In the metal processing industry, people often use laser cutting and plasma cutting to cut metal materials. Both of them have relatively large market demands. So what are the differences and specific applications of these two cutting methods?

Below we will compare and discuss laser cut and plasma cut technology and their applications.

What is laser cutting?

Laser cut technology is to irradiate the workpiece with a focused high-power-density laser beam. Such laser will quickly melt, vaporize, ablate, or reach the ignition point of the irradiated material. At the same time, the high-speed airflow coaxial with the beam will blow away the molten material. And thus it realizes the cutting of the workpiece.

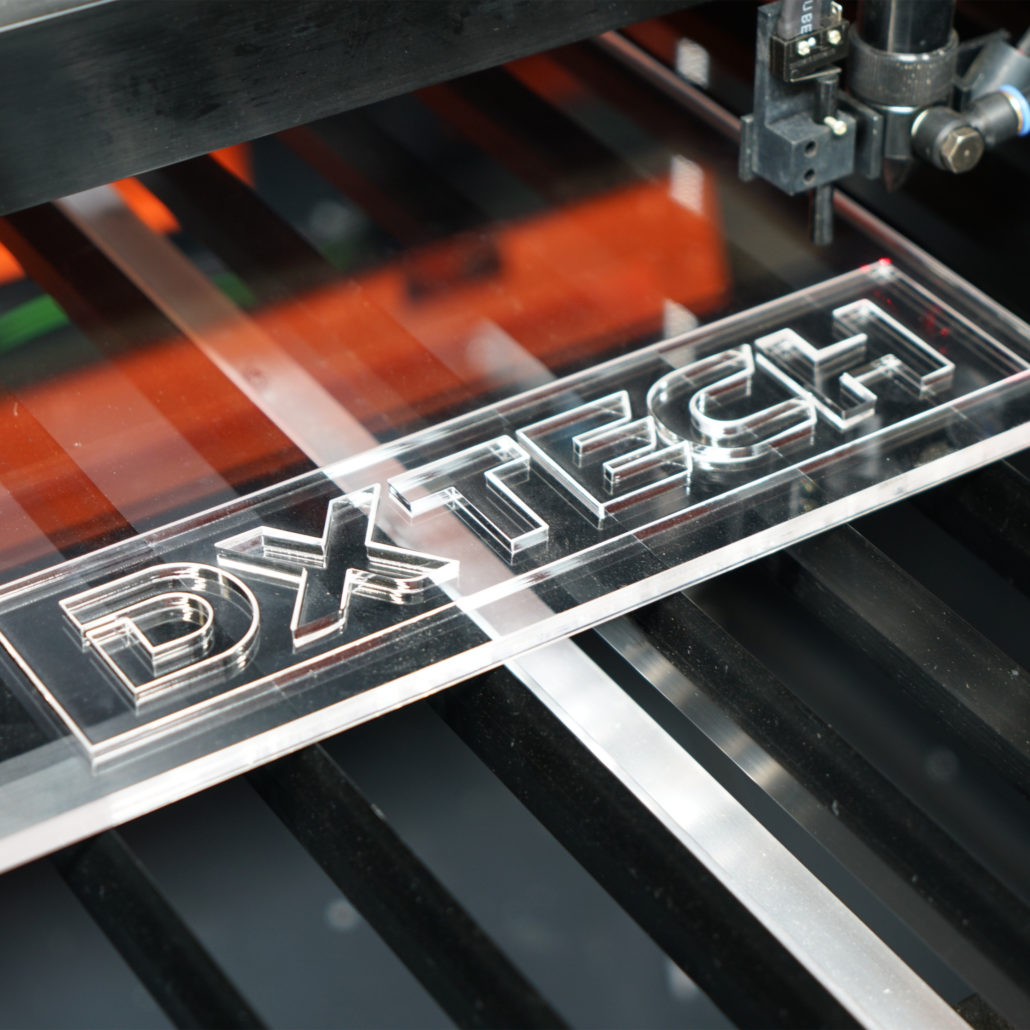

Currently, CO2 laser cutting machines generally cut non-metallic materials, such as wood, acrylic, leather, and fabric. Laser cut wood and laser cut acrylic are the materials that people use frequently in many industries. And the left video shows how a CO2 laser cutting machine cuts acrylic board.

