact |

|

Work piece damage |

No damage |

No damage |

No damage |

Damage |

Damage |

|

Cleaning efficiency |

High |

Middle |

Middle |

Low |

Low |

|

Consumable |

Only electricity |

Cleaning agent |

Dry ice |

Chemical cleaning agent |

Abrasive paper, grinding wheel, whetstone, etc. |

|

Cleaning effect |

Excellent, high cleanliness |

Good, small clean area |

Good, uneven |

Medium, uneven |

Medium, uneven |

|

Cleaning precision |

Precise and controllable, high precision |

Cannot specify cleaning range |

Uncontrollable, low accuracy |

Uncontrollable, low accuracy |

Uncontrollable, medium accuracy |

|

Safety and environmental protection |

No chemical pollution |

No chemical pollution |

No chemical pollution |

Chemical pollution |

Rust/debris pollution |

|

Manual operation |

Simple operation, handheld or automated |

Simple operation, need to manually add consumables |

Simple operation, handheld or automated |

Complicated processing flow, high requirement on operator, require pollution prevention measures |

High manpower consumption, require pollution prevention measures |

|

Cost |

High initial investment, no consumables, low maintenance cost |

Low initial investment, medium consumables cost |

Medium initial investment, high consumables cost |

Low initial investment, high consumables cost |

High initial investment, high consumables cost, high labor cost |

The invention of laser cleaning technology opens a door for enterprises and individuals by virtue of its non-contact processing, environmental protection, low processing cost and low thermal effect. Laser cleaning machine is the best solution for industrial cleaning.

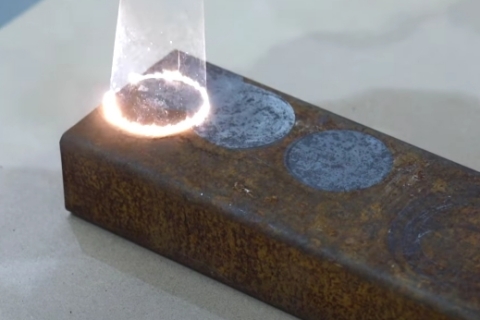

Laser cleaning machine uses laser ablation principle to remove the dust on the metal surface. Laser ablation is a type of physical reaction. When the high-density laser beam irradiates on the metal surface, it is absorbed by the pollution layer on the metal surface. The absorption of large energy forms a rapidly expanding plasma which generates shock waves, and the shock waves turn the pollutants into fragments and remove them off the metal surface. The laser ablation reaction occurs in this way and makes the rust, dirt and oxide layer melt and evaporate very quickly.

Different materials have different properties, so each material has a specific ablation threshold. As long as the energy of laser beam is above the ablation threshold of the dust that needs to be removed, the laser beam can successfully remove the dust. The ablation threshold of rust, oil or painting is much lower than metals like stainless steel, carbon steel, aluminum, etc. Therefore, if the laser parameters are set reasonably, the laser cleaning process will not damage the substrate and leave a very clean surface.

As the laser cleaning machine uses laser ablation to remove dust, there is no consumables required during the laser cleaning process. The traditional industrial cleaning methods like chemical cleaning, ultrasonic cleaning or dry ice cleaning need cleaning reagent to finish the cleaning process, which improves the processing cost and labor cost. Laser cleaning method solves the problem perfectly and it is pollution-free. More and more enterprises prefer use the laser cleaning machine to clean metal parts and restore equipment surface.

Compared with the traditional industrial cleaning methods, laser cleaning machine has the following advantages:

- Non-contact cleaning and no damage to the substrate. The traditional cleaning methods usually contact with the work pieces directly and may damage the surface of the material. Besides, the cleaning agents adhere to the substrate and cannot be removed. Laser cleaning is a non-abrasive and non-contact processing method which solves those problems very easily.

- No consumables, no chemical agents and environmental friendly. The laser cleaning method is to release laser beam and let the contaminants melt and evaporate, so the laser cleaning doesn’t need any chemical agents and other cleaning agents. The removed rust is small solid powder which is easy to store or recycle. Laser cleaning method has no pollution to the environment and is an ideal way for green cleaning.

- Excellent cleaning precision and controllable process. Laser cleaning process has high cleaning precision and produces excellent effect on the work piece. It can not only clean flat surface, but also clean curved surface, groove and the inside of pipe. The processed work piece has high cleanliness and no damage. Laser cleaning is automatic and easy to control. The laser output width can be set for precise cleaning. Users can adjust the laser parameters to suit different operating environments and cleaning requirements.

- Simple and automatic operation. Laser cleaning machine is very easy to install and operate. A handheld laser cleaning machine usually has a compact size and is easy to reach curved surface and complex geometric shapes. Users can hold the cleaning head and clean the specific position on the work pieces per their needs. The cleaning head weights about 2kg-4kg. Also, according to the diversified requirements of users, laser cleaning machine can be hand-held or coordinated with robot to achieve an automated cleaning.

