Application of metal laser cutting machine in automotive industry

Over the last few years the demand of the global car industry is rising day by day, as well as the phase of automotive intelligence. The replacement of the automotive manufacturing industry also requires more and more sophisticated manufacturing processes to sustain it. Among them the laser process is one of the most ideal and present manufacturing needs, and the convergence of advanced laser CNC machine for metal and automotive production is a development of the days.

Laser CNC machine for metal also provided suppliers with more opportunities when supporting the growth of the automotive industry. Laser CNC machine for metal is more compact and effective and easier to automate compared with conventional manufacturing methods and is fit to the core specifications of automobile production. Laser technology in the fields of cutting, welding and branding has evolved in the automotive industry.

Applicable Advantages for Automotive Industry

- Smooth cuts – no edge rework needed

- Quite high repetition precision

- Single operation laser cutting and graving

- Therefore no tool wear, reliably high quality cut

- Strong versatility in contour selection without the need for the construction or adjustment of the instruments.

Laser Cutting Automotive Supplies

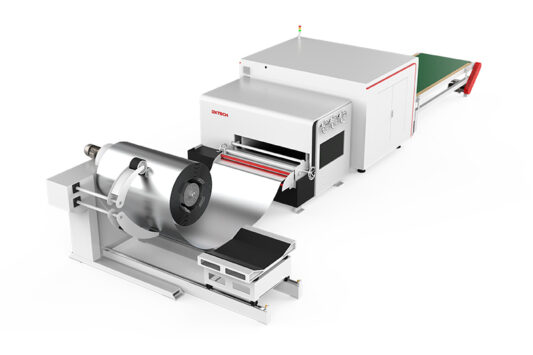

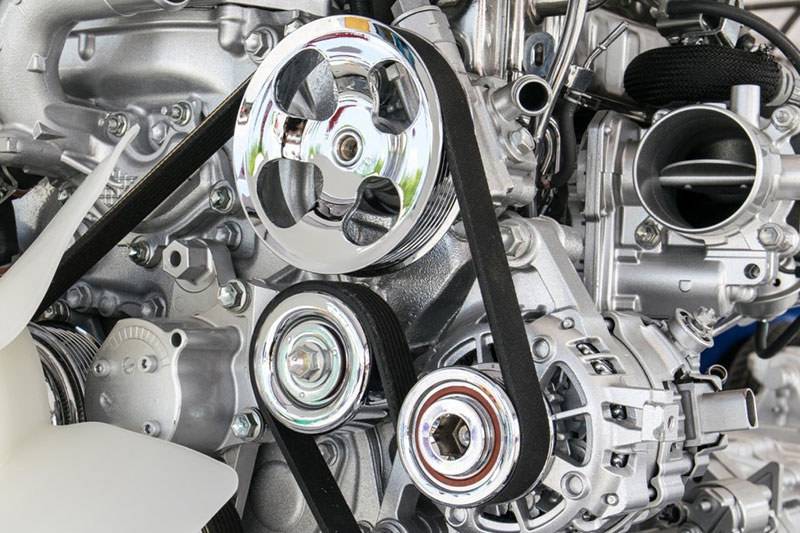

Industrial Laser cutting machine includes nearly all uses in the automotive industry including vehicle parts, car bodies, car door frames, car trunks, automotive roof covers, etc. 60% to 80% of automotive components are completed by laser processing in industrialized industrial countries. One of the most common laser uses is laser cutting. Laser CNC machine for metal involves flat sheet cutting and 3D tubing. Fiber Laser cutting machine is common in the car industry.

Fiber Laser cutting machine is one of the most commonly used techniques in the automotive industry and other production industry with its unique benefits with only one moment aside. The method of cutting materials and shapes down to scale is commonly used to produce sophisticated and difficult objects. Industrial Laser cutting machine itself however, presents a revolutionary alternative to most conventional forms of cutting on the market. Most certainly, with seamless boundaries, an improved end goods and material waste control, consumers can have incredibly detailed finishing. Industrial Laser cutting machine often uses a very low power consumption, has low maintenance costs and can be used for many applications, and also decreases time consumption.

Finally, the process is one of the best. Fiber Laser cutting must be performed in a closed, tight light box, while a freely moving blade performs the cutting using more common and conventional techniques. Although precautions are taken to guarantee the safety of traditional processes, industrial Laser cutting machine cutting clearly gives manufacturers less reason for concern.

Product Display

Car Emblems and including many other high definition parts require high precisions and accuracy which can only be possible with the help of industrial Laser cutting machine.

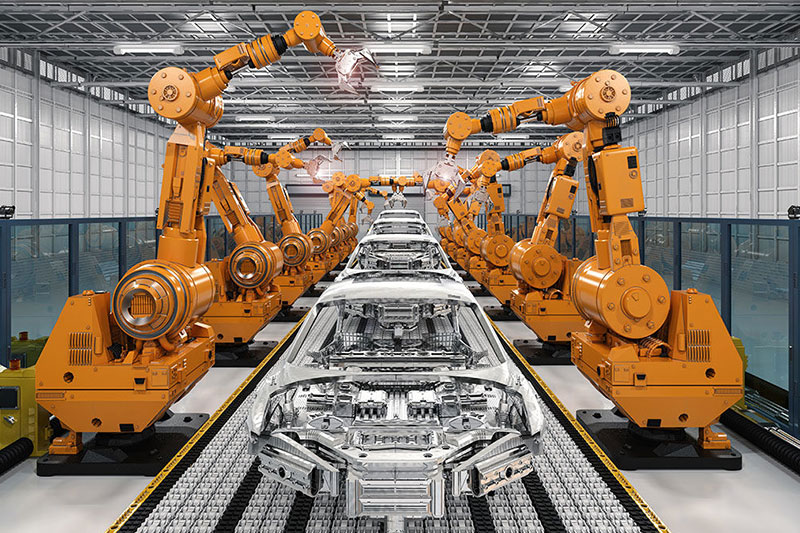

Japan’s Nissan Motor Corporation has managed to boost the paint of glass by using a laser surface-treated stain layer. In front of a thin layer of stainless steel, the surface is grated by a laser beam, the steel surface forms a uniform diameter and depth of innumerable small area, and then a paint treatment. The manufacturing of the dashboard shell with carbon dioxide 400W power play save $ 600,000 a year. Volkswagen uses a mix of laser and robotic technologies that can save $ 600,000 in processor cost per year. The use of fiber laser cutting machine devices to monitor the welding process by another German car manufacturer that uses carbon dioxide laser welding galvanized steel to increase manufacturing performance greatly.

Laser Cutting Process

The approach works through the material that you are attempting to cut, with a targeted and precise laser beam to ensure an effective and smooth finish. At first the industrial Laser cutting machine pierces the material at the edge with a hole and the beam starts from there.

Fiber laser cutting basically burns the material that goes through, which is more like cooking than cutting. This allows lightweight materials like cloths to be easily cut onto durable metals and gemstones like diamonds.