And fiber laser cutting machine is applicable to cut metal, such as carbon steel, stainless steel, and galvanized steel sheet. In the building decoration and medical instrument industries, people often use laser cut metal and laser cut steel materials

What is plasma cutting?

Plasma cutting is a new type of thermal cutting process. And CNC plasma cutting machines use compressed air as the working gas. The high-temperature and high-speed plasma arc serve as the heat source to locally melt the metal to be cut. At the same time, the molten metal is blown away with the high-speed airflow to realize cutting. And the video at left is the plasma machine cuts metal material.

Plasma cut machine with different working gases can cut various metals that are difficult to cut with oxygen. Especially for cutting non-ferrous metals, such as aluminum, copper, titanium, and nickel, CNC plasma cutting machine is a good choice.

Comparison: Laser cutting VS Plasma cutting

Laser cutting VS Plasma cutting, which one is more suitable for you? We will compare these two kinds of cutting technology from the following six aspects.

Cutting thickness comparison

The application range of the laser cut machine is very wide. Regardless of metal or non-metal materials, it can cut. For cutting non-metals, such as cloth, leather, etc., you can use a CO2 laser cutting machine. For cutting thinner metal materials, such as stainless steel and carbon steel, a fiber laser cutting machine is optimal.

Plasma cut technology can only cut metal materials. It can cut various metal materials such as stainless steel, aluminum, copper, cast iron, and carbon steel. And the metal that plasma machines can cut is usually thicker than laser cut metal. Industrial manufacturers often use plasma cut materials widely in various machinery. There are industries such as automobiles, pressure vessels, chemical and engineering machinery, and steel structures.

Application range comparison

The cutting speed of the laser machine is faster than that of CNC plasma cutting machines. For 5mm thick polypropylene resin plates, the cutting speed of the CO2 laser cutting machine can reach 12000mm/min. The cutting efficiency that CNC plasma cutting machines can achieve is generally 8000mm/min.

Obviously, the laser cut speed is quicker and suitable for mass production. The plasma cut speed is slow and the relative accuracy is low. It is more suitable for cutting thick metal plates.

Cutting speed comparison

In the practical application, the carbon steel processed by laser cut is generally less than 20mm in thickness. According to laser power and performance, the laser cutting machine generally can cut carbon steel up to 40mm. And as the thickness of the workpiece increases, the laser cut speed decreases accordingly.

Comparatively, the plasma cutting machines are more suitable for cutting the thicker plates above 6mm with a low precision requirement. Theoretically speaking, the maximum thickness of a plasma laser cutting machine can reach more than 100mm.

Comparison of cutting accuracy

Laser cutting machine has higher cutting accuracy than plasma cut processing. The laser cut positioning accuracy can reach 0.05mm, and the repeat positioning accuracy is 0.02mm. Moreover, the laser cut seam is narrow and fine. And both sides of the cutting face are parallel and perpendicular to the surface. The plasma cutting is generally less precise than the laser cutting machine. And the plasma cut accuracy can reach within 1mm.

Comparison of cutting seam width

Laser cut processing is more precise than plasma cut, and the laser cut seam is small, about 0.5mm. The cutting seam of CNC plasma cutting machines is larger than laser cut processing, it is about 1-2mm.

Comparison of machine price

Different models of laser cut machines have different prices. Laser cut process needs no consumables, but the equipment investment cost is relatively higher than plasma cut processing. While the laser cut effect is precise and better than plasma cutting.

Plasma cut equipment is much cheaper than a laser cutting machine. According to the power and brand of plasma machine, the price is different. As long as it can cut all the conductive materials. But its cutting accuracy is not as good as that of laser cut technology.

Applications of laser cutting and plasma cutting

At below, we will introduce different laser cut and plasma cut applications respectively.

