Laser cutting technology is widely used in various industries for cutting and engraving different materials now. And there are different models of industrial laser cutter for different needs. What can they do respectively? Moreover, how to choose the best industrial laser cutter to meet daily processing demands? The following discusses the industrial laser cutter in detail and gives suggestions for different uses.

According to the laser source and the processing materials, the industrial laser cutter generally has two types. One is the fiber laser cutting machine, and the other industrial laser cutter is the CO2 laser cutting machine. The fiber laser cutting machine is for cutting metal materials, for example, carbon steel, stainless steel, and galvanized steel. While the CO2 laser cutting machine mainly cuts and engraves almost all non-metallic materials, such as wood, acrylic, fabric, paper, and leather.

Fiber laser cutting machine

This fiber laser cutting machine refers to the steel laser cutting machine that uses fiber laser source to cut metals. It is a kind of industrial laser cutter specially for metal processing. Sometimes, people call it the laser metal cutting machine.

Working principle

The laser metal cutting machine uses the laser beam emitted from the laser generator to focus into a high-power density laser beam irradiation condition through the optical path system. And then, the fiber laser heat is absorbed by the metal material, and the work-piece temperature rises sharply. After reaching the melting point, the metal material begins to melt and vaporize. In addition, the high-pressure gas coaxial with the beam directly blows off the molten metal. And the machine cut through the metal material and form a very small hole. Along with the movement of the laser head, numerous small holes appear and connect to be the outline of cutting.

The above video shows the fiber laser cutting machine is cutting steel plates quickly.

Because the frequency of fiber laser cutting is very high, the connection of each small hole is very smooth. And the metal product after fiber laser cutting has a high degree of finish. This shows that the laser cutting process is essentially different from the machining of the machine tool.

Working features

- Excellent beam quality

The fiber laser metal cutting machine has smaller focusing spot, finer cutting lines, higher work efficiency, and better cutting quality.

- High cutting speed

The cutting speed of steel laser cutting machine is 2 times that of the same power CO2 laser cutting machine.

- Extremely high stability

The fiber laser has a stable performance. And the service life of key components can reach 100,000 hours. As an industrial laser cutter, it can complete mass production.

- Very high electro-optical conversion efficiency

The fiber laser metal cutting machine has a high photoelectric conversion efficiency, reaching about 30%. It is energy-saving and environmentally friendly.

- Very low use and maintenance costs

With low power consumption, the fiber laser cutter has no laser working gas; optical fiber transmission. And with no need for reflective lenses, this industrial laser cutter with the fiber source saves lots of maintenance costs.

- Convenient operation and maintenance

Because of the optical fiber transmission, the steel laser cutting machine is no need to adjust the optical path.

Fiber laser cutting machine has high cutting precision, cutting precision parts, and fine cutting of various crafts and metals. We can see from the video at left that the cutting speed is quite fast. And laser cut steel has smooth cutting edges. The heat-affected area is small, and the laser cutting performance is stable. It is not easy to have deformation by using a fiber steel laser cutting machine. And the cutting seam is smooth and beautiful, without further grinding and polishing.

Comparing to the CNC punching machine, the industrial laser cutter with fiber laser can complete various complex cutting on metal.

Three Most Popular Models of fiber laser cutting machine

In the practical laser cutting application, the users often have different specific processing demands. Some beginners may want to buy an economical industrial laser cutter machine. And some users may require a higher automation level, and also may ask for the additional protective devices.

At below, we introduce 3 types of fiber laser cutting machines that can basically meet the needs of different users.

Economical Fiber Laser Cutting Machine for Metal

This economical fiber laser cutting machine has high cost performance, low consumption and low cost, simple maintenance, and convenient operation. And this industrial laser cutter can cut and process various metal materials, for example, stainless steel, carbon steel, and galvanized sheet. It is the industrial laser cutter that can complete basic metal cutting demands perfectly.

Please click the link below to get more information.

Exchange Platform Fiber Laser Cutting Machine

As the name shows, this exchange platform fiber laser metal cutting machine has two worktables. Two processing working tables can realize the load and unload function at the same time. They not only saves time for manual loading and unloading but also improves production efficiency, and are very convenient.

