Many customers who are interested in fiber laser cutting machines, especially those beginners, are very concerned about the fiber laser cutter cost. After all, the investment of fiber laser cutting machines is a little expensive. Therefore, you need to know not only whether the machine is running, but more importantly, whether the cost of the fiber laser cutter machine is proportional to the benefits it brings. So how to calculate the total cost of a fiber laser cutting machine?

I. Purchase Cost

There are many types of fiber laser cutting machines, including metal sheet fiber laser cutter, fiber laser cutting machine for metal tube, dual-purpose fiber laser machine for metal tube& sheet cutting, automatic fiber laser coiling machine, fiber laser cutter machine with exchange platform, etc.

In addition, with the increase in demand for fiber laser cutting machines, there has been a large price difference in the market. On the one hand, the configuration and function of the fiber laser cutting machine are different; on the other hand, many fiber laser cutting machine manufacturers have set up agents. And the price of the agents is generally a little more expensive than the original price of the machine manufacturer. The above two points cause the difference in the price of fiber laser cutting machines.

The types and prices of common fiber laser cutting machines are as follows:

| Fiber laser cutting machine for metal sheet & tube | $20,000-$60,000 |

| Metal sheet fiber laser cutter | $20,000-$50,000 |

| Metal tube fiber laser cutting machine | $12,000-$30,000 |

| Coil fed fiber laser cutting machine | $45,000-$95,000 |

| Fiber laser cutter with auto loading & unloading | $55,000-$95,000 |

| Sheet Metal fiber laser cutter with exchange platform | $20,000-$50,000 |

| Exchange platform metal sheet & tube fiber laser cutter | $25,000-$60,000 |

| High precision fiber laser cutting machine | $20,000-$60,000 |

II. Cutting Cost

Taking 2000W fiber laser cutting machine cut stainless steel as an example, and then calculate the cost of capital and time.

1. The production cost and approximate time period for cutting 1mm stainless steel for a total of 50,000 meters

50,000 meters ÷ 20 meters/minute ÷ 60 minutes = 41.7 hours ≈ 5 working days

41.7 hours × (27.8 yuan + 70 yuan) ≈ 4078 yuan

2. The production cost and approximate time period for cutting 2mm stainless steel for a total of 50,000 meters

50000 meters ÷ 8.5 meters/minute ÷ 60 minutes = 98 hours ≈ 12 working days

98 hours × (27.8 yuan + 70 yuan) ≈ 9588 yuan

III. Operating Cost

The cost of fiber laser cutting machine mainly includes power consumption, auxiliary gas cost, and the expense of wearing parts.

Take 500W fiber laser cutting machine as an example:

- 1. Power consumption: the hourly power consumption of the 500W fiber laser cutting machine is 6 kWh, and the electricity cost is about 6 yuan/hour (calculated at 1 yuan/kWh).

- 2. Auxiliary gas consumption:

Oxygen: 15 yuan/ bottle for about 1 hour, 15 yuan per hour.

Nitrogen: 320 yuan/ tank for about 12 to 16 hours, 20 yuan per hour.

Compressed air: it can reduce the production cost by about half, but it needs to be equipped with an air compressor.

Please pay attention: Oxygen in the text refers to oxygen bottled; and the nitrogen canned is more cost-effective than bottled nitrogen. Besides, it also saves the operator’s ventilation time and the waste caused by excessive bottled air. In addition, gas prices in different regions will vary.

IV. Maintenance Cost

- Consumption of wearing parts:

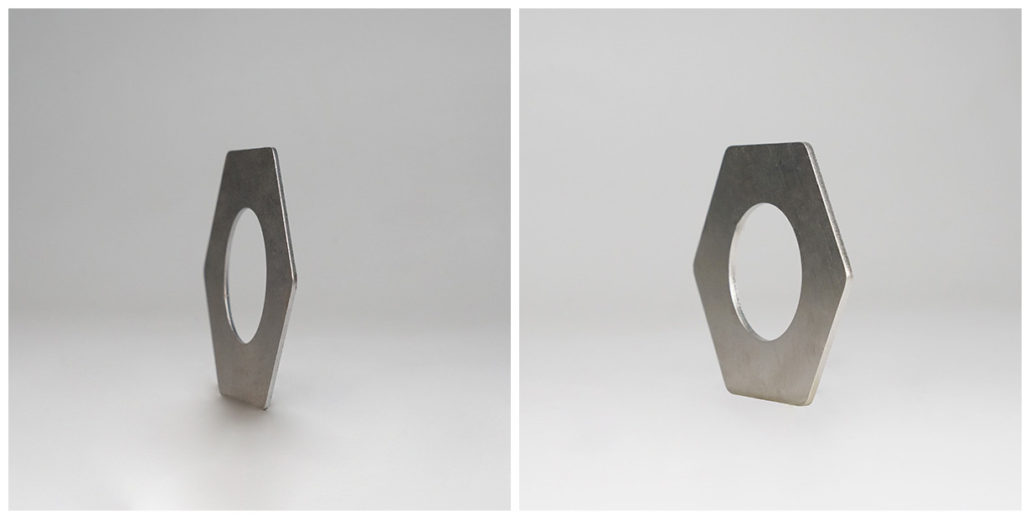

1.Protective lens: more than 300 hours of normal use, the price is 150 yuan/ piece. It spent about 1-2 yuan per hour (if the working environment is good, the use time will be longer). - 2.Nozzle: more than 300 hours of normal use, the price is 50 yuan/ piece, about 0.18 yuan per hour.

- 3.Ceramic ring: more than 7200 hours of normal use, the price is 400 yuan/ piece, about 0.11 yuan per hour.

Word at Last

To sum up, the total operating cost of a fiber laser cutting machine not only includes the price of purchasing the machine itself, but also includes power consumption, labor cost, wearing parts consumption, auxiliary gas consumption, and other cost prices. Therefore, it is not easy to operate a fiber laser cutting machine, which requires a certain amount of financial support. However, its benefits are also proportional. If you are a beginner who wants to work with a fast fiber laser cutter , you can contact us and we will help you choose the most economical and suitable fiber laser cutters of Dxtech.