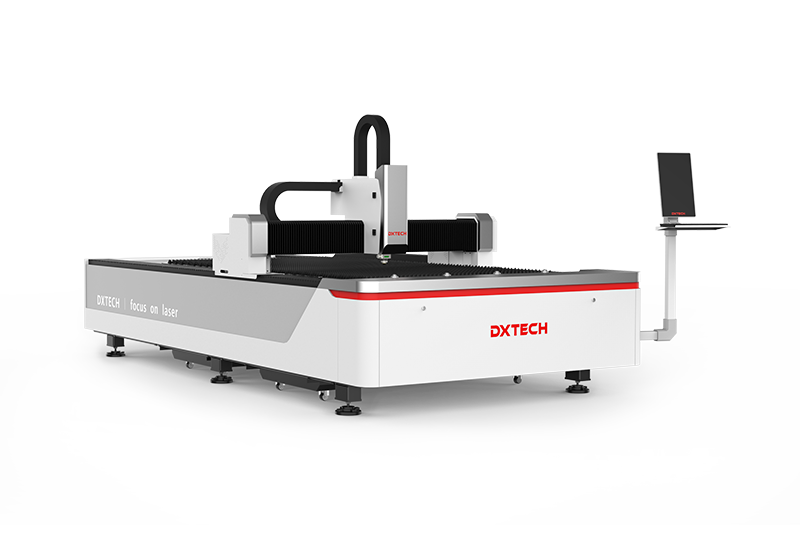

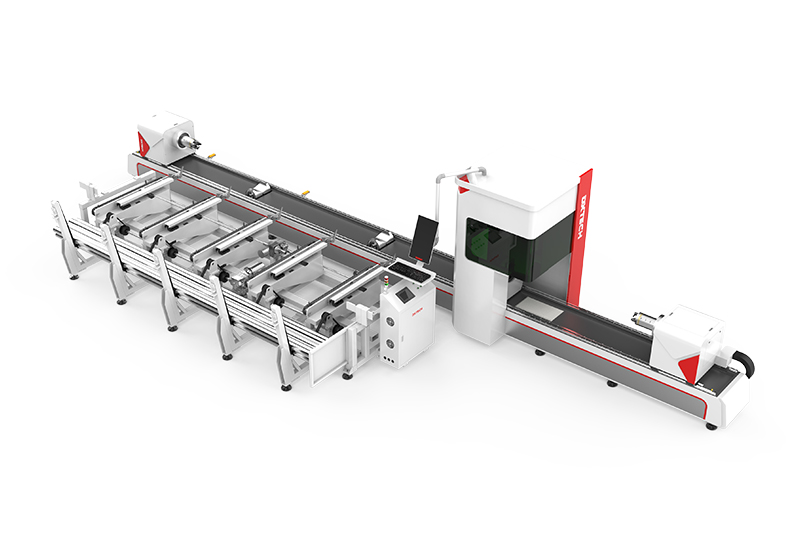

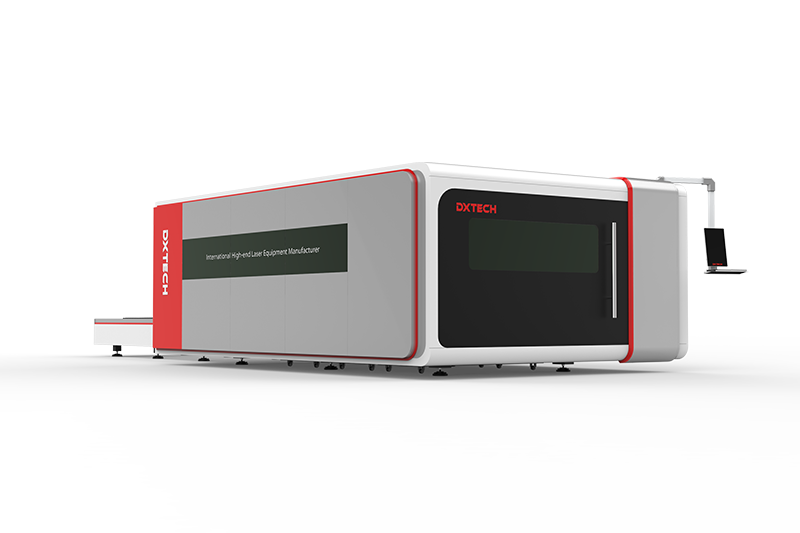

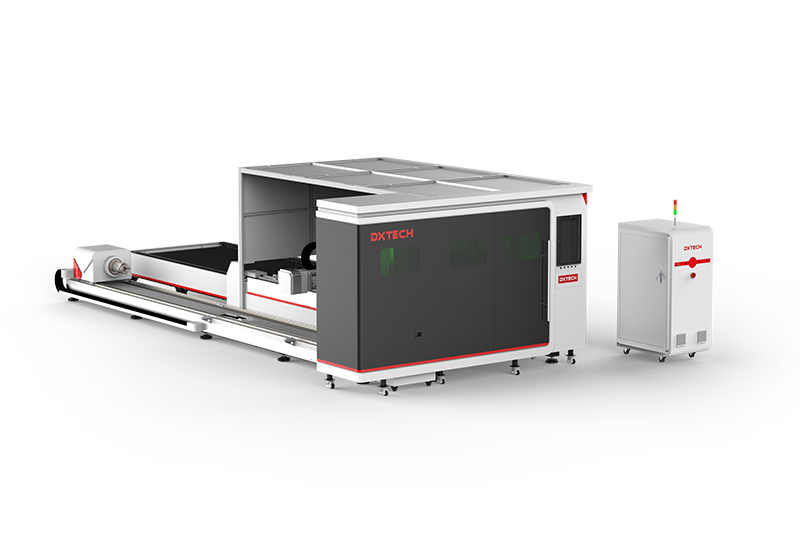

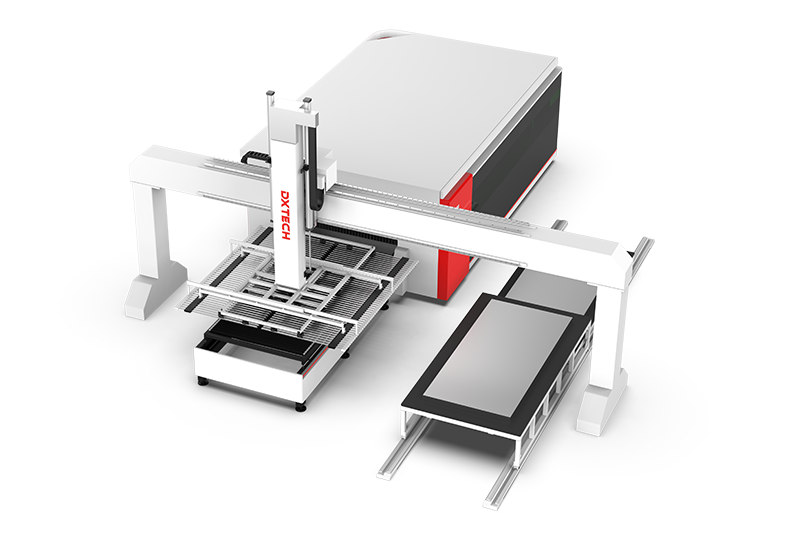

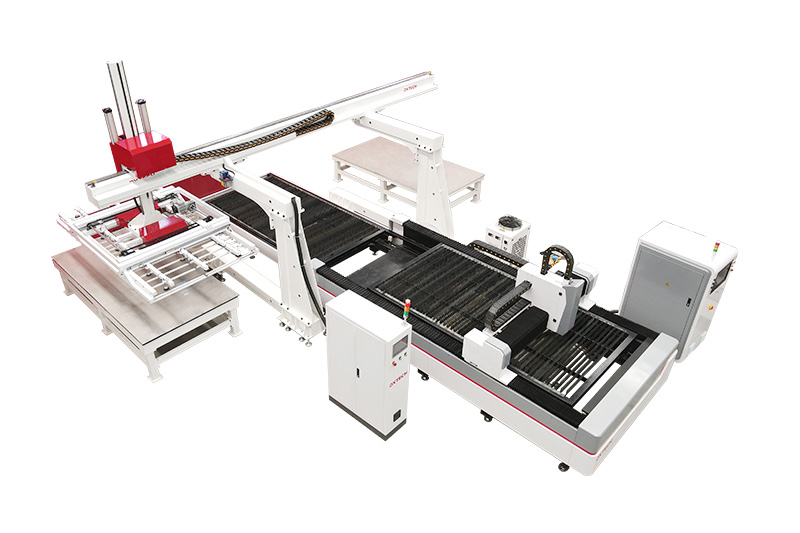

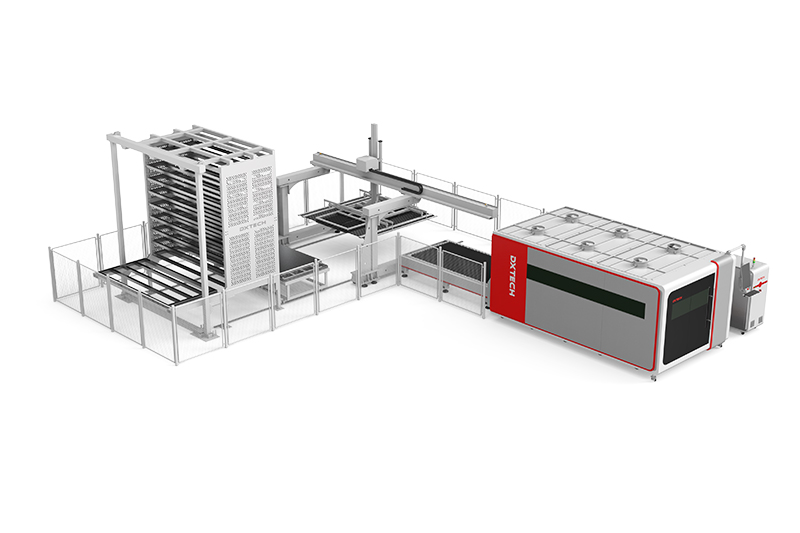

FIBER LASER CUTTING MACHINE

The fiber laser cutting machine is also named a metal laser cutter that adopting a fiber laser generator as a light source. It has many advantages, such as high processing accuracy, fast cutting speed, narrow