The performance of laser-cutting machines has been superior in recent years. Its laser-cutting process far surpasses the traditional cutting process in terms of appearance, efficiency, and stability. With the seemingly simple laser cutting, what is its cutting principle? Let’s take a look together below.

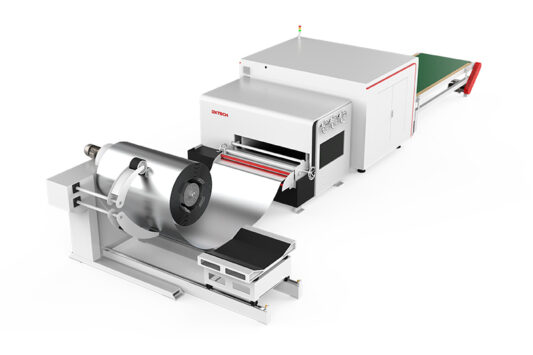

The principle of fiber laser cutting machine: fiber laser is to dope the pump material into the fiber, and the laser of a specific wavelength emitted by the semiconductor laser is combined to make the fiber generate laser and focus on the surface of the workpiece so that the workpiece is cut The area irradiated by the spot is instantly melted and gasified, and the computer-controlled numerical control mechanical system moves the position of the spot to realize automatic drilling. It is a high-tech equipment integrating laser technology, numerical control technology, and precision machinery technology.

Fiber laser cutting machine can process materials: can cut a variety of metal sheets, and pipes, mainly suitable for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized plate, pickling Plate, copper, silver, gold, copper and other metal sheet and pipe cutting.

The scope of application of fiber laser cutting machine: metal sheet processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, glasses industry, spring sheets, circuit boards, electric kettle, medical microelectronics, hardware, knife measuring tools, and other industries.

The fiber laser cutting machine has the following characteristics:

(1) The cutting-edge fiber laser is selected, with high photoelectric conversion efficiency and stable performance, and the service life of key components can reach 100,000 hours;

(2) There is no need to generate gas during laser generation, air-assisted cutting, or optical fiber transmission, and no need to adjust the optical path;

(3) The laser is transmitted by optical fiber without reflective mirrors, which can save a lot of maintenance costs;

(4) Compared with other medium laser equipment, the fiber laser cutting machine has a smaller focus spot, higher work efficiency, and better processing quality;

(5) Simple structure and small footprint;

(6) It can be used in any harsh working environment, that is, it has high adaptability to dust, vibration, shock, humidity, and temperature;

(7) High precision and fast speed, mainly for fast and precise cutting of metal plates below 4mm.

The processing advantages of fiber laser cutting machine are as follows:

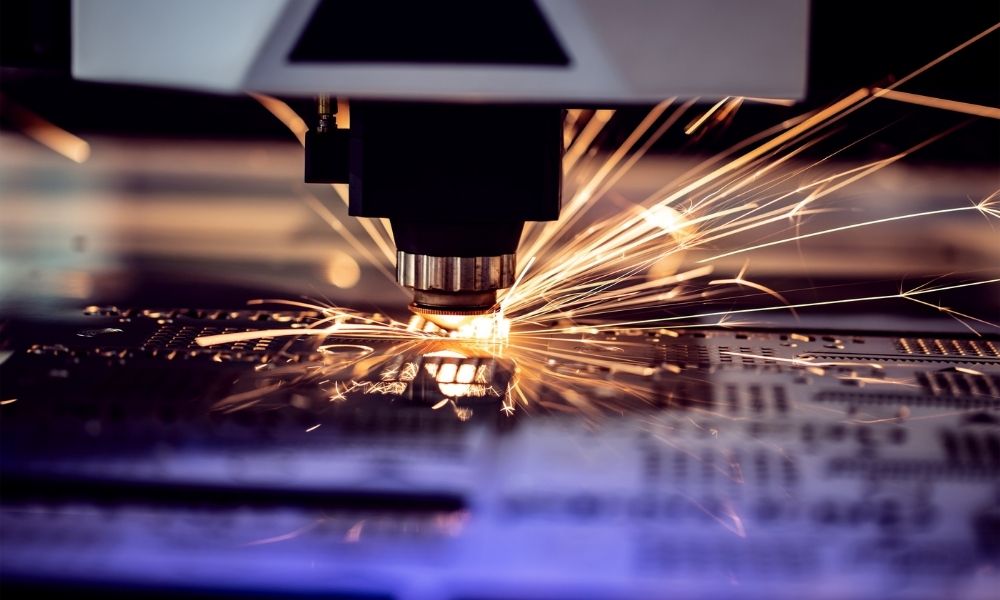

(1) High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cutting surface without burrs;

(2) The laser cutting head is not in contact with the surface of the material and will not scratch the workpiece;

(3) The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is small, and there is no mechanical deformation;

(4) Good processing flexibility, can process any graphics, and can also cut pipes and other special-shaped materials;

(5) It can cut any hard material such as steel plate, stainless steel, aluminum alloy plate, and hard alloy without deformation.