What is a fiber laser cleaning machine?

The fiber laser cleaning machine is mainly used for heavy rust removal and decontamination of metals, so it is also called a metal laser cleaning machine or a metal descaling machine. Using a laser cleaning machine can effectively remove the metal oxide layer and paint dirt on the surface. To quickly remove dust, coating, paint, oil and other pollutants on the surface of the workpiece. The designer carefully designed and manufactured, the mechanical structure is compact, and the operation and movement are very convenient. This machine is widely used in all walks of life and is an ideal choice for many businesses.

How does the fiber laser cleaning machine work?

Laser cleaning techniques work by sending nanosecond-long laser pulses to the surface of a workpiece. When a laser beam interacts with laser-absorbing contaminants, the contaminant or coating particles either turn into a gas, or the pressure of the interaction causes the particles to break free from the surface. Since the underlying material doesn’t absorb any energy, it stays the same.

By controlling the laser fluence, wavelength and pulse length, the area of material removed by a single laser pulse can be extremely precisely controlled. The use of laser cleaning machines is suitable for rapid and deep rust removal, paint removal, and only removes the surface coating or oxide of the workpiece without damaging the substrate.

Why Choose Fiber Laser Cleaning Machine?

1. Advantages of cost saving

Laser cleaning machines can be more expensive than other traditional cleaning equipment, however, the investment pays for itself within the first year of use. The laser cleaning machine can be used at any time, and the portable design is convenient to move, making it work in a wider range. No consumables are required, the laser cleaning system can be started after power-on, and the operating cost is only equivalent to a PC desktop.

2. Advantages of safety and environmental protection

Laser cleaning technology is environmentally friendly. They emit no greenhouse gases and produce no chemical waste during laser rust or paint removal. This is in stark contrast to traditional cleaning methods, where dry ice blasting or cleaning with chemicals inevitably contaminates water flows and the Earth’s atmosphere.

It is not necessary to be equipped with a full set of protective equipment during laser cleaning operations, just wear laser protective glasses. The whole cleaning process is very safe and will not cause harm to the health of the laser cleaning machine operator.

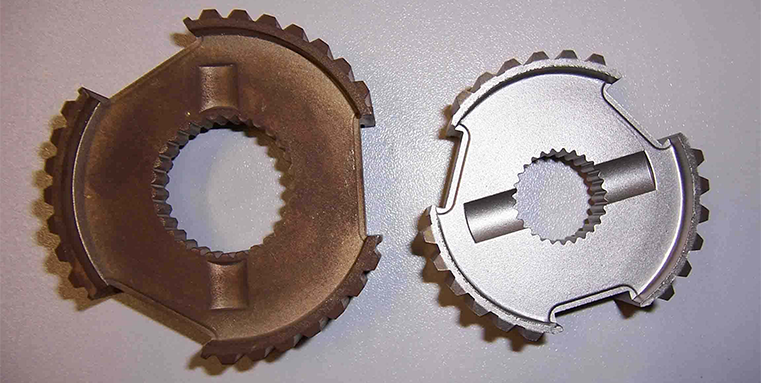

3. Advantages of precise cleaning of workpieces

Unlike blast cleaning, laser cleaning is selective. It can easily focus on very small spots or areas without affecting adjacent materials. Precise and spot cleaning is easier with a laser cleaning machine. Additionally, laser cleaning technology makes it easier to reach the corners of intricately designed objects. The final product after laser cleaning is much finer than other cleaning methods.

Laser cleaning machine is a new generation of high-tech industrial cleaning equipment, which is easy to install, control and realize automation. Simple operation, turn on the power, turn on the device, and you can realize the cleaning without chemical reagents, medium and water. In addition to laser rust removal and laser paint removal, it can also remove resin, grease, stains, dirt, cement, oxides and other pollutants on the surface of objects.

If your product is covered with pollutants – including rust, oil, cement, oxide, paint or others, DXTECH laser cleaning machine can efficiently complete the item cleaning. Not only metal cleaning, including porcelain, glass, rubber, plastic and other non-metallic materials can be cleaned.