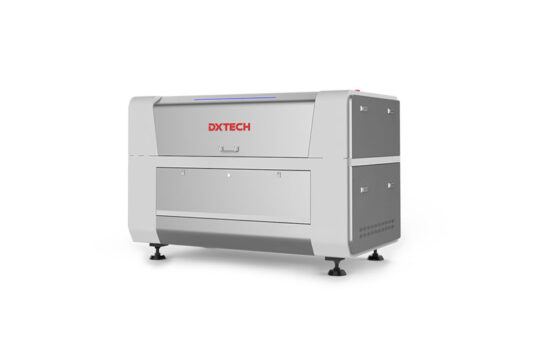

CO2 Laser Engraver

The CO2 laser engraving machine is an engraver using carbon dioxide laser technology. This type of laser engraving machine is a general-purpose model. It adopts the back-focusing method and has the advantages of small size and high integration.

The CO2 laser engraving machine boasts the advantages, such as diverse application materials, long working life, low cost of use, good processing effect, convenient and adjustable output power, maintenance-free, simple operation.

CO2 laser engraving machine is suitable for engraving of most non-metallic materials, such as paper, plastic, label paper, leather cloth, ceramics, resin plastic, bamboo wood, PCB board, crystal, horn, organic glass, marble, cloth, rubber, plastic, and other non-metallic materials.

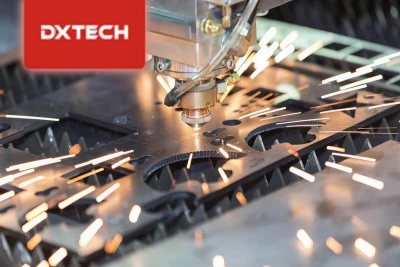

According to the advantages of high energy density, strong operation, a wide range of processing materials, smooth cutting edges without burrs, no polishing, no noise, no dust, high processing speed, high precision, less waste, high efficiency, co2 laser engraving has become the best choice for all industries.

Technical parameters

|

Brand |

DXTECH |

|

Laser type |

Enclosed CO2 laser tube |

|

Cooling mode |

Water cooling |

|

Driving system |

Stepper |

|

Power |

30-200W |

|

Engraving speed |

About 0--60 m/min; |

|

Accuracy of positioning |

<0.01mm |

|

Working voltage |

AC100-220V±10% |

|

Working temperature |

0-45℃ |

|

Operating humidity |

5-95% |

|

Minimum shaping letters |

English 1*1mm |

|

Supportive graphic format |

BMP, PLT, HPGL, DST and AI |

Specifications

| Brand | DXTECH | ||

|---|---|---|---|

| Application | Laser Engraving | ||

| Applicable Material | Non-metal materials like glass, wood, MDF, acrylic, plastic, rubber, paper and fabric, etc. | ||

| Laser Source | CO2 laser | ||

| Laser Tube | Sealed CO2 laser tube | ||

| Working Area | 110mm*110mm, 300mm*200mm, 400mm*600mm, 600*900mm, 1300*900mm, 1600*1000mm, 1300mm*2500mm or as requested | ||

| Laser Power | 50W/60W/80W/90W/100W/130w/150W | ||

| Working Table | Aluminum blade or honeycomb shape | ||

| Engraving Speed | 0-60000mm/min | ||

| Engraving Depth | 0-5mm | ||

| Minimum Shaping Letters | English 1x 1mm | ||

| Rrepeated Positioning Accuracy | ±0.05mm | ||

| Accuracy of Positioning | ±0.02mm | ||

| Working Voltage | 110V/220V 50Hz/60Hz | ||

| Driving System | Stepper | ||

| Operating Temperature | 0-45℃ | ||

| Operating Humidity | 5-95% | ||

| Cooling Mode | Water cooling and protection system | ||

| Control Software | DSP control system | ||

| Compatible Software | corelDRAW, AutoCAD, Photoshop | ||

| Supportive Graphic Format | BMP, HPGL (PLT), JPEG, GIF, TIFF, PCS, TGA, DST and DXP | ||

All things you should know about CO2 laser engravers

Brief introduction:

CO2 engraver is an engraving machine using carbon dioxide laser technology for cutting or engraving non-metallic materials mostly. It mainly consists of the CO2 laser, the engraving platform and cover, and the control system. People also call the CO2 laser engraver as a CO2 laser engraving machine, CO2 laser marking machine, and CO2 laser engraving system. This type of laser machine has a wide range of applications, small sizes, and a high degree of integration.

