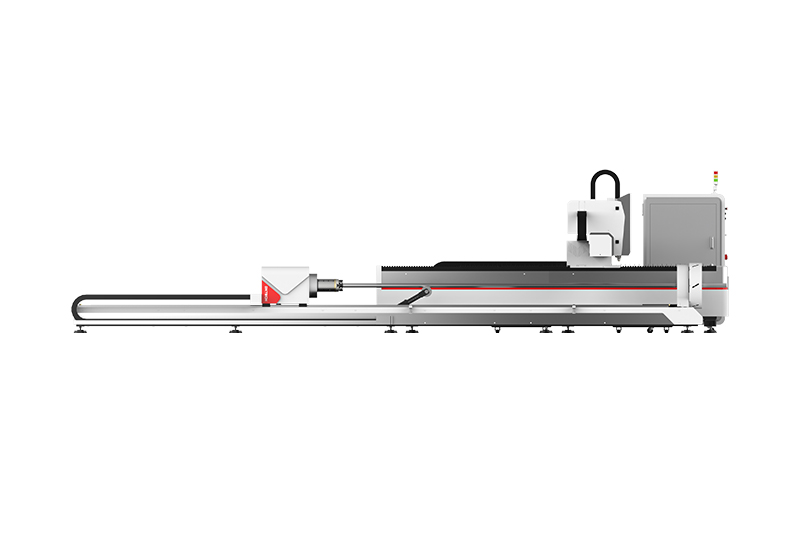

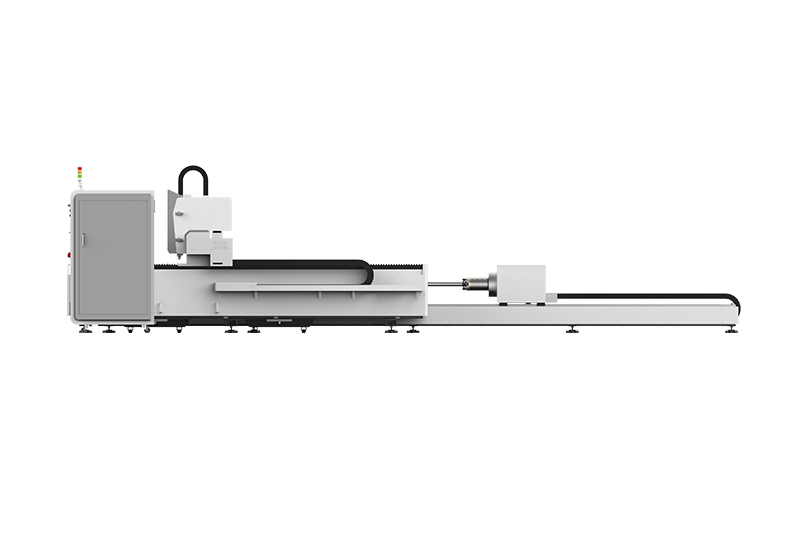

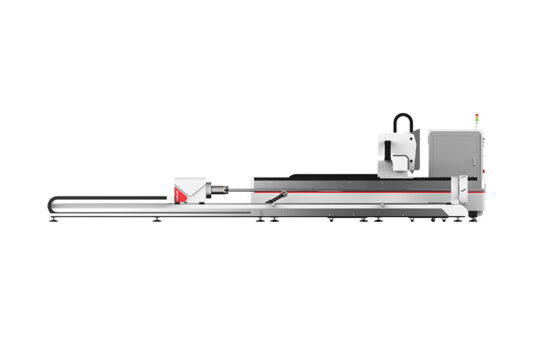

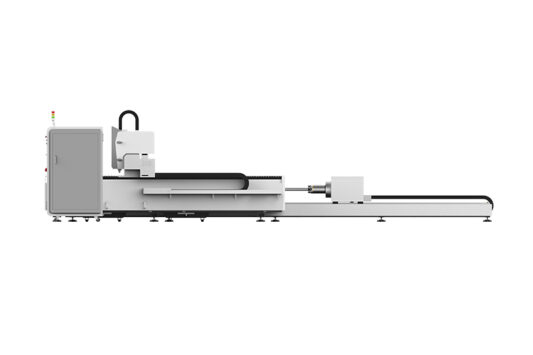

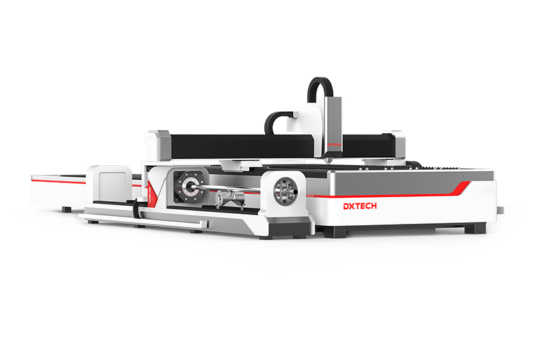

This metal sheet and tube fiber laser cutter is the best choice for processing complex metal pieces. It can not only process metal sheets with fast speed and good accuracy, but also process metal tubes and make precise cuts. DXTECH equips this metal sheet and tube laser cutter with world-class components, such as Raycus/Max laser source, Japan Yaskawa/Fuji servo motor, Taiwan HIWIN/PMI guide rail, France Schneider electronic components, etc. The working size and laser power can be customized according to the customer needs. This machine has wide applications in the auto parts, robot parts, rocket parts, aircraft parts, ship parts, household appliance parts, metal tools, engineering machinery parts, agricultural machinery parts, metal decoration, metal furniture, kitchen countertop, kitchenware, fitness equipment industries.

Video

Advantages

- With the metal sheet processing platform and metal tube cutter, this machine can process both metal sheets and tubes and saves purchase cost for users.