Besides, the core electrical and driving parts of such steel laser cutting machine are of the internationally famous brands. And it guarantees a long service life of this machine. With the characteristics of fast processing speed and high production efficiency, this industrial laser cutter is always popular among users.

Protective Fiber Laser Cutting Machine for Metal

This protective laser metal cutting machine adopts a fully enclosed laser protective cover. It combines both functions of being safe and visible. This steel laser cutting machine not only ensure the safety of the operator but also be more environmentally friendly. And the professional CNC cutting system ensures high-speed and stable operation of this machine.

Applications of fiber industrial laser cutter machine

The laser metal cutting machine is applicable in sheet metal processing, electrical appliances, subway accessories, and automobile machinery. And there are many users in the advertising, engineering machinery and kitchenware processing, tool processing, and household appliances processing industries.

Laser cut metal signs in advertising

Laser cut metal letters and signs for advertising and decoration are very common in our life. Stainless steel, titanium, and copper are usually suitable for making laser cutting metal signs.

Playing a leading role in advertising processing, the laser cut metal signs have the most direct publicity effect. And they also present the image of the store and transmitting brand information.

Laser cut metal letters can also be matched with lights of different colors, making them eye-catching at night. The light shines with the outline of the laser cut metal. And these laser cut metal signboards also bring new vitality to the advertising industry.

The laser cut metal signs and letters have smooth three-dimensional edges with exquisite appearance. Of course, it is easy to process the custom metal signs by using a fiber industrial laser cutter.

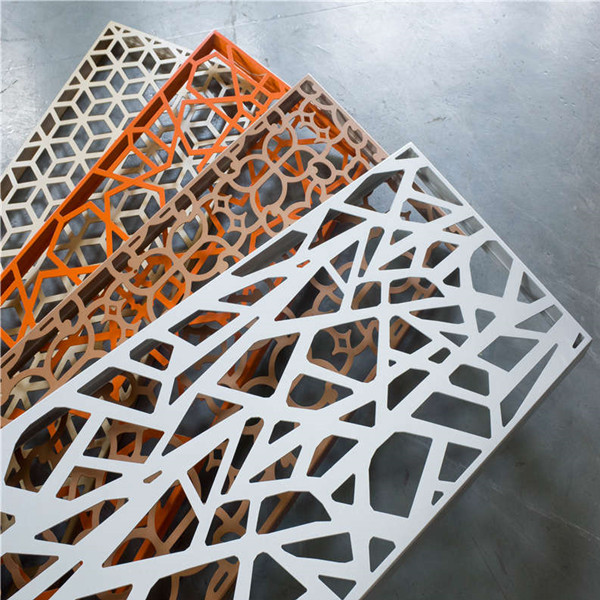

Laser cut aluminum curtain wall

The laser cut aluminum curtain wall is widely used in office buildings, shopping malls, stations, and many other buildings. The curtain wall of laser cut aluminum is light in weight, has high strength and stable functions. It can prolong the life of the building and enhance the sound insulation effect.

And the curtain wall made of laser cut aluminum can also give people a stronger visual and psychological impact. Moreover, it can relieve the depression caused by the closed space, and broaden the field of vision and the perception of space. In addition, laser cut aluminum can be completely recyclable, which is a good material in building decoration.

Furthermore, the cutting patterns of laser cut aluminum for curtain walls can be processed according to customers’ specific requirements. Therefore, the users can cut and drill holes of various shapes on aluminum materials by using a laser metal cutting machine.

In short, the laser cut aluminum curtain walls and screens meet customers’ individual pursuit of decoration very well.

Laser cut steel tube for medical instruments

The steel tubes for medical instruments have higher requirements for processing technology and equipment. Because they must be of high accuracy, stability, safety, and purity. Therefore, more and more medical industry manufacturers are beginning to realize the advantages of laser cut steel. And the laser cut steel for medical use has high precision and high-quality cutting edges.

As the laser beam is thin, the seam of the steel medical instrument after laser cut steel processing is very narrow. And thus, the small cutting seams guarantee the high cutting precision of laser cut steel tubes.