As a kind of CNC laser engraver, it has user-friendly laser engraved gifts that are easy to operate and can create precise, high-speed engraving process. This kind of CNC laser engravers also has different types like others. Portable laser engraver also knew as handheld laser engraver is designed for engraving immovable, enormous objects. Mini laser engraver is made for small objects. Other types of CNC laser engraver like DIY laser engraver can allow people to create their innovative products.

Sometimes, the manufacturers subdivide the CO2 engraver according to different materials. For example, there are CO2 glass engraving machine, CO2 engraver for metal and CO2 engraver for wood, etc.

1. Equipped with the blade table, it can be used to process rigid advertising boards such as acrylic and MDF.

2. With a wide range of applications, it widely used in the advertising industry handicraft production, decoration, rubber plate furniture, and other industries.

3. With the features of compact design and simple structure, it is more convenient to operate.

4. Imported high-precision ball screws and guides are adopted for stable driving and high working accuracy.

The best laser engraver can deal with various materials, even some metal sheets. It also has precise CO2 engraving technology and high-efficient working speed.

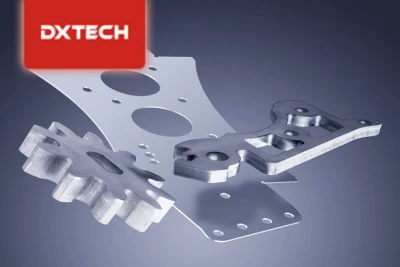

Applicable materials:

The CO2 engraver is suitable for marking and engraving on most of the non-metallic materials. Such materials include paper packaging, plastic products, and leather, cloth, glass, ceramic, resin and plastics, bamboo and wood, etc.

DXTECH’s CO2 engraver can engrave LOGO, letters, designs, QR codes, serial numbers, and symbols on these non-metallic materials.

It can also complete the high-precision cutting of acrylic boards and MDF in advertising, models, and plastic processing.

The engraving effect of the CO2 engraver has the features of being precise, clear, and wear-resistant.

Applicable industries:

CO2 engraving machine is widely used in the advertising processing industry, gifts & crafts processing, clothing, and shoe industries. It is also applicable in the packaging industry, product marking industry, and decoration industry.

As the CO2 engraver can deal with various materials at an affordable price, it has become the first choice to make laser engraved gifts. Lots of laser engraved gifts such as laser engraved photo has become popular in customers.

DXTECH can also supply the home laser engravers to meet the needs of individual users.

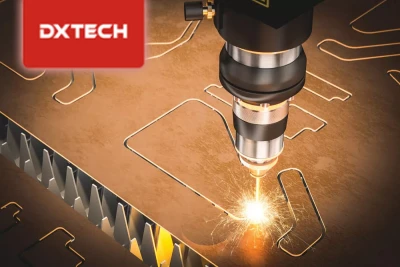

The CO2 engraver uses the gas laser with the infrared light band. CO2 gas is charged into the high-voltage discharge tube to generate glow discharge so that the gas molecules release laser. And after the amplification, the laser energy forms a laser beam for material processing. The laser beam irradiates on the materials on the working table through the transmission of the lens.

And under the strong thermal energy of the laser, the temperature of the materials increases sharply. The working point melts or vaporizes rapidly due to high temperatures. With the moving route of the laser head, the machine completes the processing and achieves the effect of engraving.

The CO2 engraver connects with the computer through the data cable, and the supporting software is installed on the computer. The users can input the designs or graphic patterns into the control system of the CO2 engraving machine through software.

CO2 laser processing technology belongs to non-contact processing. It will not directly contact with the materials during processing. Therefore, this laser machine will not change the inner structure of the materials. It relies on the high density of laser energy and has strong laser engraving operation performance.

In comparison with the traditional mechanical engraving technology, the CO2 laser engraver has a quicker working speed and higher efficiency. It can engrave more complicated computer graphics and can cut vertical letters with more accuracy. The acrylic letters or boards after processing have no need for further polishing treatment. CO2 engraver can also engrave or cut glass, leather, and rubber foam boards. Generally, the users need not fix the materials for engraving especially.

