As we all know, laser cutting machine is playing an essential role in the metal processing industry. Applying the right laser cutting machine to the project is a question that all metal fabricators should think about. The laser pipe cutting machine is an advanced automatic laser cutting machine for metal pipe cutting. Different from the common metal sheet laser cutting machine, metal pipe cutting machine realizes the three-dimensional processing for metal pipes. As the metal pipe processing industry has strict requirements on processing efficiency and accuracy, the emergence of laser pipe cutting machines is an effective boost. If you are engaged in metal pipe cutting or want to buy a pipe laser cutter, this article will provide you with comprehensive guidance.

What Is Laser Pipe Cutting Machine?

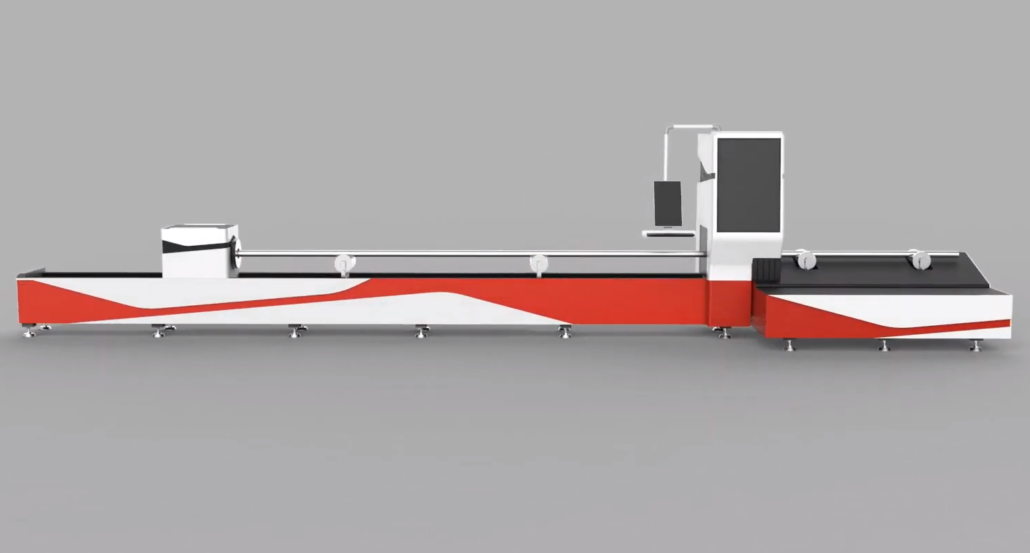

Laser pipe cutting machine, as the name suggests, is a kind of laser cutting machine for metal pipes. As shown in the picture, the machine has a long and narrow frame structure. And the machine is equipped with metal pipe clamping devices to clamp and rotate metal pipes at different angles.

In the cutting of metal pipes, fiber laser is the main source of energy. The manufacturing process of the fiber laser pipe cutting machine has been very mature. And the fiber laser pipe cutting machine is playing an outstanding performance in cutting various types of metal pipes.

You may ask: ”What kind of metal pipes can be cut by laser?” A common laser pipe cutter can cut various pipes, such as round pipes, square pipes, rectangular pipes and so on. There are also some metal pipe cutting machines that are designed to process special shapes of metal pipes, such as triangular pipes, U-shaped pipes, etc.

Why Use Laser for Metal Pipe Cutting?

The metal pipe processing companies may consider why they should use laser pipe cutting machines instead of other tools. This is because the traditional metal pipe cutting methods, such as milling, grinding wheel cutting, and circular saw cutting, are inefficient and pollute the environment. The laser pipe cutter adopts eco-friendly laser technology. It has the following unique advantages:

1. Multiple Processing Functions

Laser pipe cutting machine can not only perform simple vertical cutting but also beveling, slotting, carving and punching. No matter how you need to process metal pipes, the machine can almost do it. The multifunctional cutting benefits from the intelligent CNC software. Under the control of the CNC software, the machine can automatically complete complex forms of cutting according to the instructions.

2. High Cutting Precision

Same as the working principle of a common metal plate laser cutting machine, the laser pipe cutting machine uses a laser beam to vaporize the material to achieve the cutting purpose. The narrow laser beam will leave a narrow and smooth slit on the metal pipe. And the slit is clean and free of burrs. This can easily achieve the required precision and edge finish requirements.