The application of laser cut steel has greatly improved the manufacturing quality and sales of medical equipment.

CO2 laser cutting machine

CO2 laser cutting machine is a kind of industrial laser cutter using CO2 laser technology with a wide application range. The main gas filled in the laser tube of this laser cutting machine is CO2. And it is a kind of industrial laser cutter specially for non-metal cutting and engraving.

Working principle

When the CO2 laser cutting machine starts working, the laser power supply drives the CO2 laser tube to emit the laser. Through the reflection of several optical lenses, the laser is transmitted to the laser head. And then, the focusing lens installed on the laser head condenses the laser into one laser spot. Such a laser spot can reach a very high temperature. Thereby the wood, acrylic, or other non-metal materials are sublimated into gas instantly and sucked away by the draft fan. In this way, this CO2 industrial laser cutter achieves the purpose of cutting.

Working features

- Good cutting effect

For example, the cutting surface of the acrylic material does not need further polishing. In addition, it is very smooth, and there is no jagged pattern.

- Wide range of processing

The CO2 industrial laser cutter can cut and engrave almost all non-metallic materials. For example, plastic, wood, PVC, leather, fabric, and organic glass are common materials.

- CO2 laser tube has a long service life

A good CO2 laser tube has stable performance and long service life. With proper maintenance, the service life of a high-quality CO2 laser tube can reach up to 20,000 or 30,000 hours.

- Fast cutting speed

This industrial laser cutter cuts non-metallic plates quickly and is often used to cut 3mm thick acrylic and other plates. The left video shows a CO2 laser cutter machine cutting mdf board precisely and efficiently.

Generally, the advantages of using a CO2 industrial laser cutter to cut non-metallic materials include fast speed, high precision, and accurate positioning.

Popular Models of CO2 laser cutting machine

According to different processing needs of customers, we recommend the three most popular CO2 laser cutting machines as follows.

Desktop CO2 Industrial Laser Cutter

This desktop CO2 industrial laser cutter machine has a smaller size and is easy for moving to different working places. Moreover, it also adopts an integrated frame structure design to make the operation more stable. According to the different processing objects, the users can upgrade the machine and equip it with different accessories.

Therefore, it can meet the diverse processing needs of users. For example, the working table of this desktop industrial laser cutter can choose the blade table or the honeycomb table. According to the nature of the processing material, it can install the soft material adsorption device to fix the work-piece. Therefore, such an industrial flexible laser cutter also meets individual processing requirements.

For more details please click the link at below.

CO2 Laser Cutting and Engraving Machine

This is a classic CO2 laser engraving machine, which has the advantages of low cost, integration degree, wide application range. This machine also has an open processing platform. So that the users can directly monitor the cutting process and make timely adjustments.

And this industrial laser cutter engraver adopts non-contact processing to ensure the processing quality of the work-piece. The openwork platform facilitates the loading and unloading of the materials. Furthermore, it can also cooperate with the assembly line to meet the processing of large-format materials.

Therefore, this industrial laser cutter engraver is not only suitable for large-scale processing industries such as clothing, machinery, and advertising. Furthermore, it meets the needs of small industries such as the model industry, crafts making, and wood processing.

CO2 Laser Engraving Machine with Double Heads

This CO2 cutting and engraving machine has two laser heads. And these two laser heads can work at the same time. Therefore, the users can effectively shorten the production time, and effectively improves the processing efficiency. In general, this type of CO2 industrial laser cutter is applicable for mass production of cutting wood, acrylics, plastics, paper, and fabrics.

Applications of CO2 industrial laser cutter machine

The popular applications of CO2 industrial laser cutter include wood processing, advertising, crafts, clothing, printing, and packaging industries. Of course, many users also use this machine to produce building decorations, paper products, and foam molds. As there are countless examples of the application of CO2 industrial laser cutter, we choose three typical ones for discussion.

Laser cut acrylic jewelry

The laser cut acrylic sheet and laser cut polypropylene resin are low-carbon, environmentally friendly, and non-toxic, and odorless. Actually, they are new healthy and fashionable materials in accessories and crafts processing industries.