cutting seam, minimum heat-affected zone, smooth cutting surface, and no burr.

show more

This cutting machine is mainly applicable for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, and other metal plates and pipes cutting.

And it also finds wide applications in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal external processing, kitchenware processing.

show less

Specifications

| Brand | DXTECH | ||

|---|---|---|---|

| Application | LASER CUTTING | ||

| Laser Type | Fiber Laser | ||

| Applicable Material | All kinds of metal materials: stainless steel, carbon steel, galvanized steel, aluminum, copper, and iron, etc. | ||

| Laser wave length | 1064nm | ||

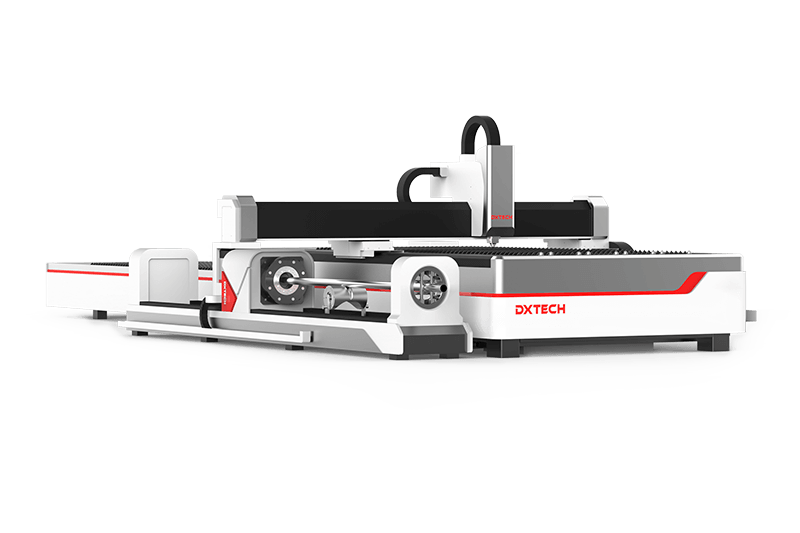

| Working Area | 1300*2500mm,1500*3000mm,1500*4000mm,2000*4000mm,2000*6000mm,2500*8000mm | ||

| Laser Power | 1000W/1500W/2000W/3000W/6000W/8000W/12000W/15000W/20000W | ||

| Repeated Positioning Accuracy | ±0.03mm | ||

| Transmission system | Gear + rails (We have standard brands, and can also produce as clients requested) |

