CNC laser cutting machine price discourages many people. But Why? As we all know, the laser cutting machine is an advanced machine for cutting metal or non-metal materials. It has high processing precision, fast cutting speed, and a wide application range. It is one of the most ideal cutting machines for processing various materials. There are still many questions about CNC laser cutting machines. Why is the CNC laser cutting machine price so high? What is the difference in the price of different types of laser cutting machines? What factors will affect the CNC laser cutting machine price? How can I buy a cost-effective laser cutting machine? If you also have such confusion, then this article will take you to find the answers to these questions.

I.Different CNC Laser Cutting Machine price

There are many types and functions of laser cutting machines. According to their types, they can be roughly divided into two categories: fiber laser cutting machine and CO2 laser cutting machine. According to the function, it can be divided into metal laser cutting machines and exchange platform laser cutting machines. The configuration, size, and power of these laser cutting machines are different. And the cutting materials are also different. So, the CNC laser cutting machine prices are also very different. Next, I will select a few of the more typical CNC laser cutting machines for a simple comparative analysis for your reference.

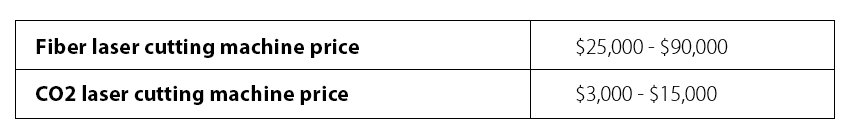

1.Different types of laser cutting machines

At present, there are two main types of laser cutting machines. They are fiber laser cutting machines and CO2 laser cutting machines. CNC fiber laser cutting machine price is higher because it is used to cut most metals and its power is strong. Its power ranges from a few hundred watts to tens of thousands of watts. However, the CO2 laser cutting machine is mainly used to cut non-metals. Its power is relatively small, usually between tens of watts to hundreds of watts. The size of the laser power directly reflects the cutting ability of the machine, thus affecting the price of the machine. Therefore, the CNC fiber laser cutting machine price is generally higher than that of the CO2 laser cutting machine.

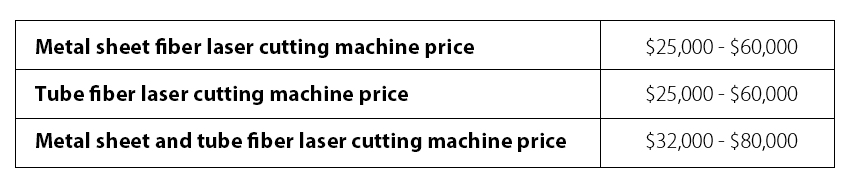

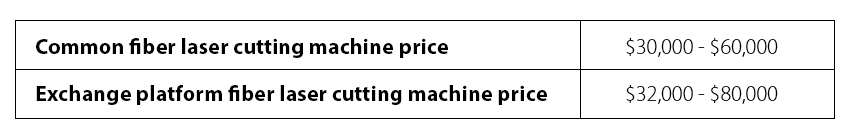

2.Laser cutting machine with different functions

According to the different metal materials to be cut, there are different CNC metal cutting machines for sale. It can be divided into metal sheet fiber laser cutting machines, tube fiber laser cutting machines, and metal sheet and tube fiber laser cutting machines. Therefore, CNC metal cutting machine price will have some differences because of such various types. For example, metal sheet and tube fiber laser cutting machines have complete functions. It can process metal plates and three-dimensional processing of metal tubes. Its price is certainly more expensive than metal sheet fiber laser cutting machines or tube fiber laser cutting machines.

The exchange platform fiber laser cutting machine has two working tables, one more working table than a single table laser cutting machine. Thus, the price of the exchange platform fiber laser cutting machine will be much higher. The exchange platform laser cutting machine is convenient for users to quickly load and unload materials. And it is also beneficial to industrial enterprises that process metal in batches. Then it can greatly improve the overall industrial production efficiency.

II.Why is the CNC Laser Cutting Machine Price Expensive?

From the above three groups of comparative analysis, it is not difficult to see that the CNC laser cutting machine price is basically in the tens of thousands of dollars. While the average price of ordinary cutting machines may be only a few thousand dollars. So why is it so expensive?

First of all, the quality of the part configuration determines the CNC laser cutting machine price and processing performance. The reason why the cost of CNC laser cutting machine is so expensive is that the cost of its parts and configuration is high. For example, to achieve high accuracy of laser cutting, a stable laser source, high-precision guide rails, strong beams, and good motors and drives are required. To ensure the stable operation of these parts to achieve high speed and cutting precise, it is necessary for CNC laser cutting machine manufacturers to cooperate with world-class CNC parts suppliers to introduce their high-quality parts to manufacture laser cutting machines.

Secondly, the CNC laser cutting machine has very prominent advantages. The CNC laser cutting machine can not only automatically typesetting, but also process any design. At the same time, it has a fast laser cutting speed and smooth incision. It seems that it generally does not require subsequent processing. It also has small cutting heat affected zone and plate deformation. Its processing accuracy is high. And the surface of the material is not damaged. These high-intelligence features are also the result of high-cost optimization.

In summary, the high specification configuration and outstanding advantages of the laser cutting machine enable it to meet the higher processing needs of the factory. And its market prospects are very broad, so the cost of CNC laser cutting machine will be more expensive compared to ordinary cutting machines.

III.What Factors will Affect the CNC Laser Cutting Machine Price?

Many factors affect the CNC laser cutter price. The most important factor is the configuration of the machine’s parts. In addition, the CNC laser cutting machine price is also affected by other external factors, such as the manufacturer, the degree of newness, transportation costs, and so on.