Laser cut material applications

Laser cut processing has a very wide range of applications. Let’s have a look at what materials and industries that laser cut technology is applicable.

Laser cut acrylic and laser cut wood for advertising

In the advertising making industry, laser cut acrylic and laser cut wood are the main materials of signboards and decorations.

Using a CO2 laser cutting machine can cut various graphics on wood, bamboo, MDF, double-color board, leather, and other materials. And it can also engrave exquisite patterns and text on non-metal materials to make laser cut acrylic crafts and gifts.

Now in the advertising industry, laser cut acrylic boards and laser cut wood signs are very popular. Through laser processing, the laser cut wood also has the effect of color deepening. And the laser cut acrylic have smooth edges, no need for further polishing or flushing.

Laser cut fabric for clothing processing

The laser cut fabric has appeared in clothing processing and many fashion shows. We can use a CO2 laser cutter to cut and engrave any complex patterns in the leather and clothing industry.

Laser cut wood furniture

Laser cut wood furniture have exquisite and unique patterns and styles on various bamboo and wooden furniture decorations. The cutting depth by the CO2 laser cutting machine is generally not deep, within 5mm. The laser cut wood has the effect of being slightly burnt, matching wood background, and shows a primitive artistic beauty. A laser cut wood lamp not only has a beautiful appearance and also presents fantastic light and shadow effect.

Laser cut image crafts

CO2 laser cutting machine can cut and engrave lifelike images on wood, acrylic, and crystal materials. Laser cut acrylic image is unique and exquisite, and very difficult to wear off, and can be permanent.

Laser cut foam for the modeling industry

The laser cutting machine can cut foam and wood materials for the modeling industry. It can also carve on cylindrical and spherical foam materials to meet the individual needs of clients.

CO2 laser cutting machines suitable for non-metal material processing

Laser cut steel building decorations

The fiber laser cutting machine can cut stainless steel, carbon steel, and aluminum alloys.

In the building decorations, we often see the laser cut metal doors and windows and laser cut steel curtain walls.

These laser cut metal decorations have unique and delicate patterns and styles, beautifying the environment.

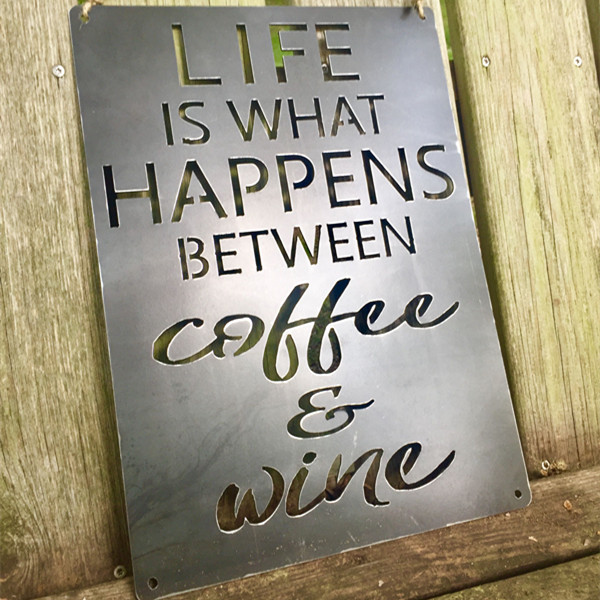

Laser cut metal signs

Stainless steel, titanium, and copper are good materials for making laser cut metal signs.

And laser cut steel can be made into steel letters and signs for advertising and decoration.

And these laser cut metal letters have the most direct publicity effect in showing the image of the store and transmitting brand information.

There is also laser cut acrylic in the printing and packaging industry, laser cut metal in electronics, and laser cut steel in medical industries.

Recommended fiber laser cutting machines

Characteristics of laser cut processing

- High precision

The positioning accuracy of laser cut is 0.05mm, and the repeated positioning accuracy is 0.02mm.

- Narrow cutting seam

The laser beam is a very fine and small spot to cut the workpiece, forming a very narrow cutting seam.