- Adopted high-quality Raycus/Max laser source and world-class laser cutting head, the machine releases high-quality laser beam and makes precise cuts on metals.

- Equipped with heavy cast iron bed, this machine works stably and does not deform within 20 years.

- Manufactured with aviation aluminum beam, the cutting speed is very fast and the processing accuracy can be guaranteed at the same time.

Components of metal sheet and tube fiber laser cutter

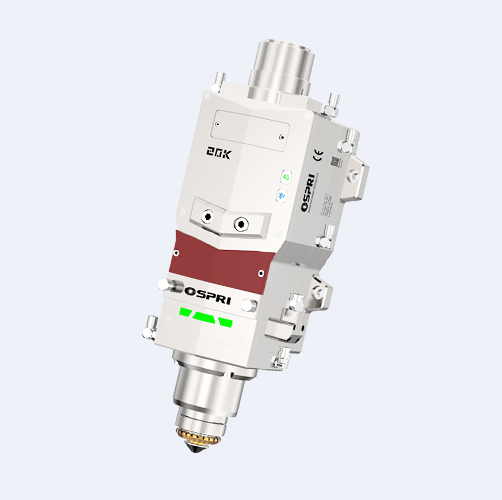

Intelligent focusing laser head

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Aviation aluminum beam

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

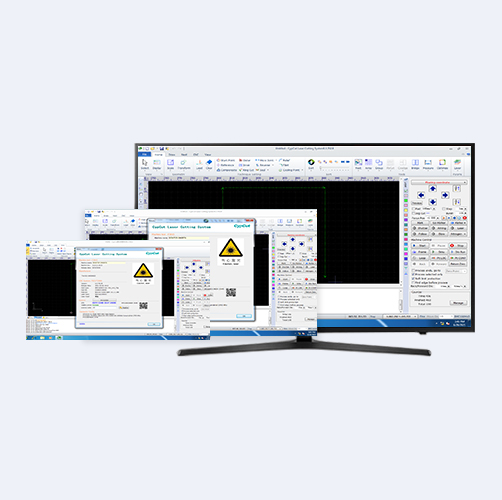

Weihong LS1500/LS3000 Laser Cutting Control System

Weihong laser cutting control system is a software for plane laser cutting. It supports AI, DXF, PLT and international standard G codes generated by Mater Cam, Type3, Wentai, etc.

Except common editing and typesetting functions, it has unique processing sequence browsing and powerful material database to load the specification directly. Besides, operators can control the system through wireless handheld box and Ethernet conveniently.

FAQ

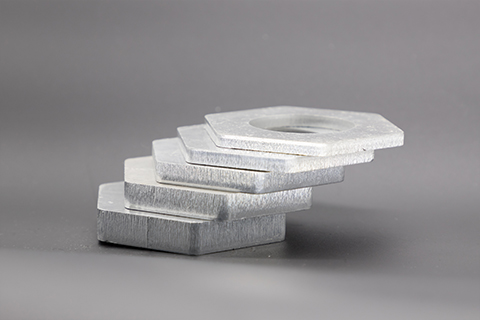

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.