3. Fast Cutting Speed

Under the control of the CNC software, the rotating device and the laser head can achieve perfect coordination and deliver fast cutting speed. In square pipe processing, the rotating device rotates the metal pipe to an appropriate angle, and then the laser head starts to work. After one side is cut, the rotating device immediately rotates and then the laser head conducts the cut again. In round pipe cutting, the rotating device and laser head work together to process curved surfaces while rotating the pipe.

4. Suitable for Integrated Batch Operation

Laser cutting metal pipes can easily complete the clamping and positioning of several meters long pipes, which makes batch processing possible. According to the processing needs of customers, many manufacturers can configure the pipe laser cutting machine with automatic loading and unloading functions to realize integrated production. In addition, many metal sheet & pipe laser cutting machines have also been manufactured to realize the dual function of cutting metal plates and metal pipes. Therefore, one machine can meet multiple requirements of customers.

5. Save Materials and Reduce Processing Costs

The initial investment of a laser pipe cutting machine is expensive. However, for those companies that have been engaged in metal pipe processing for a long time, the machine can improve the processing accuracy and product qualification rate. And the companies can reduce material waste and processing costs in the long run.

Laser Pipe Cutting Applications

Metal pipes such as stainless steel pipes are mainly used to transport domestic water, sewage, industrial water and petroleum, so the laser pipe cutting machine can show its versatility in water supply and drainage, sewage treatment, heating, electricity, petroleum, etc. In addition, metal pipes are also widely used in the construction industry, sports and fitness, medical, vehicle and machinery manufacturing industries, and the laser cutting machine also plays an important role in these industries.

Laser Pipe Cutting Machine in Water/Oil Delivering Industry

In water and oil delivering industries, laser pipe cutting machines play an important role. The diameter of pipelines for transporting water or oil is generally relatively large and not easy to be cut. However, the tightness and strength of the joints between the pipelines are extremely high. And there is no leakage will be allowed. Laser cutting can create flat cutting edges to achieve seamless connection and high-precision pipeline laying. Furthermore, compared with traditional knife cutting, laser cutting will not cause stress on the cutting surface. The metal pipe has high strength and the quality is improved.

Laser Pipe Cutting Machine in Construction Industry

The construction industry has high requirements for the stability and cutting accuracy of steel structures. The laser can process steel efficiently and the processing accuracy can fully meet the requirements. Moreover, the mechanical metal parts required by the construction industry also need to comply with strict safety regulations. The pipe laser cutting machine can achieve high-precision processing in processing steel pipes so that the metal pipe fittings can be accurately aligned during assembly. And it is very suitable for batch processing. The machining dimension error of parts of the same model is extremely small.

Laser Pipe Cutting Machine in Sports & Fitness Industry

As people pay more and more attention to physical health, the demand for various sporting goods and fitness equipment is increasing rapidly. Fitness equipment in the sports industry requires a lot of metal pipes. The metal pipes used in fitness equipment are mainly steel pipes. Laser has a very good cutting effect in cutting steel pipes and has been widely used in the processing of various fitness equipment. Compared with traditional cutting methods, laser pipe cutting machines have higher cutting quality. And it has a faster cutting speed (8 to 20 times faster). Also, laser cutting does not need to consume a lot of molds, which can help fitness equipment manufacturers reduce production costs.

Laser Pipe Cutting Machine in Medical Industry

With the spread of COVID-19, all kinds of medical equipment are in urgent need. How to quickly produce medical equipment to meet the needs of hospitals is an urgent matter for medical equipment manufacturers. Choosing laser pipe cutting machines can increase the efficiency of metal pipe cutting. And it realizes efficient processing of metal pipes used in medical equipment such as hospital beds, carts, and shortens the production cycle, which will help treat the patients and control the epidemic.

Laser Pipe Cutting Machine in Vehicle and Machinery Manufacturing Industry

In the manufacturing of agricultural machinery and other machinery, many mechanical structures need metal pipes. The ordinary cutting methods cannot achieve good processing accuracy. Laser can efficiently cut metal pipes and the accuracy can reach the millimeter level. This greatly improves the quality of the machines and makes them play a better role in various fields. Besides, in the auto industry, laser pipe cutting machines can perform high-precision and high-efficiency processing of various metal pipe parts, such as exhaust pipes, instrument panel brackets, etc.

Precautions for Using Laser Pipe Cutting Machine

When using the laser pipe cutting machine, there are two precautions for users to pay attention to:

When the metal pipe is being cut, both of the two sides are within the irradiation angle of the laser. Therefore, when cutting one side of the metal pipe, pay attention to the other side. Check whether it will be affected by the laser radiation. This can be done by adjusting the appropriate laser power, cutting speed and appropriate laser focus.

