Nowadays, Plywood laser cutting method is gradually becoming an outstanding laser cutting method. And it has a wide range of uses. But what’s the plywood? It is known that plywood is a kind of material made of multiple thin layers of wood veneer. And every two adjacent veneers are vertical to each other. Then, the wood chips are glued and pressed together under a certain temperature and pressure. However, different users have different processing requirements. And various types of plywood laser cutting machines also have disparate processing materials and fields. So how to choose a suitable and cost-effective plywood laser cutting machine? It has already become one of the most concerning issues for users.

As a professional CNC engraving machine manufacturer, DXTECH possesses decades of experience in the CNC engraving machine industry. We will help you analyze the following aspects, such as the definition, the function, your requirements, your budget, and so on. And our ultimate goal is nothing more than to help users as much as possible to know more about plywood laser cutting and pick a suitable plywood laser cutting machine. So, next, we will take you to understand plywood laser cutting from the following aspects.

What is the plywood laser cutting machine?

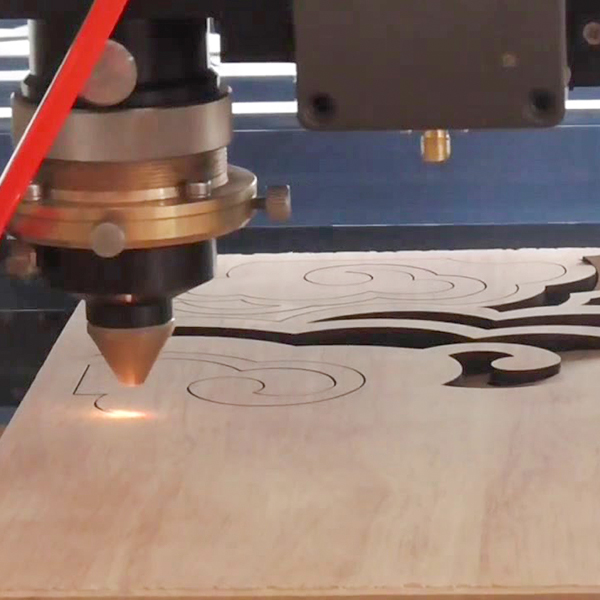

Plywood has many advantages, such as strong bending resistance, good moisture resistance, and outstanding non-deformation. Therefore, more and more consumers prefer plywood laser cutting and plywood engraving. Moreover, the projects and products of plywood laser cutting and plywood engraving are also found in many fields. As an excellent laser cutting method, plywood laser cutting needs some suitable equipment to laser cut plywood panels. So what kind of machine is suitable for plywood laser cutting and plywood engraving?

As we all know, CO2 laser cutting machine adopts advanced CO2 laser technology. It is mainly used for the laser engraving and laser cutting of nonmetal. So it is very appropriate for plywood laser cutting and plywood engraving. The names of these machines are derived from their materials, and these machines are essentially CO2 laser cutting machines. The working material of the CO2 laser machine is CO2 gas, and the auxiliary gas includes nitrogen, helium, xenon, and hydrogen. This machine has efficient energy conversion and good stability. When it begins to laser cut plywood panels, its speed can reach up to 25%. Also, the CO2 laser cutting machine can be used to process wood products, plywood, paper, leather, cloth, acrylic, etc., and cut or engrave them into different shapes to satisfy our demand.

What can the plywood laser cutting machine do?

The plywood laser cutting machine has good cutting quality, narrow cut width, and high cutting accuracy. The cutting seam can be welded without reprocessing. It has fast cutting speed, small deformation, and remarkable safety cleanliness. Hence, the plywood laser cutting machine is generally fitted for special parts. Especially those that require uniform cutting and non-metallic materials used in service industries. such as advertising and decoration, which require a thickness of no more than 20 mm. And the other is the processing of workpieces with complex cutting contours but small quantities. Used to save the time and cost of manufacturing molds.

At the same time, the plywood laser cutting machine can be used to cut Type I plywood, which is mostly used in aviation, ships, carriages, packaging, water conservancy projects and other fields. It can also be used to cut Type II plywood panels, mostly used in carriages, ships, furniture, and building decoration and packaging. Lastly, it can be used to cut Type III plywood, mostly used for furniture, packaging and general construction purposes.

