1. What are the types of bending machines?

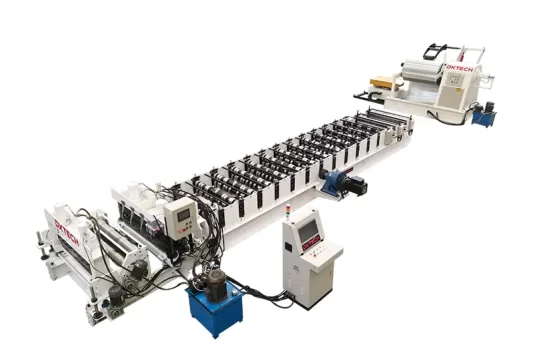

The bending machine is divided into three types: manual bending machine, hydraulic bending machine, and CNC bending machine. Manual bending machine is divided into mechanical manual bending machine and electric manual bending machine. According to the synchronous mode, the hydraulic bending machine can be divided into mechanical synchronous bending machine, torsion axis synchronous bending machine, machine-hydraulic synchronous bending machine, and electro-hydraulic synchronous CNC bending machine.

According to the movement mode, the hydraulic bending machine can be divided into an up-moving type and a down-moving type. The down-moving type is when the workbench and the workpiece on the workbench move upward together, and the slider does not move. At present, it is relatively rare in the domestic market, and most of them are up-moving. The workpiece does not move, and the slider moves downward. According to the control mode, it can be divided into ordinary hydraulic sheet metal bending machine, economical CNC bending machine, and electro-hydraulic synchronous CNC bending machine.

2. Introduction to the function of the bending machine

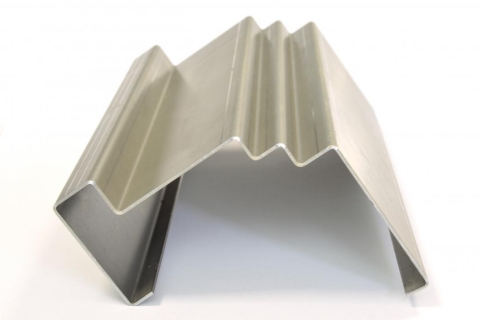

The bending machine is a kind of forging machinery. Its main function is to perform sheet metal processing on sheets, especially large sheets. By matching various molds, sheets can be bent, stretched, Rounded, punched, etc., and widely used in light industry, aviation, shipbuilding, metallurgy, instrumentation, electrical appliances, stainless steel products, steel structure construction, and decoration industries.

The bending machine includes a bracket, a workbench, and a clamping plate. The workbench is placed on the bracket. The workbench is composed of a base and a pressure plate. The base is connected to the clamping plate through a hinge. The base is composed of a seat shell, a coil, and a cover. In the depression of the seat shell, the top of the depression is covered with a cover plate.

When in use, the wire is energized to the coil, and after energization, an attractive force is generated on the pressure plate, to realize the clamping of the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and it can also process workpieces with side walls. The bending machine can meet the needs of various workpieces by replacing the bending machine mold.

The hydraulic bending machine adopts a steel plate welding structure; vibration aging eliminates stress, and the frame has good rigidity and stability; it works smoothly, is safe and reliable, and is easy to operate; it achieves the ideal bending effect through coordinated control of the electrical and hydraulic systems.

3. Main components and structure of the machine

1. Slider part: The slider part of the hydraulic bending machine is composed of a slider, an oil cylinder, and an automatic stop material fine-tuning structure. The left and right oil cylinders are fixed on the frame, and the piston (rod) drives the slider to move up and down through hydraulic pressure.

2. The workbench is composed of a movable workbench and a vertical plate, which are processed by a large CNC milling and boring machine.

3. Synchronization system: This machine is composed of a torsion shaft and arm to form an automatic synchronization device, with a simple structure, stable and reliable performance, and high synchronization accuracy. The automatic stop is regulated by the motor and the ESA system displays the value.

4. Stopper Automation

5. Outsourced accessories

5.1. Main electrical components: Suzhou Siemens Electric Co., Ltd.;

5.2. Hydraulic parts: Rexroth;

5.3. Sealing ring: Japan Valqua Company;

5.4. Control system: ESA S640

5.5. Main motor: Jiangsu Yingkai Motor Company.

5.6. Oil pump: American Sunny

5.7. Mold material: T10# steel overall heat treatment, quenching, and tempering.