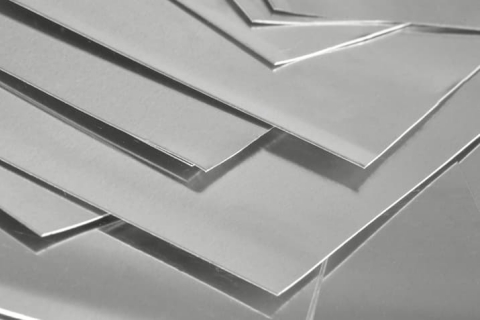

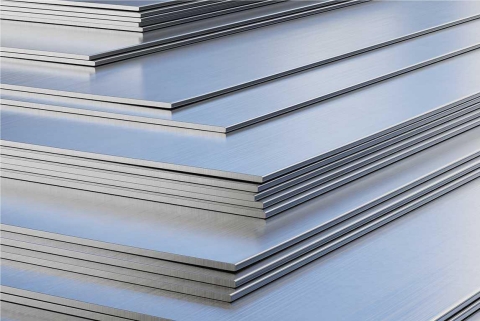

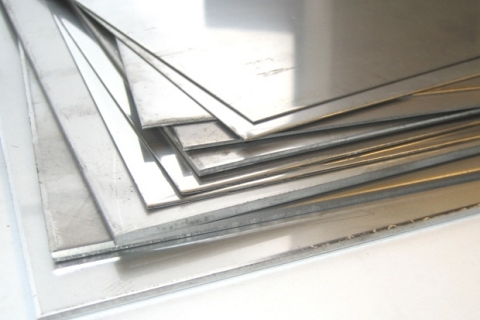

Plate Cutting Shears Sample

Applicable to furniture industry, automobile industry, railway industry, construction industry, home appliance industry, gardening industry, mold industry, bathroom industry, fitness equipment manufacturing industry, aircraft manufacturing, light industry, shipbuilding industry, elevator manufacturing industry, etc.

We provide free proofing, welcome to consult.

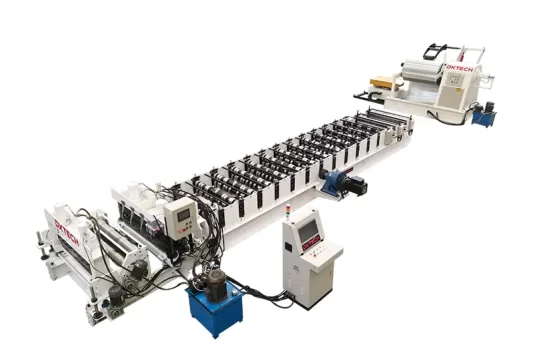

1.The main features of the machine

Shearing Machine streamlined looking,Monoblock,The frame of this machine tool is welded construction with steel plate,and stress is eliminated by vibration. As a result, this forging machine features high strength, stable performance, easy operation and convenient maintenance.

2.The main components and structure of the machine

2.1. All-steel structure design and outloo, beautiful appearance and reliable structure.

2.2. Using UG (finite element) analysis method, computer-aided optimization design.

2.3. The overall steel plate welding structure has good strength, rigidity and vibration resistance. The two cylinders are fixed on the left and right columns. There is an auxiliary knife seat on the working table, which is convenient for micro-adjustment of the blade. There is also a feeding roller on the working table. , easy to operate.

2.4. Use vibration aging technology to eliminate internal stress. 5. The overall frame is derusted by sandblasting and sprayed with antirust paint.

3.Main technical parameters

| Model | DX-PB-4×2500 | DX-PB-6×3200 | DX-PB-8×2500 | DX-PB-10×2500 | DX-PB-16×2500 | |

| The cutting maximum plate thickness | 4mm | 6mm | 8mm | 10mm | 16mm | |

| The cutting maximum board width | 2500mm | 3200mm | 2500mm | 2500mm | 2500mm | |

| Sheared sheet strength | 450 pressure | 450 pressure | 450 pressure | 450 pressure | 450 pressure | |

| Cutting angle | 1’30 ° | 0.5° | 0.5° | 0.5° | 0.5° | |

| Maximum distance of backgauge | 600mm | 500mm (or customized 700mm) | 600mm | 600mm | 800mm | |

| Number of trips | 12 times/min | 10 times/min | 12 times/min | 10 times/min | 9 times/min | |

| CNC system | ESTUN E21S | ESTUN E21S | ESTUN E21S | ESTUN E21S | ESTUN E21S | |

| Main motor | Model | Y132M-4 | Y132M-4 | Y132M-4 | Y132M-4 | Y132M-4 |

| Power | 5.5kw | 7.5kw | 11kw | 11kw | 18.5kw | |

| Spees | 1440rpm | 1440rpm | 1440rpm | 1440rpm | 1440rpm | |

| Back gauge motor | Model | YS8048 B3 | YS8048 B3 | YS8048 B3 | YS8048 B3 | YS8048 B3 |

| Power | 0.37kw | 0.37kw | 0.37kw | 0.37kw | 0.37kw | |

| Spees | 660rpm | 660rpm | 660rpm | 660rpm | 660rpm | |

| Oil pump | Model | NBZ4-G20F | NBZ4-G20F | NBZ4-G25F | NBZ4-G25F | NBZ4-G50F |

| flow | 20ml/r | 20ml/r | 20ml/r | 20ml/r | 20ml/r | |

| Pressure | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

4.Working environment and conditions of use

This machine is suitable for any material preparation workshop, and its conditions are:

- Ambient temperature: -10~+40℃ (the temperature of the fuel tank shall not be lower than +10℃)

- Relative humidity: ≤80% (+25℃)

- Power source: 3phase 380V±10% 50Hz(or customized)

This machine has no “three wastes” discharged, and the noise limit meets the requirements of JB9969-1999.

5.Installation, test, acceptance and after service

5.1.Seller should inform the buyer to inspect the machine in our factory after the machine is finished.

5.2.Seller should supply corresponding files and foundation drawings in 7 days after confirming the order.

5.3.If buyer needs the installation, test by seller, then the charges in China will be taken by seller. And charges out of China, such as tickets, and hotels, should be taken by the buyer.

Reviews

There are no reviews yet.