At present, the market prospect of using laser cutting acrylic to make craft gifts is getting better and better. Moreover, laser cutting processing has won people’s recognition due to its high-speed and processing advantages. For example, laser cut acrylic jewelry can be used for a long time, and will not change color.

According to the computer design drawings, the CO2 industrial laser cutter cuts out the patterns and dimensions as required. Laser cut acrylic earrings are a kind of modern and fashionable laser cut jewelry. Besides, they are also both cheap and delicate.

Most wholesale services for laser cut acrylic jewelry can provide customers with high-quality products at reasonable prices.

The laser cut acrylic jewelry is stylish and full of a sense of fashion. And the same is the laser cut acrylic storage box, allowing the jewelry to shine even in the box. The storage box made of laser cut acrylic sheet has a better light transmission and crystal transparency. Therefore, daily necessities are stored in an orderly and neat manner.

The users can quickly find the stored items, which saves space and time. And it is very suitable for homes, hotels, office places. And we can also use CO2 laser cutting technology to engrave a personality logo on acrylic.

The laser cut acrylic has smooth edges and corners, no burrs, and no danger to hurt hands. Moreover, the non-contact laser processing method will not damage the acrylic material, which is beautiful and practical. Thus, it is also a very popular material in advertising processing.

Laser cut wood lamp

Laser cut wood is also a very popular material in home decoration, advertising, wood processing and many other industries. Lamps play an important role in modern home life. Mostly, it can create atmosphere and decorate the space. Laser cut wood lamps and lanterns can especially add splendor to the living space. The role of laser cut wood lamps is not only limited to lighting.

The simple shape gives the lamp a unique appearance, simple but not simplistic. When the light is on, the laser cut wood lampshade will have a sense of artworks and modern feeling.

At the same time, the subtle shadow of the lampshade creates an elegant atmosphere for the room. The laser cut wood lamp brings a soft feeling to the room, and also reflects the elegant and stable temperament.

In the left picture, this lampshade has intricate details and lighting techniques. The laser cut wood lampshade shows the effect of light and shadow interaction. The lamplight irradiates from the hollow graphics to create an exquisite and beautiful lampshade.

According to the needs of industry development, many designers apply laser technology to artistic household design. The laser cut wood lamp for the living space is just like the icing on the cake. And it brings users a double enjoyment of body and mind.

Laser cut paper in packaging

The laser cut paper is mostly used in packaging, such as candies, cakes, wine, and bottle labels. In many cases, when choosing products, more people prefer to choose the packaging that looks unique and high-end. Therefore, the laser cut paper packaging with exquisite patterns and creative styles is always welcomed by customers.

The laser cut paper packaging, through laser hollowing, has a strong 3D effect, flat incisions, and owns novel styles. Because of non-contact processing of laser, the cutting graphics of the laser cut paper are clear, non-yellowing and no deformation.

Moreover, the production cost is low and the efficiency is high. The laser cut paper cutting machine leads the development trend of paper packaging production. Absolutely, the materials of packaging could not only be laser cut paper, and also be laser cut fabric, plastic and wood.

Conclusion

In general, the above mainly introduces two major industrial laser cutter machines: fiber laser cutting machine and CO2 laser cutting machine. When purchasing an industrial laser cutter, the users should choose the machine according to the processed material at first. If the users mainly cut metal materials, the fiber laser machine is the best choice. And if they mostly process non-metallic materials, choose a CO2 laser machine. In addition, different materials or the same material with different thicknesses require different laser power. And the users must choose the appropriate laser power according to specific materials and thicknesses.

Whether it is a fiber laser machine or a CO2 laser machine, the use of an industrial laser cutter can improve the efficiency of engraving and meet the needs of industrial processing. Non-contact processing of industrial laser cutter ensures that the cutting surface is also relatively smooth, free of burrs, and very small or no deformation. Because the industrial laser cutter has so many advantages, it is widely used in various industries and fields in practical applications.

The industrial laser cutter is gradually replacing traditional cutting machines and technology, becoming the main industrial cutting equipment. At the same time, it is also optimal to meet the requirement of energy-saving processing and environmental protection cutting.