1.Components

1.1 Motor and drive

The motor and drive are the equipment that drives the movement of the laser head. Stepper motors and drives are relatively cheap, and servo motors and drives are slightly more expensive. Generally speaking, the motors and drives used in reliable laser cutting machines are produced by the world-renowned motor and drive manufacturers. Therefore, users should not blindly pursue low prices when choosing these two parts. They can consider various aspects according to their requirements and then choose a suitable motor and drive.

1.2 The control system

The control system can be described as the brain of the CNC laser cutting machine. Some control systems are relatively simple. For instance, the control of the machine can be achieved through the buttons on the hand-held controller. This kind of controller generally has a relatively low price. While some high-end control systems are equipped with a display screen, which allows users to adjust cutting parameters more intuitively. At the same time, they also have many other functions, such as breakpoint compensation, autofocus, etc., which are more convenient for users to use. Of course, this also means that the overall CNC laser cutter price will be higher.

1.3 The bed and beam

The impact of the bed and beam on CNC laser cutting machine price includes two aspects. First, the size of the work surface will directly affect the CNC laser cutting machine price. The larger the machine processing area, the larger the bed and beam, and the higher the price. In addition, the quality and material of the bed and beam will also affect the CNC laser cutting machine price.

1.4 Protective cover

Some countries may require high environmental protection. For this, we give them priority to purchase CNC laser cutting machines with protective covers. Though this kind of machine is more expensive than an open laser cutting machine, it is more environmentally friendly and safer.

2.Manufacturer

In addition to the reasons for the machine itself, the CNC laser cutting machine price is also affected by the manufacturer. Some CNC laser cutting machine manufacturers have large scale, complete production lines, and excellent work teams. They not only have various types of CNC laser cutting machines for sale but also can complete the production of laser cutting machines with quality and quantity. While some small-scale laser machine manufacturers will deliberately lower the price, to make their laser cutting machines have a price advantage. That means it has to make sacrifices in the machine configuration. They will choose some unqualified parts for assembly. Therefore, when we are choosing CNC laser cutting machine manufacturers, we should investigate his scale as well as assembly standards. Besides, we should also choose those who have long-term cooperation with the world’s first-class CNC component manufacturers.

3.Extra Cost

In addition, the CNC laser cutting machine price also includes some extra fees, such as transportation fees, packaging fees, taxes, and other costs. If the buyer chooses an imported CNC laser cutting machine, then he needs to bear the transportation fees and taxes of the machine. At the same time, different laser cutting machines require different packaging materials. And maybe some buyers will also make some specific requirements for packaging. So the packaging fees will also be different. Finally, if the buyer wants the CNC laser cutting machine manufacturers to assign a technician to give some guidance, this service is usually charged. Therefore, when purchasing a machine, users should know clearly that whether the CNC laser cutting machine price includes other service fees.

4.condition

The CNC laser cutting machine price, especially the CNC fiber laser cutting machine price, is relatively high. In order to save costs, some users may choose to buy second-hand laser cutting machines at much lower prices. There will inevitably be wear and tear after use for a while. Then it will greatly reduce the processing accuracy. Moreover, many machines have exceeded the warranty period. Once the parts break down, users need to spend a lot of money to repair and replace them. When the user’s funds are tight, cheap second-hand machines may be a viable option. However, for users who are not familiar with laser cutting machines or have high processing requirements, buying a new machine is the best choice.

IV.How to buy a cost-effective laser cutting machine?

Nowadays, there are too many distinguishable CNC laser cutting machines for sale, how do choose a suitable one? If you want to buy a cost-effective laser cutting machine, you must first cooperate with trusted CNC laser cutting machine manufacturers, and then choose the appropriate configuration according to the processing needs and capital budget.

DXTECH has rich experience in the production of laser cutting machines. It also has professional technical personnel, which can provide customers with timely technical guidance. In the selection of machine parts, DXTECH has reached long-term cooperation with many internationally renowned CNC parts manufacturers (such as German Siemens, Schneider, Shimpo, Taiwan HIWAN, etc.). Good customer experience is our eternal purpose. We are committed to providing customers with high-quality and high-standard laser cutting machines. In addition, DXTECH can also customize machines according to customer needs to meet customer processing needs. The following 4 machines are cost-effective and very popular laser cutting machines. If you are looking for the right machine, you can take a look at the following.

1.Economical Fiber Laser Cutting Machine for Metal

DXTECH has several CNC metal cutting machines for sale. Some of the CNC metal cutting machine price is high, some are relatively cheap. This metal sheet fiber laser cutting machine is one of DXTECH’s best-selling models. It is manufactured for sheet metal processing. The laser power can be customized according to the type and thickness of the metal plate that customers need to process. Its open design can process large-size sheet metal. In addition, the machine has a strong load-bearing capacity, stable operation, and high machining accuracy. It can process stainless steel plate, galvanized plate, aluminum plate, brass plate, and other plates.

2.Multifunctional Metal Sheet and Tube Fiber Laser Cutting Machine

Some users need to process metal sheets and metal tubes at the same time, especially those engaged in processing sports equipment, medical equipment, metal cabinets, etc. Buying a sheet metal laser cutting machine and a metal pipe cutting machine will cost a lot of budgets. And this metal sheet and tube fiber laser cutting machine can provide you with a more cost-effective solution.

3.The Most Popular CO2 Laser Engraving Machine

The above two machines are generally used for industrial metal cutting. If you want to process acrylic, MDF, fabric, and other non-metals to help you complete some design hobbies, then this household CO2 laser cutting machine is definitely your best choice. Its compact structure and small floor space are suitable for household use. In addition, this household laser cutting machine is simple to operate, even for a novice. You can use it to make many non-metal products, such as decorations, ornaments, jewelry, accessories, household items, etc.