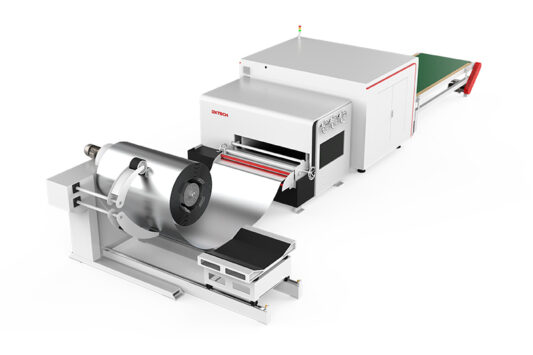

With the rapid development of industrial technology, laser cutting technology occupies a pivotal position in the manufacturing industry due to its high efficiency and high precision. However, the problem of gas pollution generated during the laser cutting process has become increasingly prominent, becoming a bottleneck restricting its further development. Therefore, how to effectively prevent and control laser cutting gas pollution has become an urgent problem in the industry. As an advanced cutting equipment, the DXTECH laser cutting machine has shown significant advantages in gas pollution prevention and control.

During the laser cutting process, due to the high temperature and high speed of the laser beam, the material is rapidly melted and vaporized, thus producing a large amount of smoke and harmful gases. These smoke, dust, and gases not only seriously pollute the working environment, but also pose a threat to the health of operators. Therefore, the primary task of preventing and controlling laser cutting gas pollution is to reduce the generation of smoke and harmful gases.

DXTECH laser cutting machines have taken many innovative measures to reduce the generation of smoke, dust, and harmful gases. First of all, it uses advanced cutting technology and parameter optimization to achieve efficient and precise cutting of materials by precisely controlling the power and speed of the laser beam, thus reducing the generation of smoke and harmful gases. Secondly, the DXTECH laser cutting machine is equipped with an efficient smoke and dust collection system. Through powerful dust suction devices and filtering equipment, the generated smoke and dust are quickly collected and filtered, greatly reducing the pollution of smoke and dust to the environment. In addition, DXTECH has also developed an intelligent exhaust gas treatment system, which can adsorb, filter, and decompose harmful gases, effectively remove harmful substances, and make the exhaust gas meet emission standards.

In addition to reducing the generation of smoke, dust, and harmful gases, DXTECH laser cutting machines also focus on the reuse of waste gas after treatment. It uses advanced flue gas recovery technology to recycle useful components in the exhaust gas, which not only reduces energy waste but also reduces environmental pollution. This recycling method not only conforms to the concept of sustainable development but also brings economic benefits to the enterprise.

Of course, preventing and controlling laser cutting gas pollution is not something that can be accomplished overnight, and needs to be addressed from many aspects. On the one hand, companies need to strengthen safety training for employees, improve operators’ safety awareness and operating skills, and avoid leaks of smoke and harmful gases caused by improper operations. On the other hand, the government and all sectors of society should also increase investment and support in the prevention and control of laser cutting gas pollution, promote the research and development and application of related technologies, and provide a strong guarantee for the sustainable development of the laser cutting industry.

To sum up, preventing and controlling laser cutting gas pollution is a long-term and arduous task. DXTECH laser cutting machines provide effective solutions for preventing and controlling laser cutting gas pollution by using advanced cutting technology, smoke collection systems, and exhaust gas treatment systems. However, realizing the green and sustainable development of the laser cutting industry also requires joint efforts and continuous innovation of the government, enterprises, and all sectors of society.

If you are interested in DXTECH laser cutting machine, please contact us!