Recently, DXTECH welcomed customers from the Netherlands to visit our factory. The customer is engaged in the machining industry. Their arrival is not only an on-site inspection of the technical strength of the DXTECH factory but also an in-depth recognition of our brand and products. With great excitement, we warmly welcome these friends from afar and look forward to working with them to create brilliance in the days to come.

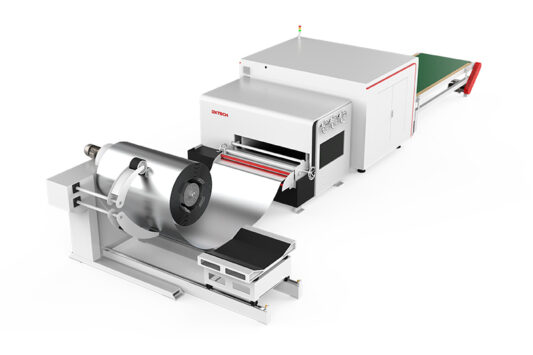

The focus of this inspection is our DXTECH’s main machines: laser cutting machines, pipe machines, welding machines, and bending machines. These equipment not only represents DXTECH’s latest achievements in the field of machining but also reflects our unremitting pursuit of precision, speed, and efficiency.

During the inspection, our sales manager Demi personally led a team of technical experts to provide detailed explanations and vivid demonstrations to Dutch customers. Manager Demi first introduced the unique advantages of the DXTECH laser cutting machine to customers. He emphasized that this laser-cutting machine adopts industry-leading laser technology and a high-precision control system, which can greatly improve production efficiency while ensuring cutting accuracy. Whether it is a thin metal sheet or a steel plate with a thickness of tens of millimeters, the laser cutting machine can easily handle it and complete the high-quality cutting task in one go.

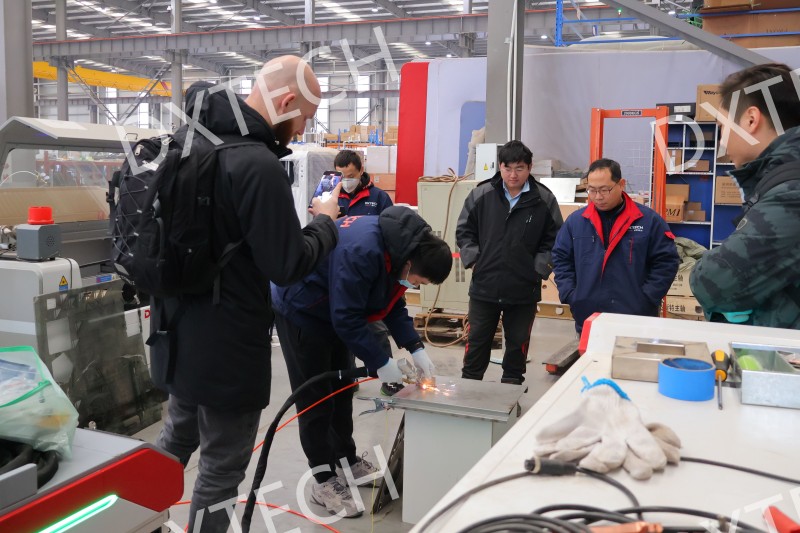

The technical experts then demonstrated the actual operation process of the laser cutting machine to the customers. Under the precise illumination of the laser beam, a metal plate is quickly cut into a preset shape, and the entire process is smooth and efficient. Dutch customers came forward to observe and expressed their sincere admiration for the accuracy and efficiency of the laser-cutting machine.

In addition to laser cutting machines, DXTECH’s pipe machines, welding machines, and bending machines have also attracted the attention of Dutch customers. The pipe machine has won unanimous praise from customers for its flexible processing capabilities and high-precision pipe processing effects; the welding machine has won the recognition of customers for its stable welding quality and high operating efficiency; and the bending machine has won unanimous praise from customers. With its powerful bending ability and high-precision bending effect, it meets customers’ needs for various complex shapes.

Dutch customers also spoke highly of DXTECH’s professional team and high-quality services during the inspection process. They said that DXTECH not only has advanced equipment and technology but also has a professional, efficient, and enthusiastic team that can provide customers with a full range of services and support. This is one of the important considerations when choosing a partner.

At the end of the inspection, Manager Demi expressed his strong intention for future cooperation with the Dutch customers on behalf of DXTECH. He said that DXTECH always adheres to customer-centered, technology-driven and is committed to providing customers with the highest quality products and services. He looks forward to establishing long-term and stable cooperative relationships with Dutch customers and jointly promoting the development and innovation of the mechanical processing industry.

The visit of the Dutch customer not only deepened the understanding and trust between the two parties but also laid a solid foundation for the cooperation between DXTECH and the Dutch machining industry. We firmly believe that in the days to come, DXTECH will work hand in hand with partners in the Netherlands to create a bright future for the machining industry jointly!

If you are also interested in visiting the DXTECH factory, please feel free to contact us.