In modern manufacturing, laser cutting machines have gradually become mainstream equipment in the field of metal processing due to their high efficiency, high precision, and high automation. How to judge the cutting quality of laser cutting machines is a concern of every manufacturing company. This article will focus on this topic and analyze six key criteria in detail to help you fully understand the performance of laser-cutting machines.

1. The neatness of cutting edges

The most basic task of a laser cutting machine is to cut various metal materials, and the neatness of the cutting edges is an important indicator of its performance. A high-quality laser-cutting machine should be able to maintain neat and clear cutting edges at various speeds and power settings. Neat edges not only improve the aesthetics of the product but also ensure the effective use of materials.

2. Cutting speed and efficiency

For manufacturing companies, time is money. The cutting speed and efficiency of the laser cutting machine directly affect production efficiency and cost. An efficient laser-cutting machine can cut a large number of materials in a short time and can adjust the speed according to different materials and thicknesses to ensure cutting quality while improving production efficiency.

3. Accuracy of cutting depth

Different materials and thicknesses have different requirements for the cutting depth of laser cutting machines. A high-quality laser cutting machine should be able to accurately control the cutting depth to ensure that each cut can reach the preset depth and avoid over-cutting or under-cutting.

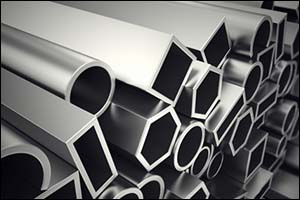

4. Adaptability to various materials

In actual production, manufacturing companies often encounter a variety of materials with different properties. Therefore, the laser cutting machine should have good material adaptability and be able to complete cutting tasks of various materials quickly and accurately. This not only improves production efficiency but also reduces processing errors caused by material problems.

5. Roughness of cutting surface

The roughness of the cutting surface directly affects the quality of subsequent processing and the product’s service life. A high-quality laser cutting machine should be able to provide a smooth and clean cutting surface, reduce the difficulty of subsequent processing, and improve the overall quality of the product.

6. Stability and reliability of equipment operation

Any equipment may have various problems under long-term and high-intensity work, and laser cutting machines are no exception. However, high-quality laser cutting machines have good stability and reliability and can maintain good performance under long-term continuous operation and reduce production interruptions caused by equipment failure. To ensure the stable operation of equipment, manufacturing companies should regularly maintain and maintain equipment to ensure that it is in optimal working condition.

To sum up, judging the cutting quality of a laser cutting machine mainly depends on the neatness of the cutting edge, cutting speed and efficiency, accuracy of the cutting depth, adaptability to various materials, roughness of the cutting surface, and equipment operation. Six aspects of stability and reliability. When choosing a laser cutting machine, manufacturing companies should comprehensively consider these six criteria based on their own processing needs and production characteristics, and choose the equipment that best suits them. At the same time, to ensure the long-term stable operation of equipment, manufacturing companies should also pay attention to the maintenance and upkeep of equipment.

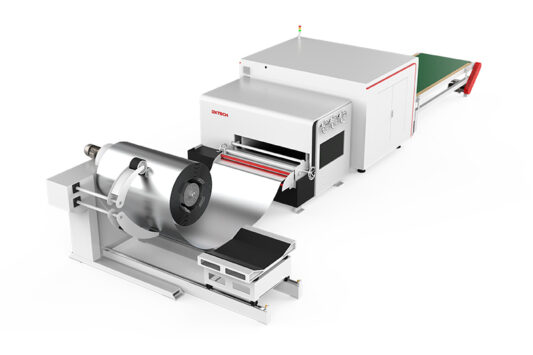

As a supplier with outstanding technical strength, high-quality products, and professional services, DXTECH is worthy of our recommendation and choice. Their fiber laser cutting machines have excellent performance and features that can meet various complex processing needs with high cutting quality. When you choose DXTECH, you will get high-quality equipment and comprehensive technical support, bringing more value and benefits to your production.