With the rapid development of science and technology, metal plate and tube laser cutting machines have become increasingly prominent in the manufacturing industry. As an advanced processing equipment, the metal plate and tube laser cutting machine is gradually changing the pattern of the traditional metal processing industry with its unique advantages.

First of all, the metal plate and tube laser cutting machine has an ultra-high processing speed. Compared with traditional mechanical cutting, laser cutting is several times faster. This not only greatly improves production efficiency, saves valuable time and resources for enterprises, but also makes large-volume, continuous production possible. In the modern manufacturing industry that pursues high efficiency and short cycles, this advantage undoubtedly brings huge competitive advantages to enterprises.

Secondly, the metal plate and tube laser cutting machine has extremely high cutting accuracy. Through advanced computer control technology, lasers can accurately act on materials to achieve high-precision cutting of complex shapes. This not only meets the strict requirements of modern manufacturing for product accuracy but also provides designers with greater creative space so that the appearance and performance of the product can be perfectly displayed.

Furthermore, the metal plate and tube laser cutting machine has strong adaptability. Whether it is a piece of metal as thin as paper or a thick metal pipe, the laser cutting machine can handle it easily. This wide applicability allows companies to easily cope with the processing needs of different materials and thicknesses without the need to replace or adjust equipment, greatly improving production efficiency.

In addition, metal plate and tube laser cutting machines have a high degree of automation. Through integration with automation systems, laser cutting machines can achieve 24-hour unattended operation. This not only reduces the labor intensity of workers and reduces the impact of human factors on product quality, but also further improves production efficiency and reduces production costs.

At the same time, the cut quality of the metal sheet and tube laser cutting machine is very good. Since laser cutting is a non-contact process, the material will not be squeezed and rubbed by mechanical forces during the cutting process, so the cutting edge is smooth and flat, and no subsequent processing is required. This not only reduces the production process and production costs but also improves product quality and aesthetics.

What’s more worth mentioning is that the metal plate and tube laser cutting machine has a high material utilization rate. Through precise layout and cutting control, companies can minimize material waste and improve resource utilization. In today’s world where green and environmental protection is advocated, this advantage has undoubtedly brought a good social reputation and economic benefits to the company.

Finally, the metal plate and tube laser cutting machine meets the requirements of environmental protection and energy saving. Compared with traditional machining, laser cutting does not require the use of tools, reducing tool wear and waste generation. At the same time, the energy consumption of laser cutting is relatively low, saving energy costs for enterprises, and also conforms to the concept of green and sustainable development.

To sum up, metal plate and tube laser cutting machines are becoming important tools in modern manufacturing due to their significant advantages such as fast processing speed, high precision, strong adaptability, high degree of automation, good incision quality, high material utilization rate, environmental protection, and energy saving. Outstanding. It not only greatly improves production efficiency and product quality, but also leads the manufacturing industry to develop in a more efficient and environmentally friendly direction.

However, with the continuous development of technology, we believe that the advantages of metal plate and tube laser-cutting machines will continue to expand. In the future, it will be applied and promoted in more fields and create more value for mankind. Let us look forward to a more brilliant future for this new manufacturing star!

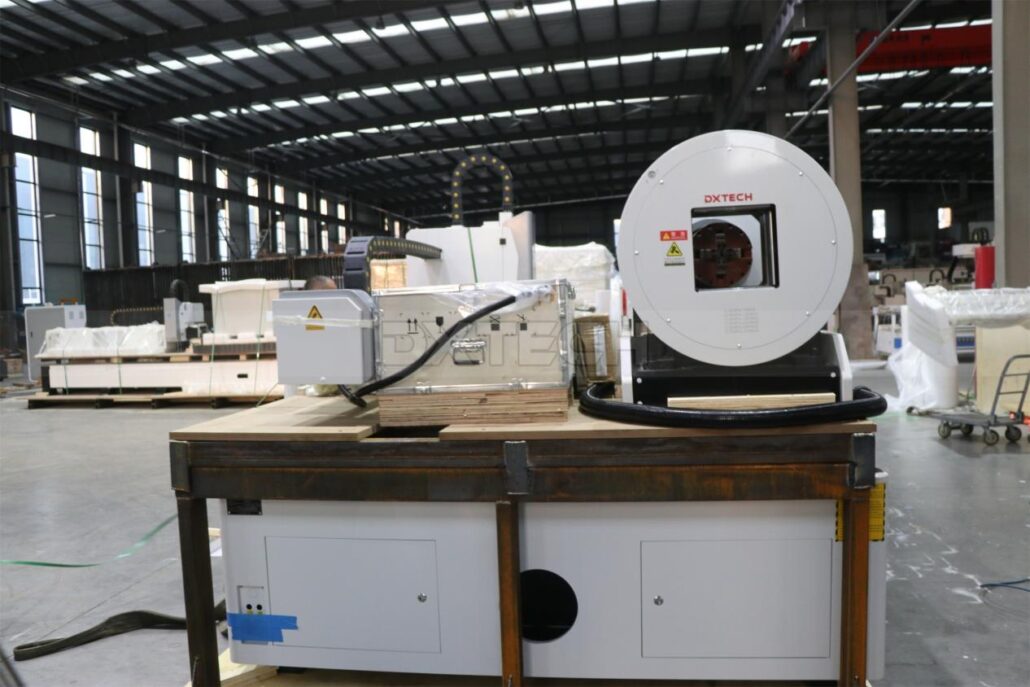

If you are interested in the DXTECH metal sheet and tube laser cutting machine, please get in touch with us.