Application of Laser Machine in sheet metal Industry

In multiple fields, a fiber laser cutting machine has excellent performance. For sheet metal processing firms, the processing of sheet metal material is important, however the fiber laser cutting machine system is still very heavy. The machinery of sheet metal processing is still very demanding. A major cutting machine is normally used for cutting in which the exact quality of processed materials is not high but the cost is high before the arrival of a laser cutting machine. But the fiber laser cutting machine can be processed and performance vastly improved by means of laser cutting machines, with the advent of laser cutting machines. In fiber laser cutting machine, the benefits of sheet metal cutting are evident in contrast to conventional metal cutting machines. It is more reliable, more accurate, more operational and quicker to cut. The use of fiber laser machine for grinding metals, especially carbon zinc, steel, non-ferrous metals, aluminum and other metals

Applicable Advantages for Sheet Metal Industry

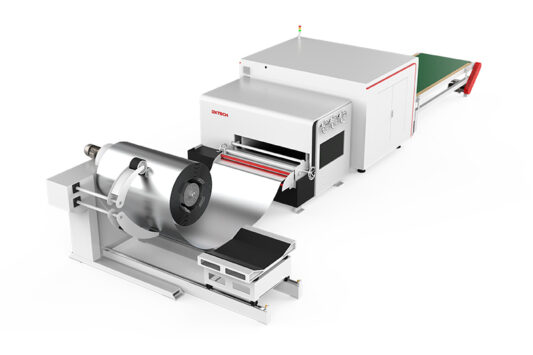

The benefits of fiber laser cutting machine are quick cutting speed, high accuracy, good beam efficiency and the business of sheet metal manufacturing of different plates can be pursued. Industrial laser cutting is designed to increase the performance of today’s metal chassis manufacturing industry. The fiber laser cutting machine is a laser beam emitted from the laser chip, which is focused by the optical path mechanism on a high power density laser beam. The laser beam is irradiated to the surface of the work piece so that the work piece reaches the melting point or boiling point, and the high-pressure coaxial gas blasts away the melted or vaporized metal. The material is eventually broken, in order to achieve the cutting target, by moving the relative location of the beam and the component.

Laser Cutting In sheet metal Industry

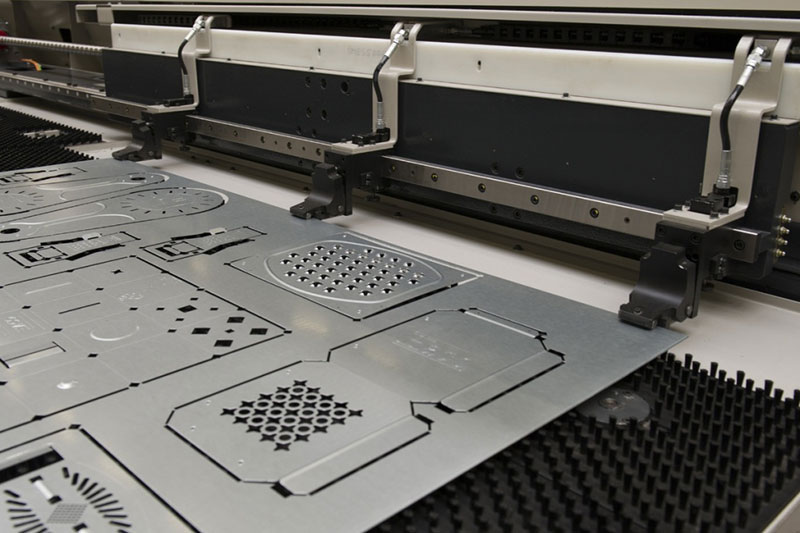

Laser cuts are very effective and precise and can be operated very quickly. It has more advantages than computer cutting, such as quick cutting speed, narrow slit, cutting finish, mild deformity, and heat zone. Compact and high-efficiency, cutting characteristics are not restricted to flat, but are gradually three-dimensional.

High performance in laser cutting: the fiber laser cutting machine typically have several CNC worktable systems due to the propagation properties of the laser and the complete cutting operation is entirely CNC regulated. When handling only the numerical control software must be modified, it can be paired with the trimming of various formed pieces, which not only can be trimmed twice, but can also be trimmed.

The cutting machine, used primarily in the kitchen, industrial, advertisement, machine and publicity business for cutting laser sheet metal to stainless steel. The industrial laser cutting system for stainless steel manufacturing will save human and material capital efficiently. The cutting speed is very quick and high quality, which is twice the speed of the normal line cutting. The mass manufacturing of the business can be carried out conveniently by the consumer following delivery. The sheet metal laser cutting machine. Also very effective is the use of the sheet metal laser cutting system to cut carbon steel. The industrial laser cutting machine can be operated in either direction by the computer system using sheet metal laser cutting machines. The consumer will import into the machine the original figure and automatically cut the cutting head according to the system configuration.

Product Display

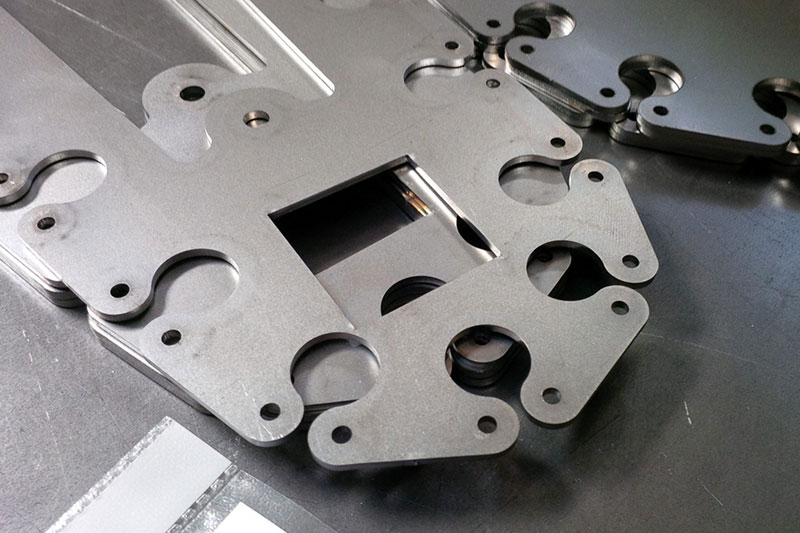

Shaping Sheets

With the help of industrial laser cutting we can shape the sheets as the way we want to shape them.

Cutting sheets

Cutting sheets in different designs and textures also be done easily with the help of industrial laser cutting machines in 2021.

Engraving

Whereas we can also done engraving in sheets metals with the help of fiber laser machine.

Laser Cutting Process

1: The fiber laser machineincidence is narrow and narrow, the surface is perpendicular to both sides of the slit and measuring precision can exceed +0,05mm on the cut sections.

2: The cutting surface is flawless and perfect, the surface roughness is just ten microns and the final process without a mechanical process is laser cutting, and the pieces can be used straightaway.

3: After the material was cut by fiber laser machine the thermal zone was very thin, and the work piece deformation was virtually uninfluenced by the feature of the material, cutting precision was high, slit geometry was good and slit cross section shape will be more normal.