||

| X.Y Axis Max Moving Speed | 150m/min | ||

| Max cutting speed | 1-60m/min (Depend on different metal materials and laser power and machine configuration) |

||

| Cutting Thickness (mm) | 0.5-100mm (Depends on power and materials) | ||

| Working Voltage | 220V 1ph 50hz(1KW-2KW);380V 3ph 50hz(3KW-20KW) | ||

| Gross Power | 15KW-20KW | ||

| Operating Temperature | 5-45℃ | ||

| Operating Humidity | 5-95% (Free of Condensed Water ) | ||

| Cooling Mode | Industry water chiller | ||

| Certification | ISO9001,CE, FDA, ROHS | ||

Cutting Thickness (mm)

| 1000w | Carbon Steel | 10mm |

| Stainless Steel | 5mm | |

| Aluminum | 3mm | |

| Brass | 3mm | |

| 2000W | Carbon Steel | 20mm |

| Stainless Steel | 8mm | |

| Aluminum | 6mm | |

| Brass | 5mm | |

| 3000W | Carbon Steel | 22mm |

| Stainless Steel | 10mm | |

| Aluminum | 8mm | |

| Brass | 6mm | |

| 6000W | Carbon Steel | 25mm |

| Stainless Steel | 20mm | |

| Aluminum | 16mm | |

| Brass | 12mm |

Fiber laser cutting machine uses advanced fiber laser to output high-energy and high-density laser beam. And the laser beam focus on the surface of the work piece, so that the area irradiated by the ultra-fine focus spot on the work piece is instantly melted and vaporized.

Then the spot irradiation position is moved by the numerical control mechanical system to realize automatic cutting. It is a numerical control cutting equipment with advanced fiber laser technology, numerical control technology, and precision mechanical technology.

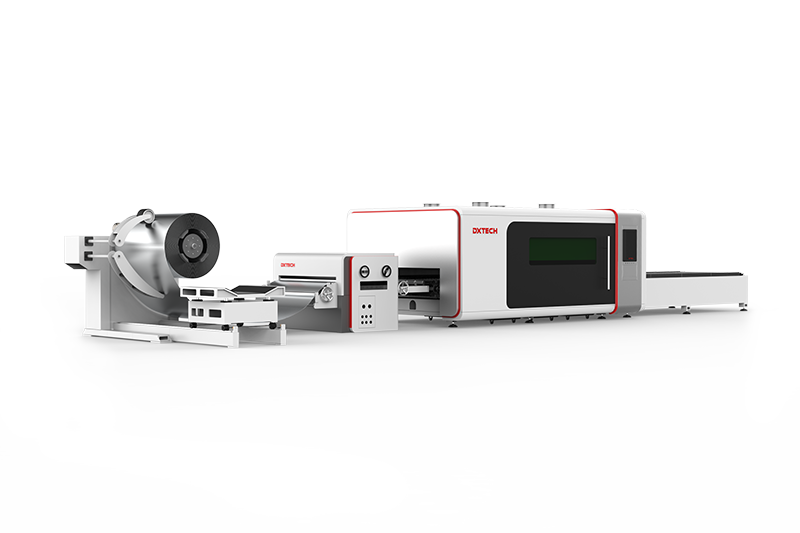

The cutting machine can mainly process metal materials, so it is also known as metal laser cutting machine. And it can cut a variety of metal plates and pipes. These materials include stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, galvanized sheet. And it also contains copper, silver, gold and other metal plates and pipes.

This type of metal laser cutting machine has a wide applicable range. It mainly includes metal sheet processing, advertising sign character production, electrical cabinet production, mechanical parts, kitchenware, automobiles, machinery, metal crafts.

And its application also contains electrical parts, eye industries, springs, circuit boards, electric kettles, medical microelectronics, hardware, knife measuring tools and other industries.

Fiber laser VS. CO2 laser

The main difference between fiber laser and CO2 laser is what kind of materials that the laser can cut. And the wavelength determines the type of materials that which of them can be applied.

As the fiber laser cutting machine can deal with various metal materials, it has become the popular and commonest used metal laser cutting machine. People prefer this kind of metal laser cutting machine because of its advanced laser cutting technology and perfect cutting result. The CNC metal cutting machine software help operators using it easily.

