Inert gas is often used to protect the molten pool during the welding process of laser welding machines. When some materials are welded, surface oxidation may not be considered. However, for most applications, helium, argon, nitrogen, and other gases are often used as protection. The following Let’s take a look at why laser welding machines need shielding gas when welding.

In laser welding, the shielding gas will affect the weld shape, weld quality, weld penetration, and fusion width. In most cases, blowing the shielding gas will have a positive impact on the weld.

Why do laser welding machines need shielding gas during welding?

1. It can protect the focusing lens from metal vapor pollution and the sputtering of liquid droplets

The shielding gas can protect the focusing lens of the laser welding machine from metal vapor pollution and sputtering of liquid droplets, especially in high-power welding, because the ejection becomes very powerful, and it is more necessary to protect the lens at this time.

2. Shielding gas is very effective in dispelling plasma shielding produced by high-power laser welding

The metal vapor absorbs the laser beam and ionizes into a plasma cloud, and the protective gas around the metal vapor is also ionized due to heat. If too much plasma is present, the laser beam is somewhat consumed by the plasma. Plasma exists on the working surface as a second energy, which makes the penetration shallow and the surface of the weld pool widens. The recombination rate of electrons is increased by increasing the three-body collisions of electrons with ions and neutral atoms to reduce the electron density in the plasma. The lighter the neutral atoms, the higher the collision frequency and the higher the recombination rate; on the other hand, only the protective gas with high ionization energy will not increase the electron density due to the ionization of the gas itself.

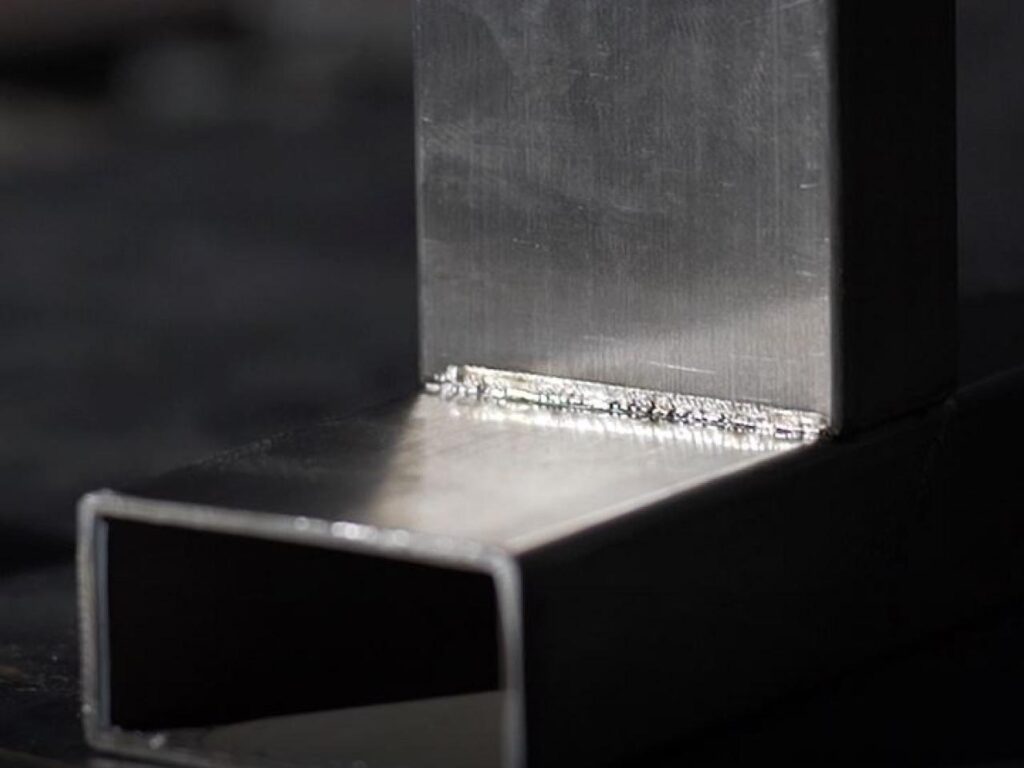

3. The shielding gas can protect the workpiece from oxidation during the welding process

The laser welding machine must use a kind of gas for protection, and the program should be set in such a way that the protective gas is emitted first and then the laser is emitted, to prevent the oxidation of the pulsed laser during continuous processing.

4. The design of the nozzle hole

The shielding gas is injected at a certain pressure through the nozzle to reach the surface of the workpiece. The hydrodynamic shape of the nozzle and the diameter of the outlet are very important. It must be large enough to drive the sprayed shielding gas to cover the welding surface but to effectively protect the lens and prevent metal vapor from contaminating or metal splashing from damaging the lens, the size of the nozzle should also be limited. The flow rate should also be controlled, otherwise, the laminar flow of the shielding gas will become turbulent, and the atmosphere will be involved in the molten pool, eventually forming pores.

Why do laser welding machines need shielding gas during welding? The selection of shielding gas directly affects the quality, efficiency, and cost of welding production. However, due to the diversity of welding materials, the selection of welding gas is also relatively complicated in the actual welding process. It is necessary to comprehensively consider welding materials, welding methods, and welding positions. As well as the required welding effect, a more suitable welding gas can be selected through the welding test to achieve better welding results.