The best laser engraver must have the best laser engraver software that helps operators create a more precise and efficient engraving process.

Laser tube

This laser tube has a variety of power 15W-80W for users to choose, and its working service life is up to 1800 hours. With the advantages of long service life, complete functions, fast processing speed, high processing quality, high processing efficiency, stable performance, and low maintenance costs, it has been chosen by many users.

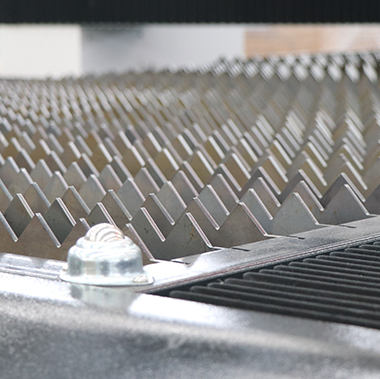

Blade table

The blade table of the laser engraver has a relatively large gap, and the contact surface with the material is relatively small, and the blade can adjust the density, which is very suitable for rigid advertising plates such as acrylic and MDF, reducing the diffuse reflection of the laser on the platform phenomenon to avoid leaving marks on the bottom of the material.

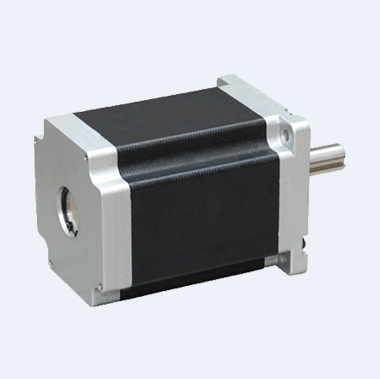

Motor

This motor is known for its stability and speed, high-cost performance, and is the world's largest sales brand. It has the characteristics of high speed and stable performance. The rated speed can reach 3000 rpm, which can ensure high speed and high efficiency while ensuring stable operation.

The users must accept training and follow the instructions of the laser engraving machine for safe operation. The following gives major steps of using the CO2 laser engraving machine for your reference.

· Check before starting up

- Check if the power supply is normal and whether the cooling water tank is filled with the soft water. And whether the circulating water pump and water inlet and outlet pipes are normal or not.

- To see if the emergency stop button of the laser is pressed down. Check whether there are any sundries on and in the CO2 laser engraving machine.

- Check if the lens is clean, if any dirt, the users should not use the lens until cleaning it.

- Inspect the machine parts, to confirm there is nothing but a work-piece on the working table.

- Check if the air pump works normally.

· Starting up

- Turn on the power supply of the control cabinet, and switch on the circulating water pump. Confirm there is water flowing out of the outlet normally.

- Switch on the dust removal fan.

- Turn on the power supply of the laser to wait for the system to turn into a normal working state (about 30 seconds).

· Engraving process

- Place the materials for processing on the working table.

- Adjust the height of the laser to the appropriate position.

- Turn on the computer and open the engraving software.

- Open the file for laser engraving in the software, and turn into the status of ready for engraving.

- Adjust the starting coordinates of the laser head, and press ENTER to confirm the origin of coordinates.

- Press the key “TEST”, the laser head will draw the outline border of the processing area. Observe whether the area is suitable for material processing. If not, adjust it to the suitable one.

- Close the cover of the CO2 laser engraving machine. Press the key “START” to start the processing.

·Turning off the machine

- After the completion of processing, there will be a prompt tone. The operators can open the cover and take out the work-piece.

- Switch off the laser, and 1 minute later, turn off the circulating water pump.

- Clean the inside of the CO2 laser machine.

- Switch off the power source of the control cabinet. And turn off the computer.

- Turn off the general supply, and make records in details after the completion of processing each time. The records include the working hours, current and engraving parameters in the software.

Note: The operators shall protect themselves from directly contacting the laser beam. This is to avoid damage to their bodies.

Regrading of the use of CO2 laser engraving machine, the manufacturers of laser engraving machines will generally provide training service. And the customers do not need to learn laser engraving machine knowledge additionally.

