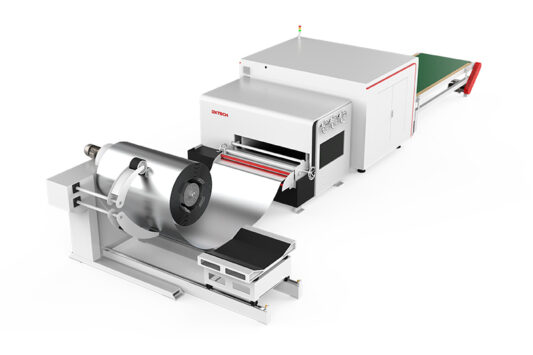

With the advancement of science and technology, laser cutting technology has gradually occupied a place in various industries. Especially in the steel industry, the application of fiber laser cutting machines has brought revolutionary changes. This article will delve into the advantages of fiber laser-cutting machines in the steel industry and how they can help companies improve production efficiency and reduce costs.

High-precision and high-quality cutting

Fiber laser cutting machines use advanced laser technology and have high-precision, high-quality cutting capabilities. Compared with traditional cutting methods, fiber laser cutting machines can complete high-quality cutting in a short time, and the cutting edges are smooth, reducing the cost of subsequent processing. This greatly improves the production efficiency of steel companies and ensures product quality.

Powerful material processing capabilities

Fiber laser cutting machines have wide adaptability to various materials. Whether it is stainless steel, carbon steel, or other alloy materials, fiber laser cutting machines can easily handle it. This allows companies to more flexibly adjust production to meet rapid market changes when faced with diversified product demands.

Energy saving and environmental protection

During the operation of the fiber laser cutting machine, the energy utilization rate is high and it can effectively reduce energy consumption. At the same time, due to its precise cutting capabilities, it reduces material waste and saves costs for enterprises. In addition, the environmental protection characteristics of fiber laser cutting machines have also been widely recognized. It generates less waste during the production process and has little impact on the environment, which is in line with the green development concept of modern enterprises.

Easy maintenance and high stability

The fiber laser cutting machine has a compact structure and is relatively easy to maintain. Its modular design allows the equipment to quickly find the problem when it malfunctions, reducing maintenance costs. In addition, the fiber laser cutting machine has high stability and is not prone to failure when working continuously for a long time, saving enterprises a lot of manpower and time costs.

Intelligence and automation

With the advancement of Industry 4.0, intelligence and automation have become inevitable choices for modern enterprises. Fiber laser cutting machines have advanced CNC systems that enable precise positioning and cutting. Enterprises can use intelligent production management systems to remotely control and monitor fiber laser cutting machines, grasp the operating status of the equipment in real time, and improve production management efficiency. At the same time, automated production reduces the impact of human factors on product quality, further ensuring product stability and consistency.

In summary, fiber laser cutting machines have shown significant advantages in the steel industry. It not only improves the company’s production efficiency and product quality, but also saves costs, protects the environment, and promotes transformation and upgrading. In the future, with the continuous advancement of technology and the expansion of application fields, the application prospects of fiber laser cutting machines in the steel industry will be even broader. Steel companies should seize this opportunity and actively introduce fiber laser cutting machines to enhance their competitiveness to cope with market challenges and opportunities.

DXTECH is a professional fiber laser cutting machine manufacturer with 13 years of export experience. If you are interested, please contact us.