With the continuous development of science and technology, laser cutting technology has been widely used in the manufacturing industry due to its high precision, high efficiency, and high flexibility. Especially in the cabinet industry, the introduction of metal laser cutting machines not only improves production efficiency and product quality but also promotes innovation and development in the industry.

Overview of metal laser cutting machine technology

Metal laser cutting machines use high-energy laser beams to irradiate the metal surface to quickly melt, vaporize, or reach the ignition point of the material. At the same time, the melted or burning material is blown away by high-speed airflow to achieve the purpose of cutting. This technology has the advantages of fast cutting speed, narrow cutting slit, small heat-affected zone, and flat and smooth cutting surface. It is especially suitable for cutting complex graphics and fine structures.

Metal applications in the cabinet industry

Cabinets are an indispensable part of home life, and their material and appearance design directly affect the overall style and quality of the home. In cabinet manufacturing, metal materials are widely used in cabinet frames, door panels, drawer panels, and other parts due to their durability, beauty, and easy cleaning. Especially in the design of modern minimalist-style cabinets, metal materials play an irreplaceable role.

Application advantages of metal laser cutting machines in the cabinet industry

1. Improve production efficiency

Metal laser cutting machines can achieve fast and accurate cutting, greatly improving the efficiency of cabinet production. Compared with traditional mechanical cutting methods, laser cutting reduces the time for process conversion and tool replacement, making the production process more compact.

2. Improve product quality

The accuracy of laser cutting is as high as a millimeter, and the slits are small and uniform, ensuring the dimensional accuracy and appearance quality of the metal parts of the cabinet. At the same time, the heat-affected zone generated during laser cutting is small, which avoids the problems of material deformation and stress concentration, and improves the stability and durability of the product.

3. Expand design space

Laser-cutting technology can easily handle the cutting of various complex graphics and curved structures, providing cabinet designers with greater creative space. Designers can design more personalized and artistic cabinet products based on market demand and consumer aesthetics.

4. Reduce production costs

Although the initial investment cost of metal laser cutting machines is high, in the long run, their efficient production capacity and low scrap rate can significantly reduce production costs. In addition, the laser cutting machine can also be used for multiple purposes and cut metal materials of different types and thicknesses, further improving the utilization rate of the equipment.

5. Promote industrial upgrading

The application of metal laser cutting machines has promoted technological progress and industrial upgrading of the cabinet industry. With the continuous development and improvement of laser cutting technology, the cabinet industry will realize the transformation from traditional manufacturing to intelligent manufacturing, improving the competitiveness of the entire industry.

Challenges and prospects

Looking to the future, with the continuous innovation and upgrading of laser technology, metal laser cutting machines will play a more important role in the cabinet industry. At the same time, with the rapid development of intelligent manufacturing and the industrial Internet, metal laser cutting machines will be combined with other intelligent equipment to achieve a more efficient and intelligent production model, pushing the cabinet industry to a higher level.

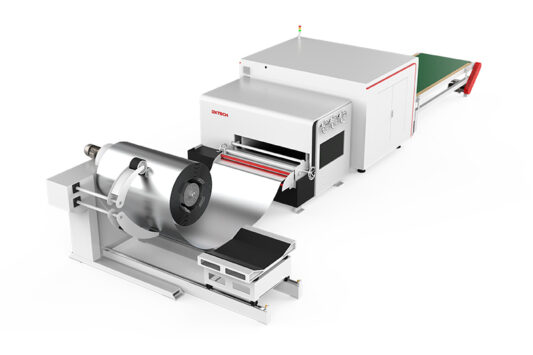

As a professional metal laser-cutting equipment manufacturer, DXTECH has been committed to providing high-quality, high-performance, and efficient laser cutting solutions to customers around the world, and has won widespread praise and trust. Our machines are delivered as complete units, ready for use after the bed and external equipment are connected.

If you are interested in DXTECH laser cutting machine, please feel free to contact us. We will provide you with the best service and technical support.