The users shall maintain the CO2 laser engravers regularly. Therefore, it can increase the service life, save costs, and create greater benefits.

1. Cleaning of the outer surface

After the CO2 laser engraver completes the processing every time, the users must clean the environment at first. It needs to clean the ground and the laser machine. The parts for cleaning include the outside surface of the control cabinet, the cover of the laser system, and the working table.

2. Maintenance of the cooling water system

For the maintenance of the cooling water system, it needs to regularly check the temperature and volume of the cooling water. The users need to replace the water if its temperature is too high. And they must add new water if the volume is not enough. This system can use either the soft water or the distilled water.

It also needs to check whether there is any leakage at the joint of each water pipe. If yes, tighten such a place to avoid leakage. The users shall check the rubber gaskets carefully. If the gaskets do not work anymore, it needs to replace it with a new one.

3. Cleaning of the optical system

The inside optical devices belong to the design of the enclosed type, and need not cleaning generally. If necessary, the users can clean the lens according to the following methods.

Use the paper specially for cleaning the camera lens to soak a little ethyl alcohol. And then, wipe up the optical lens.

It needs to pay great attention during the process of wiping up. And it shall not clean vigorously, in order to avoid damaging the surface of the optical elements.

4. Regular maintenance of the driving belts

There are several synchronous belts in the driving system of the CO2 laser engraving machine. If the belts re too tight or too loose, it will affect the working quality of the machine. Therefore, after a period of use, it needs to adjust the tension screw of the belts. It is forbidden to use edible oil when applying lubricating oil to the track. Industrial lubricating oil is required.

While using the CO2 laser engraving machine, the users need to pay attention to many things, especially some wearing parts. We must maintain the parts with care, including the use of special cleaning agents. This is to make our operation become easier and produce our products with higher precision. Therefore, we must also maintain the laser machine carefully.

There are various kinds of laser engravers on the market, so how to choose the most suitable one? The buyers cannot only consider the laser engraver cost. The following points may help you.

1. Firstly, the users need to confirm in which industry they plan to do the processing business.

As mentioned above, the CO2 laser engraver is mainly for the processing of non-metal products. And the most typical industries are the advertising industry.

The users may also do a market survey, and find out what machine others in the same industry are using.

2. Secondly, the users consider the size of the materials for laser engraving.

This is about the choice of the size of the working table of the laser engraving machine. But the users should notice that the large size of the machine is not necessarily good. Because the large-size equipment is of course more expensive.

If the work-piece is small, and the working table is large, the laser output some laser machines may become unstable. It will result in irregular depths on the same working table. Therefore, it is better to choose the most appropriate working table in combination with the size of the work-piece.

3. Power of laser tube

Some customers may look for a 20w laser engraver or 40w laser engraver, and some may want to buy laser engravers with a higher power, such as 40w laser engraver and 100w laser engraver. Actually, no matter it is a 20w, 40w, or 100w laser engraver, it is suitable for marking and engraving on non-metallic materials. However, the power is different, the marking speed is also different. The higher the power, the faster the speed.

Therefore, the users can select appropriate laser tube wattage according to the material for laser engraving and their budget.

4. Good reputation and after-sales service:

The quality of the after-sales service will directly affect production efficiency. If the machine has a failure and the users cannot solve it, it will directly stop production. Thus, the after-sales service maintenance is very important.

Therefore, when customers choose laser engraving machine products, they must actively analyze the market. While buying the laser engraver, they can figure out which manufacturers supply good-quality machines and have a good reputation. Some buyers may want to find the used laser engraver. But there is generally no after-sales service nor technical support for the used laser engravers. It is recommended to buy a new one. The laser engraver cost is not high, and the buyers can recover the cost very soon.

Nowadays, finding a responsible laser engraver manufacturers can help customers save time and cost. They provide the best CO2 laser engraver for sale, and also the CO2 laser engraving cutting machine to satisfy the various requirements of their customers.

DXTECH laser has a long development history, and the standardized management systems and manufacturing procedures. Its products get praised and welcomed by clients all over the world. And DXTECH can provide the complete set of laser engraver kit and owns the after-sales department for the oversea countries. Even for the buyers of home laser engravers, DXTECH offers technical support and serves them in the same way. The professional technical engineers will give you a reply and solve your problems timely.