CO2 laser cutting machine mainly deals with various non-metal materials, like wood, acrylic, etc. Therefore it is the best choice as acrylic cutting machine and wood cutting machine. As a kind of wood or acrylic cutting machine, it will provide the perfect cutting result.

If you want to cut metal material, fiber laser is a great choice, whereas the organic materials like textiles, wood, or cardboard, choosing CO2 laser will help you a lot.

Fiber laser machine

Different types of fiber laser machine will create different cutting products. Except for the fiber laser cutting machine, there have fiber laser engraver machine, fiber laser marking machine, and fiber laser welding machine. All kinds of fiber laser machines can create delicate metal products like laser cut metal signs. With the well-performance fiber laser machines, fiber laser machine manufacturers can provide satisfying metal cutting products for their customers.

For better use of fiber laser machine, you must know the fiber laser machine basic which we will list as follows.

- High cutting precision. Positioning accuracy of the metal laser cutting machine can reach ±0.05 mm. And the repeat positioning accuracy can reach ±0.03 mm.

- Narrow slit. The laser beam is focused into a very small point to achieve a high power density at the focal point. The slit width is generally 0.10-0.20 mm.

- The cutting surface is smooth. The cutting surface has no burrs, and the surface roughness of the cut is generally within Ra6.5.

- Fast speed. The metal laser cutting machine speed can be up to 10 m/min. And its maximum positioning speed up to 30 m/min.

- No damage to the work. The laser cutting head will not contact the surface of the material to ensure that the work piece is not scratched.

- Save materials. The fiber laser cutter use computer programming. And it can realize to maximize material utilization.

- Safety and environmental protection. The cutting processing has less waste, clean, safe and pollution-free.

- Compared with the traditional laser machine, it has the advantages of no adjustment, no maintenance, high stability, etc., which reduces the cost of accessories and maintenance time.

- Abundant types of processing materials. It can process carbon steel, stainless steel, aluminum, aluminum alloy, copper, etc. In addition, it can process materials with high hardness, high brittleness and high melting point.

- High level of automation. The laser cutter adopts fully enclosed processing. I t has the features of no pollution, low noise. All these can greatly improve the task of the operator.

After a long time operation of the fiber laser machine, there will be some mechanical loss. How to achieve high-efficiency and high-quality operation, its maintenance is very critical.

- Check the steel belt frequently to ensure that the belt is in a tight state. If there is no problem during operation, it will not only affect processing, but also seriously affect the safety of operators.

- Regularly check the straightness of the track and the vertically of the machine. If abnormality is found, timely maintenance and debugging are required. Because these factors will directly affect the processing effect. Therefore, we must pay attention to it.

- Use a vacuum cleaner to suck up the dust and dirt in the machine in time. And all electrical cabinets should be closed tightly and dust proof. Ensure that the periphery of the machine and itself are clean.

- Frequently clean up components such as rail racks. The guide rails should be cleaned and lubricated frequently. Clean up the dust and other debris on the guide rail to ensure the normal operation of the equipment.

- Moreover, the rack should be wiped frequently and lubricated to ensure lubrication without debris. In this way, the machine can achieve more accurate cutting, and the quality of the cut products will be improved.

- Make sure that the power socket is in good contact and the ground wire is reliably grounded.

- Please ensure that the working voltage of the chiller is stable and normal. Because the water cooler is more sensitive to the power supply voltage. So if you really need a wider operating voltage range, you can customize it separately.

- Mismatched power frequency will cause damage to the machine. Please use 50Hz or 60Hz models according to actual conditions.

- To protect the circulating water pump, it is strictly prohibited to run without water. The water storage tank is emptied before the new laser cutting machine is packed. Please make sure that the water tank is filled with water before turning on the machine. Otherwise, the pump can easily break.

- When the water tank water level is below the green (NORMAL) range of the water level gauge, the cooling capacity of the chiller will slightly decrease. Please ensure that the water tank water level is within the green (NORMAL) range of the water level gauge. It is strictly forbidden to use a circulating pump to drain water.

- Please ensure that the air inlet and outlet channels of the chiller are smooth. The air outlet on the chiller must be at least 1250px away from the obstacle. And the side air inlet must be at least 500px away from the obstacle.

