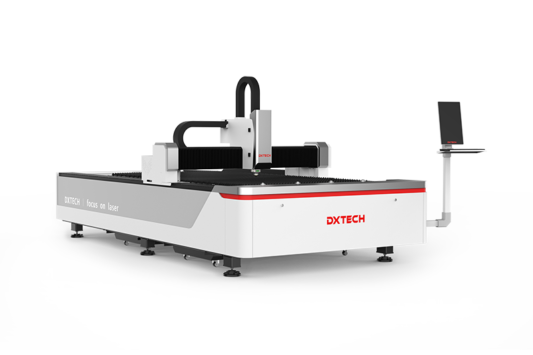

As high-tech cutting equipment, laser cutting machines have gradually emerged in the sheet metal industry in recent years and have become the new favorite of the industry. The DXTECH laser cutting machine has demonstrated its excellent performance and advantages in the sheet metal industry, injecting new vitality into the rapid development of the industry. So, why can laser cutting machines occupy the sheet metal industry market?

First of all, laser cutting machines have excellent processing quality. Compared with traditional mechanical cutting methods, laser cutting machines use high-energy laser beams to cut. The slits are narrow and the appearance after cutting is smooth and clean without the need for subsequent processing. For the sheet metal industry, this means higher processing accuracy and lower subsequent processing costs, which greatly improves production efficiency. DXTECH laser cutting machine can maintain stable laser output power during the cutting process, ensuring stable and reliable cutting quality, and providing a high-quality solution for sheet metal processing.

Secondly, laser cutting machines are highly automated and intelligent. DXTECH laser cutting machine adopts an advanced control system and programming software, which can realize fully automatic or semi-automatic processing processes. Through the programming software, users can easily set the cutting size and cutting path to achieve fast and efficient cutting. This automated and intelligent production method not only reduces the tediousness of manual operations and reduces the labor intensity of operators, but also reduces errors caused by human factors and improves production efficiency and product quality.

In addition, laser cutting machines offer flexibility and wide applicability. Whether it is a simple straight-line cutting or a complex curved cutting, the laser cutting machine can handle it easily. Moreover, laser cutting machines can process various metal materials, including stainless steel, aluminum alloy, carbon steel, etc., meeting the diverse processing needs of the sheet metal industry. DXTECH laser cutting machines are particularly outstanding in terms of material adaptability and can easily cope with the cutting needs of various materials, providing a broader application space for the sheet metal industry.

Furthermore, the environmental performance of laser cutting machines is also one of the important reasons why they are favored by the sheet metal industry. Traditional mechanical cutting methods often produce a lot of noise and dust pollution, posing certain threats to the environment and the health of operators. The laser cutting machine is almost noiseless and pollution-free during the processing process, realizing a green and environmentally friendly production method. This is in line with the current society’s increasing requirements for environmental protection, making laser cutting machines more competitive in the sheet metal industry.

Finally, the popularity and cost reduction of laser cutting machines are also important factors that enable them to occupy the sheet metal industry market. With the continuous development and maturity of laser technology, the manufacturing cost of laser cutting machines has gradually decreased, allowing more sheet metal companies to afford the cost of purchasing and using laser cutting machines. At the same time, a number of excellent laser cutting machine brands have emerged on the market, such as DXTECH, etc., which have won the favor of the majority of sheet metal companies with their excellent performance and high-quality services.

To sum up, the reason why laser cutting machines can occupy the sheet metal industry market is inseparable from their excellent processing quality, high degree of automation and intelligence, flexibility and wide applicability, environmental protection performance, and cost reduction. The advantages. As a leader in the industry, DXTECH laser cutting machines have injected new vitality into the development of the sheet metal industry with their excellent performance and high-quality services. In the future, with the continuous advancement of laser technology and the continuous expansion of application fields, I believe that the position of laser cutting machines in the sheet metal industry will be more stable and make greater contributions to the sustainable development of the industry. If you are interested in the DXTECH laser cutting machine, please contact us!