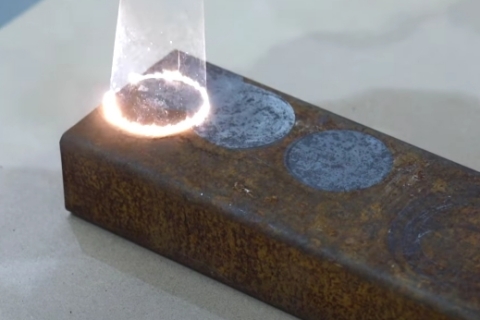

A laser cleaning machine is a kind of cleaning equipment that uses the high energy, high focus, and high directionality of a laser beam to instantly vaporize or peel off dirt, rust, coatings, etc. on the surface of objects. Laser cleaning machines have the characteristics of non-abrasive, non-contact, no thermal effects, and are suitable for cleaning objects of various materials. They are considered to be the most reliable and effective solution. At the same time, laser cleaning machines can solve problems that traditional cleaning methods cannot solve, such as cleaning complex-shaped objects or cleaning toxic and harmful substances.

According to the mechanism of laser interaction with objects attached to the surface, laser cleaning machines can be divided into the following four types:

1. Laser dry cleaning method

That is, pulse laser direct radiation is used for decontamination. This method is suitable for situations where the requirements for matrix damage are low, or the laser absorption coefficients of the matrix and attachments are significantly different.

2. Laser + liquid film method

That is, a liquid film is first deposited on the surface of the substrate, and then laser radiation is used to remove the contamination. This method is suitable for situations where the requirements for matrix damage are high, or the difference in laser absorption coefficient between the matrix and the attachment is small.

3. Laser + inert gas method

That is, while the laser irradiates, inert gas is blown to the surface of the substrate. When the dirt is peeled off from the surface, it will be blown away from the surface immediately to avoid re-contamination and oxidation of the surface. This method is suitable for situations where the requirements for substrate damage are high, or when the attachments are heated and will produce toxic or harmful substances.

4. Use the laser to loosen dirt and then clean it with non-corrosive chemical methods.

This method is suitable for cleaning special materials such as cultural relics.

DXTECH is a comprehensive enterprise integrating R&D, production, and sales. It has been deeply involved in the laser product industry for many years and has many years of export experience. It has an in-depth understanding of customer needs and uses its rich knowledge of industrial laser machines and products to help customers choose the most suitable and cost-effective The highest machine that can achieve the processing effects they want in the metal or non-metal industry.

DXTECH laser cleaning machine is a new generation of industrial surface cleaning laser systems. It uses advanced laser light sources, laser optical scanners, and control systems to meet the requirements of metal surface cleaning processes.

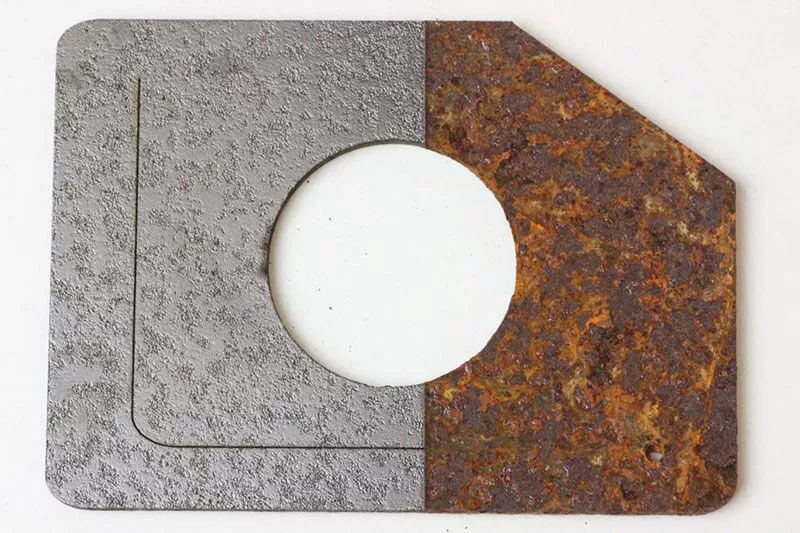

DXTECH laser cleaning machine adopts efficient and green cleaning technology. Compared with chemical cleaning methods, it does not require any chemicals or cleaning fluids. And it has many features such as no grinding, no stress, no consumables, etc. Therefore, it is favored by various industries. This machine uses laser cleaning, which is non-abrasive and non-contact. DXTECH laser cleaning machine is not only suitable for cleaning organic pollutants but also for cleaning inorganic substances, including metal rust, metal particles, dust, etc. It can achieve rust removal, paint removal, oil removal, cultural relic restoration, glue removal, and coating removal. and plating removal. In addition, it is also suitable for cleaning processes such as rust, thin paint layers, light oil stains, or technical, rust removal on polished metal surfaces.

DXTECH’s laser cleaning machine is a device that uses the pulse laser dry cleaning method and has the following advantages:

1. High cleaning efficiency, laser parameters can be adjusted according to different materials and dirt.

2. The cleaning quality is good and can achieve cleaning results without damage, residue, and secondary pollution.

3. It has a wide cleaning range and can be applied to objects of various materials and shapes such as metals, non-metals, composite materials, etc.

4. Low cleaning cost, no need to use chemical solvents and consumables, and only consumes a small amount of electricity.

5. The cleaning operation is simple and can be used handheld or fixed. It is equipped with a professional control system and display interface.

DXTECH’s laser cleaning machines have been widely used in aviation, automobile, shipbuilding, mold, chemical, electric power, food, and other industries, providing users with efficient, environmentally friendly, and safe cleaning solutions. If you have laser cleaning needs, please contact DXTECH; we will provide professional consultation and services.