Application of Metal Laser Cutting Machine & Laser Engraving Machine in Fitness Industry

The focus of the state on sports fitness and the creation of personal health principles. Square exercise equipment and home fitness equipment have steadily grown and demand has increased. As one of the most common cutting methods, CNC laser cutting has now become commonly used in the manufacturing of fitness equipment. Compared to the conventional tube cutting process, the CNC laser cutting system has a high processing versatility and can be tailored for various tubes. Quality and performance have both vastly increased relative to the conventional method. The rapid rise in demand for sports and exercise has also fuelled the demand for more fitness equipment in terms of quantity and quality. Due to the vast volume of pipe manufacturing in the exercise equipment industry, such as rotating bikes, motorcycles, sit-ups, children’s scooters, outdoor workout equipment and other items, all of these include a huge range of pipe pieces, pipe cutting and punching methods.

Applicable Advantages for Fitness Industry

- Flexibility: It can cut any outline that has been programmed on the stainless steel tubing, and the laser can be cut in any direction. The form to be processed can be modified easily and flexibly by computer programming.

- Precision: At the same time, as shown above, various materials can experience minor expansion and deformation during processing.

- High Efficient: The laser pipe cutting machine has centralized operation, flexible processing, loading and unloading, and the clamping is convenient and fast.

Laser Cutting Fitness Supplies

By raising people’s living conditions, while paying more attention to fitness, people are increasingly paying attention to their physical attractiveness. It is precisely this desire that has propelled the growth of the fitness industry, and the ongoing expansion of the fitness squad has also created good market opportunities for fitness equipment manufacturers. If exercise equipment producers want to be invincible in this current scenario, they must step up technical creativity, aim to increase product efficiency and enhance autonomous research and development capability. In recent years, CNC laser cutting technique has been used in a mature way and has increasingly been applied to the manufacturing of exercise devices. Compared to conventional metal laser cutting methods, laser cutting devices are able to cut and minimize work pieces of higher size. CNC Laser cutting machine has a high degree of flexibility, quick cutting speed, high output performance and short life cycle.

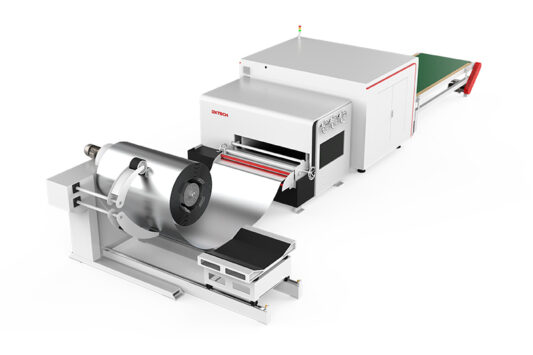

Product Display

Machines like CNC metal cutting are also made with the help of metal laser cutter for precise and accuracy which people demand from any quality gym is only possible with the help of metal laser cutting machine only.

Whereas complex machines like multipurpose weight machines also required a depth of precison in its manufacturing and could only be done with the help of CNC metal cutting only.

Whereas the several precised pipes on simple row machines also need a precise and accurate cutting so equal weight distribution could be applied on the machine and without precision gym is useable.

Laser Cutting Process

The CNC metal cutting for plate and tube, produced and manufactured by the metal laser cutter machine manufacturer for the sports and fitness equipment industry, is capable of cutting different shapes of pipes and is capable of processing some complicated curve graphics on the pipe surface which are not limited to the complexity of the graphics. The pipe portion does not need secondary processing and can be directly welded, which dramatically shortens the manufacturing time and provides infinite value for the brand.

Fitness equipment goods use a wide number of pipe sections, so that the pipe is recycled more often when producing fitness equipment. CNC metal cutting and punching techniques are widely used in industrial engineering. Traditional metal laser cutter techniques can no longer be suited to modern industrial needs, so the use of high-efficiency high-precision metal laser cutter is a general practice.

There are several Fitness equipment goods use a wide number of pipe sections, so that the pipe is recycled more often when producing fitness equipment. Tube cutting and punching techniques are widely used in industrial engineering. Traditional metal laser cutter techniques can no longer be suited to modern industrial needs, so the use of high-efficiency high-precision metal laser cutter machines is a general practice. The graphics and the length of the pipe are not constrained. In the case of secondary manufacturing, welding can be done directly, dramatically shortening the development time, and the application of laser cutting machine equipment can produce more profit for the business.