- Clean the filter of the air inlet regularly. We must remove and wash the dust-proof net regularly. Because the serious blockage of the dust-proof net will cause the chiller to malfunction.

- Please pay attention to the influence of condensed water. When the water temperature is lower than the ambient temperature and the ambient humidity is high, the circulating water pipe will produce condensed water. When the above situation occurs, it is recommended to increase the water temperature or heat the water pipe and the cooled device.

- The laser cutter is a professional industrial cutting equipment, please do not let non-professionals operate it.

The thickness of this kind of metal laser cutting machine generally does not exceed 25mm.

The fiber laser cutter is widely used in automobile manufacturing, kitchenware industry, sheet metal processing, advertising industry, machinery manufacturing, chassis cabinets, elevator manufacturing, fitness equipment and other industries.

The metal CNC laser cutting machine can provide fiber laser cutting services, such as stainless steel laser cutting, sheet metal laser cutting, and tube laser cutting. The products of cutting are trended to metal products like laser cut metal signs, or metal tube.

There are many factors that affect the accuracy of laser cutting, including the equipment itself, such as the accuracy of the mechanical system, the degree of vibration of the table, the quality of the laser beam, the influence of the auxiliary gas and the nozzle, and the attributes of the processing material.

Compressed air, nitrogen, oxygen.

There are some steps for you to choose the best CNC metal cutting machine.

First, users must first consider the materials they need to process and the scope of business needs. It includes factors such as the thickness of the material to be cut and the type of material to be cut.

Then determine the power size and table size of the equipment to be purchased. The power of cutting machines currently on the market ranges from 500W to 10000W. Manufacturers of the general size of the workbench can customize it according to customer needs.

Second, choose a fiber laser cutting machine manufacturer. After confirming the needs, we can go to the market to find out the performance of the fiber laser cutter. And we can also go to the counterparts who have bought this kind of cutting machine to have a look at the basic parameters of the machine.

Then choose several fiber laser cutting machine supplier with strong prices and preferential prices for preliminary communication and proofing. Later, we can conduct on-site inspections, machine prices, machine training, payment methods, after-sales service, etc. for more detailed discussions.

Third, choose the size of the laser power. The laser is the core component of the cutting machine. When choosing the performance of the cutting machine, the size of the laser power is very important. For example, we often cut metal sheets below 6 mm, so we can choose 500W-700W cutting machines to meet production needs. If we cut the material over 6 mm, we need to consider a more powerful machine. This is of great help to the cost control of the enterprise.

Fourth, choose the core components of the laser machine. Some important parts of the cutting machine, we also need to pay great attention when purchasing. Especially for laser generators, laser cutting heads, servo motors, guide rails, water chillers, etc., it is necessary to distinguish whether they are domestic or imported. These components directly affect the cutting speed and accuracy of the laser cutting machine.

Fifth, the quality of equipment and the stability of use are also very important metrics. Now the product development cycle is short, the update is faster and faster, the product diversity, sample trial production, mass production is more. How to complete customer orders with quality and quantity is the arduous task facing manufacturers.

So choose stable performance processing equipment is the premise and foundation. We try our best to choose brands that have a high market share, a sound after-sales service system, many after-sales service outlets, and have passed long-term market testing. You can't just buy low-quality products without after-sales service just because you are greedy for temporary low prices. This will have a huge impact on the company.

Sixth, after-sales service. The after-sales service of each fiber laser cutting machine manufacturer is very different, and the warranty period is also uneven. In terms of after-sales service, we not only provide customers with effective daily maintenance programs but also have a professional training system for machines and laser software to help customers get started as soon as possible.

If you are seeking for the cheap or affordable fibber laser cutter, creating cooperation with fiber laser cutting machine manufacturers is the best choice. Reliable fiber laser cutting machine manufacturers will help you to save costs and complete buying guide for you. On the other hand, the fiber laser cutting machine supplier you cooperating must have a close after-service and efficient delivery.

- Reliable Fiber Laser Cutting Machine Manufacturers

- High-quality Fiber Laser Cutting Machine

A reliable fiber laser cutting machine manufacturer can provide complete instruction of this CNC laser cutting machine, and work closely with you with full preparation to solute any problem that you might meet when you use the CNC laser cutting machine.

There are some factors you must take when you select your fiber laser cutting machine manufacturers.

- Advanced laser technology

- Professional research & service team

- On-time communication