- High cleaning efficiency and time-saving. The speed of laser cleaning is faster than traditional cleaning methods. A laser cleaning machine can work at 15-30 m2/h speed and perform high quality cleaning at the same time.

- Reliable laser beam quality and long machine service life. DXTECH laser generator has high quality and generates continuous high-density laser beam. With the complete quality control management system and strict machine manufacturing standards, DXTECH laser cleaning machine has a long service life and can help users clean various metal parts, molds, equipment and stones for a long time.

- Low processing cost and low labor cost. Laser cleaning doesn’t need any chemical agents or other consumables, so its processing cost is low. Users just need to provide electricity. Moreover, laser cleaning machine is easy to operate and saves labor cost. Users don’t need to disassemble and move molds when they want to clean the molds. They just need to hold the cleaning head and clean any parts that they want.

Laser cleaning machine has the characteristics of non-contact, no thermal effect, no mechanical force on metal surface, no consumables and low processing cost. This machine has been widely used in many industries. So how to use a laser cleaning machine after you buy one? Here are the main steps for your reference. Please always remember that you need to read the operation brochure provided by the manufacturer to understand the precautions and operation instructions. Wear protective glasses and other protective equipment to ensure your safety. And do not look directly at the laser output position with you eyes during the cleaning.

- Check the machine parts and make sure nothing is damaged or missing, and no dust or dirt on the machine. Check the power supply of the machine and make sure it is grounded.

- After checking the machine, insert the plug into the power socket. Turn on power switch and set parameters on the control panel.

- Take out the cleaning gun and open the cover, aim the gun head at the work piece that you need to clean and start your cleaning work.

- After the cleaning process, release the gun button, turn off the laser switch, turn off the power, insert the cleaning gun back into the storage box, and then unplug the power plug.

- If you encounter any problems during the operation, please seek help from after-sales engineer and do not disassemble the machine by yourself. Unauthorized disassembly and assembly may damage the machine or bring danger to the operator.

During the operation of a laser cleaning machine, the processing materials usually generate a large amount of corrosive dust and smoke. These dust and smoke are deposited on the surface of the guide rail and linear shaft for a long time. If we don’t clean them timely, they will affect the machine’s cleaning accuracy. What’s more, these dust and smoke will form corrosion points on the surface of the guide rail and shorten the machine’s service life. Therefore, to keep the laser cleaning machine work normally, stably and ensure the cleaning quality, we need to maintain the machine timely and regularly. We can follow below tips to maintain the laser cleaning machine.

- Clean the machine surface and lubricate the guide rail regularly. Before using the machine, remember to check and clean the machine surface, remove the debris on the table, stopper and guide rail. Lubricate the guide rail timely.

- Clean the water chiller regularly. For water cooling mode, clean the water chiller regularly every half a month, drain the internal dirty water and then fill up with fresh pure water. Dirty water will affect the laser output effect, so we need to clean the water chiller regularly.

- Clean the reflector and focusing lens. The reflector and focusing lens need to be scrubbed with special cleaning fluids every 6-8 hours. When scrubbing them, use a cotton swab to scrub in a counterclockwise direction from the center to the edge. And be careful not to scratch the lens when you scrub them. In addition, after the cleaning, re-adjust the focal length of the lens.

- Clean the exhaust fan and smoke pipe. If there is a large amount of smoke during the cleaning, that means you need to clean the fan and pipe. Remove the fan cover and scrap the fan blades and air channel with thin wood, and then blow off the dust with a high-pressure gun.

More and more companies and individuals want to buy a laser cleaning machine to support their business. How to buy a suitable laser cleaning machine that fits your needs? You can follow the below three steps.

- First of all, contact with a qualified manufacturer that has profound experience in the manufacturing of laser cleaning machines. A reliable manufacturer not only produces high quality laser cleaning machines, but also provides you complete machine data and thoughtful after-sales service. Before you buy a machine, it is essential to inspect the factory and check the real cleaning effect of the machine.

- In addition, check the machine’s appearance. The design, structure and manufacturing process can almost directly determine the quality of the machine. The design style of each manufacturer is different. A manufacturer that has mature production technology always continuously improve the machine’s appearanceand structure under the premise of ensuring quality.

- Choose the machine according to your needs and budget. Tell the salesperson about your cleaning requirements and budget plan, and they will recommend the suitable machine and configure the parameters, machine size and parts. Let the salesperson know your detailed processing requirement (processing materials, cleaning speed, etc.) so that you can get a most cost-effective laser cleaning machine.

DXTECH Quality Assurance

2 years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.