Plywood laser cutting projects

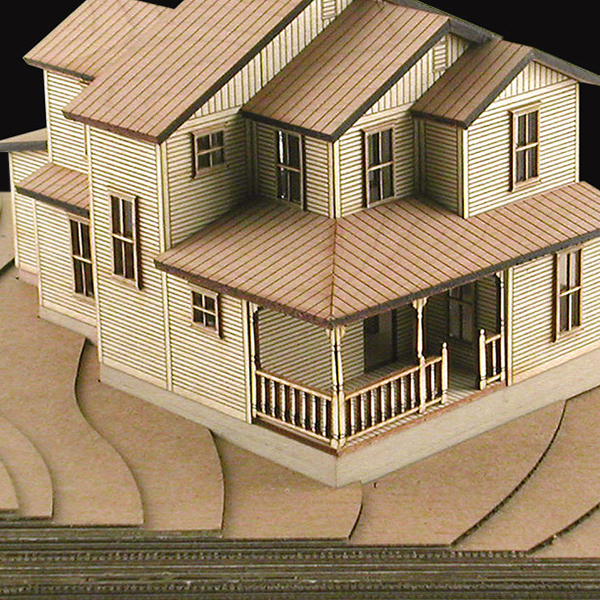

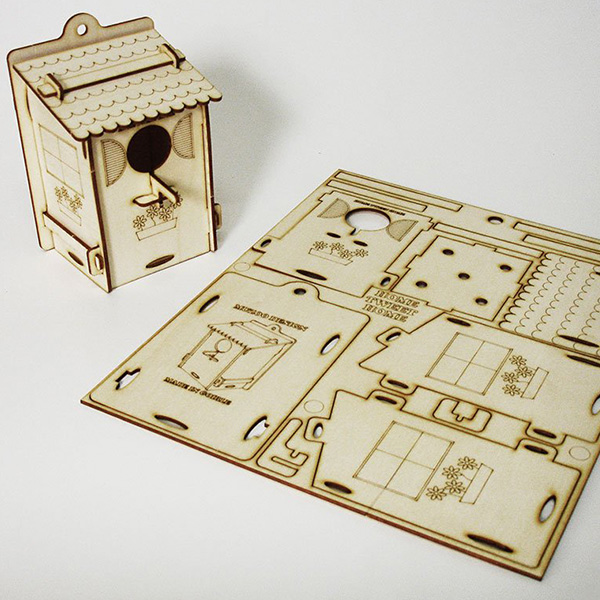

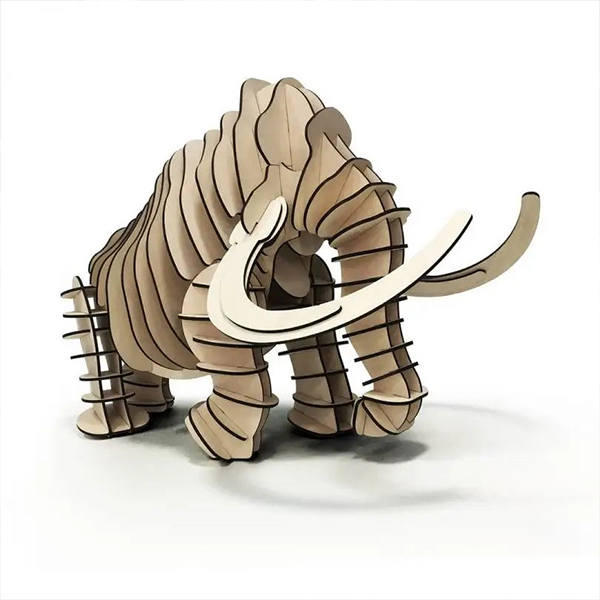

Plywood is widely used in many industries because it has a lot of advantages. And plywood laser cutting machine is a typical laser cutting machine specially designed to cut some different plywood panels. Its biggest advantage is that it can give full play to the characteristics of plywood materials and laser technology. So next, let me lead you to take a brief look at some plywood laser cutting and projects and plywood laser engraving products. Maybe You can get some inspiration from these projects. And then you can have a try to make your own custom plywood laser cutting and engraving products.

First of all, plywood decorations are deeply loved by the decoration and furniture industries. The picture below shows two laser-cut plywood decorations. The first is a beautiful laser-cut plywood pendant. It can be used to decorate the wall and increase the beauty of the room. The second is a laser-engraved plywood clock, which is both beautiful and practical.

Secondly, laser cutting and engraving plywood can also be made into small toys of various shapes. On the one hand, laser-engraved plywood is more environmentally friendly than toys made of plastic and metal. On the other hand, you can assemble by yourself, which is more practical and more interesting. And the finished toys can also be used for collection. Besides, if you want to give it to your friends as a present, it is more considerate.

Machine Recommendation

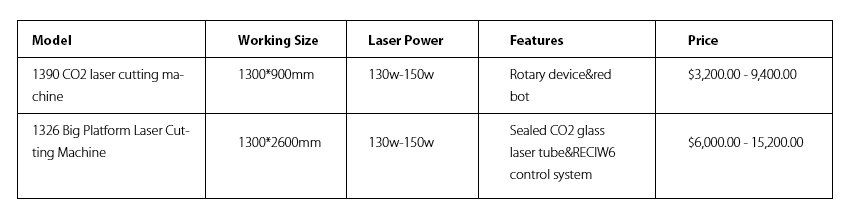

1.1390 CO2 Laser Cutting Machine

First of all, the laser cutting machine is equipped with a protective cover, which not only ensures the personal safety of the operator but also makes the entire processing more environmentally friendly. In the meantime, the equipment uses an imported laser head. It can effectively improve work efficiency with a maximum speed of 1200mm/s. It also uses professional engraving optical lenses and precise rear red light positioning to make the engraving more precise and the beam more stable. Its commonly used processing materials include acrylic, glass, wood, cloth, plastic, cardboard, MDF, marble and other non-metallic materials. And they are widely used in advertising processing, gift processing, packaging engraving, product identification, Seal engraving and many other industries.