- Good cutting quality: non-contact cutting

The laser cut edge is almost free from the heat affection of the laser. And there is basically no thermal deformation of the workpiece. The cutting surface has no burrs and the incision is neat. And the hole position after laser cut process is precise, and no secondary processing is required.

- No damage to the workpiece

The laser cut head will not contact the surface of the material to ensure that the workpiece is not scratched.

- Not affected by the hardness of the material

The fiber laser cutting machine can process steel plates, stainless steel, aluminum alloy plates, and hard alloys. No matter what the hardness, it can be cut without deformation.

- Free from the limitation of the workpiece shapes

The laser cutting machine has good flexibility, can process any design graphics, and cut pipes and other irregular shapes.

- Material and cost saving

The users can use the computer program to design cutting graphics according to the shape of the board. The laser cutting machine makes full use of the workpiece to maximize the utilization of materials and saves production costs.

- Shorten the new product manufacturing cycle

The laser cutting machine has a fast cutting speed and does not require molds. It greatly shortens the new product manufacturing cycle and improves production efficiency.

Plasma Cutting Applications

Generally, plasma cutting is for cutting various carbon steel, stainless steel, and non-ferrous metal plates. And CNC plasma cutting machines are suitable for rough machining of machinery. Therefore, people commonly use plasma in cutting metal sheets in lots of machinery manufacturing industries.

From the perspective of applicable industries, the application scope of CNC plasma cutting machines mainly includes the following aspects.

Plasma cutting for steel structure engineering

CNC plasma cut technology can mainly meet the processing needs of steel structure processing. It can also cut large and complex steel structures, shells, boxes, and light metal parts in some high-tech industries.

Plasma cutting for machinery manufacturing

The bus body frame is mostly made through the cutting and welding of metal stamping parts and metal sheets. Comparing to flame cutting, plasma cut processing has the advantages of flexible operation, small cutting deformation, and better cutting quality. Using plasma in the bus manufacturing industry can bring good economic benefits.

Plasma cutting for bus manufacturing

CNC plasma cutting machines are very suitable for the manufacturing and maintenance of various machinery and metal structure. And using a plasma machine can complete multiple metal procedures on one machine, for example, metal cutting, opening, and chamfering.

Characteristics of plasma cutting

Plasma cutting is more applicable to cut the metal sheet with a thickness of more than 6mm and lower cutting precision. Although the cutting accuracy is not as high as laser cut, plasma cut technology is faster and better than flame cutting. Especially when cutting ordinary carbon steel sheets, the plasma cut speed reaches 5-6 times that of the oxygen cutting method.

Moreover, the cutting surface is relatively smooth, thermal deformation is smaller, and the heat affect zone is less than flame cutting. Plasma cutting is not limited to cutting carbon plates, stainless steel, copper-aluminum materials, and nickel-titanium metals can be competent.

Tips for using laser cutting and plasma cutting machines

Laser cutting

The laser will cause some damage to the eyes of the operator during use. The operator of the laser cutting machine should take protective measures and wear special protective glasses.

Plasma cutting

Before operating CNC plasma cutting machines, the operator must wear insulated shoes, insulated gloves, and protective glasses. It also needs to connect CNC plasma cutting machines reliably to the ground wire.

Conclusion

In summary, plasma cutting is generally applicable to rough machining of machinery with lower precision cutting requirements. Comparing to the plasma, laser cut processing has higher precision, smaller heat affect zone, and cutting seam, and wider applications. And the fiber laser cutting machine is more suitable for cutting sheet metal with high precision requirements. There is also the CO2 laser cutting machine for cutting and engraving non-metal materials.

At present, the precision requirements for cutting metal materials in various industries are increasing. With the development of laser cutting machines, high-power laser cutting machines have emerged in an endless stream in recent years. And the current laser cut thickness has exceeded 100mm. The advantages of laser cut technology are becoming increasingly obvious. And laser cutting machine will give play to its cutting advantages in more and more industries.