2.1326 Big Platform Laser Cutting Machine

The structure of the laser cutting machine is well-designed and manufactured to ensure the stability and accuracy of the work. The transmission gear is made of high-quality copper, which makes it more durable and corrosion-resistant. Its electrical and overload protection design can not only ensure personal safety but also extend the life of the machine.

How to Choose Plywood Laser Cutting Machine

1.What kind of configuration do you prefer?

First of all, it is very important to understand your processing requirements. Don’t try to buy an all-around machine to process all kinds of plywood. Because each plywood laser cutting machine has its processing materials and applications.

Moreover, the operation of powerful machines is relatively complicated. However, our operating ability is limited, especially for those novices. Thus, it is enough to buy a machine that best suits the industry you want to work in. Finally, you can get the most suitable plywood laser cutting machine.

If your job is mainly engaged in construction and industrial industries, or you are often laser engraving plywood, the plywood panels you used are almost made of 2mm laser plywood or 3mm laser plywood. It means that it does not require a large processing depth for 2mm laser plywood. Then you can choose our lower power 1390 Laser Cutting Machine. I think it is enough to complete your task.

But if you plan to produce doors or hardwood furniture, then the 1326 Big Platform Laser Cutting Machine is a good choice. Because their surfaces are usually made of 3mm laser plywood or even thicker plywood panels. Therefore, they are helpful for laser cutting 3mm plywood. For instance, it can help you laser cut birch plywood.

Secondly, if conditions permit, it is best to visit the processing plant. You can check the equipment configuration, debug the equipment operation, exchange pre-sale and after-sale services, and observe the office status and environment of their business personnel. In short, if you understand your needs in an all-around way, do some investigation of the machine and the manufacturer in advance. As a result, you will buy a plywood laser cutting machine that suits your heart.

2.How about your processing requirements?

The machine configuration is closely related to the specific processing requirements. So, this can also be used as a standard for you to choose a plywood laser cutting machine. For example, you can choose a machine according to the spindle, work surface, motor, drive, control system and motor power. Generally speaking, the size of the selected laser cutting machine should be able to engrave or cut your largest material. For example, if you want to laser cut plywood panels, specifically laser cut birch plywood with a larger size, then 1326 Big Platform Laser Cutting Machine is a good choice. Because the worktable of these two machines is large enough. But if you need a lower power machine, then you can already choose the 80w 1390 Laser Cutting Machine.

3.How to choose within budget?

First of all, we must understand that it is not that the higher the price, the better the product. In addition, don’t blindly pursue low prices. Low-priced machines may sacrifice machine quality. Therefore, the only products that meet our needs are the best, and the plywood laser cutting machine is no exception.

Second, it is very important to know how much the laser cut plywood cost you can pay and afford. You need to know exactly what your budget limit is. And then choose the machine that best meets your requirements of laser cut plywood costs. Because there are many types of machines, there may be a big price difference.

If you have a sufficient budget and you care more about the overall performance of the machine than the price, then we recommend that you purchase the 1326 Big Platform Laser Cutting Machine. They are two high-precision and fast plywood laser cutting machines. But if you are more pursuing a good price ratio, then the 1390 CO2 laser cutting machine is a good choice. It is not much different from the 1326 Big Platform Laser Cutting Machine in terms of performance and configuration, but the price can be nearly half cheaper.

4.Which brand should you pick?

There are many plywood laser cutting machine manufacturers and machine products on the market. So, how do we choose?

First of all, before buying a certain brand of machine, we must conduct a detailed investigation of its manufacturer. For example, it is brand reputation, research and development capabilities, production capabilities, delivery capabilities, product quality, customer reviews, etc. On the one hand, you can do this by checking the manufacturer’s company website. On the other hand, you can survey the customers who bought their products.

DXTECH has a professional team and qualified employees. We have an in-depth understanding of laser machines. And we can provide you with all-day online and offline services, including machine support, machine model selection as well as customized production solutions. In addition, we also have a complete service system. It’s convenient to solve all problems arising from pre-sale service, in-sales service and after-sales service. Responding to user needs as soon as possible is our most sincere commitment. We always have been adhering to it and implementing it in practical actions. If you have any questions or needs, you are welcome to leave a message or contact us. We will do our best to provide you with the best quality service and meet all your product needs.

conclusion

The above are some main methods for our analysis of how to choose a plywood laser cutting machine. First of all, we need to understand the background of the plywood laser cutting machine. And then we should be familiar with the types of plywood laser cutting machines. We should know the advantages of their configuration and whether they meet our processing requirements and planned budget.

Secondly, we also need to know the relevant information of the machine manufacturer, such as the monthly sales volume, the pre-sales and after-sales service, and the customer evaluation.

According to the above methods, We can be more organized and faster to find the right plywood laser cutter for our needs. If you think this article is helpful to your purchase of the plywood laser cutting machine, please pay attention to me. Or, you can leave a message to tell me the knowledge and topic of the laser cutting machine you want to know.