When cutting metal pipes, sometimes some metal scraps usually fall into the inside of the pipe. For users who have high requirements on the inside of the metal pipe, pretreatment is a necessary step. Pre-paint the inside of the pipe with a splash-proof agent to prevent the molten metal from sticking to the inside of the pipe. After processing, clean the inside of the metal pipe in time to achieve a clean cut.

How to Buy A Laser Pipe Cutting Machine

If you need to buy a laser pipe cutting machine to meet your metal pipe cutting needs, then you can buy it according to the following steps.

Step One: Look for the Laser Machine Manufacturer

The first step is to clarify your processing needs and choose a reliable laser machine manufacturer. Consider the shape, length range and diameter range of the metal pipes that you want to process. Then, look for a suitable laser machine manufacturer that can produce this kind of machine. When looking for a laser machine manufacturer, check whether the company can provide comprehensive after-sales service. Also, the machine needs to have at least a one-year quality warranty. And it would be better if you inspect the factory firstly and check the manufacturer’s actual production capacity.

Step Two: Customize the Laser Machine

The next step is to communicate the needs with the laser machine manufacturer. The salesperson will guide you to select the configuration, customize the machine, and pay the deposit. Generally, this kind of large machine requires you to choose the appropriate configuration according to your budget and processing needs. The configuration includes machine table size, laser source, motor, drive, control system, guide rail, etc. Then, your machine starts to be produced. After the machine is ready, you need to pay the balance, and then the manufacturer will contact the freight company to ship the machine to your place. For international machine transactions, the manufacturer will provide you with the procedures and documents needed for machine import.

Step Three: Installation and Adjustment

The last step is to check the machine parts and assemble the machine. After receiving the machine, you need to check whether each part of the machine is in good condition. Then, test the machine’s performance after assembling it to check whether it is operating normally. If any machine parts are damaged, or you need technical guidance to teach you to assemble and operate the machine, the manufacturer will provide guidance and training.

Recommend Best Laser Pipe Cutting Machines

With the profound laser experience, DXTECH would like to recommend the following two machines for your reference.

Best-selling Laser Pipe Cutting Machine From DXTECH

This best-selling laser pipe cutting machine is professional equipment for cutting metal pipes. It is manufactured with world-class parts that have high quality, stable operation, and long service life. This machine can cut metal pipes from 3 to 9 meters long. The chuck can hold metal pipes of different diameters. In addition, if you have specific requirements for the processing length and processing diameter, DXTECH can customize the machine.

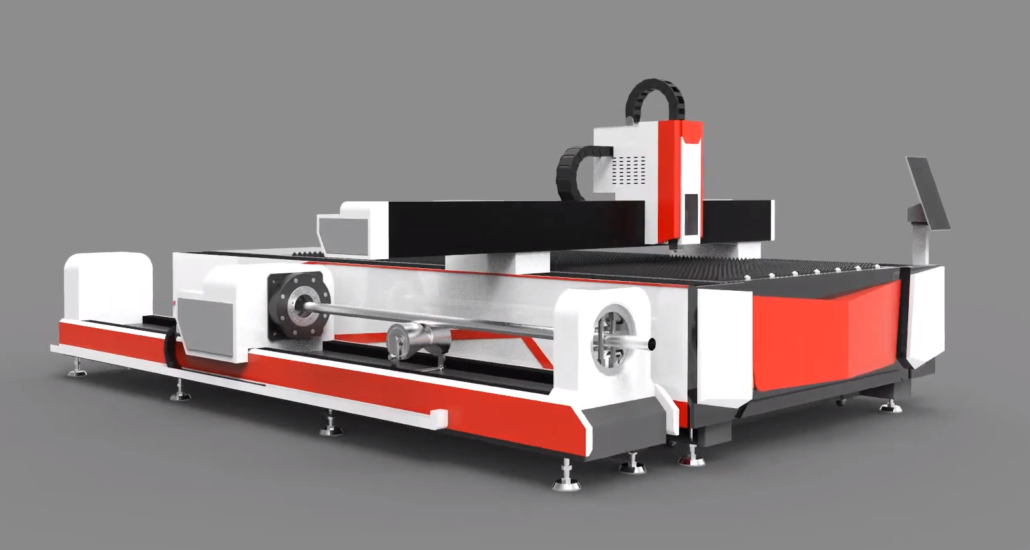

Multifunctional Pipe & Sheet Laser Cutting Machine

This metal pipe and sheet laser cutting machine can process both metal pipes and metal plates. It can meet the diverse processing needs of users. The machine adopts a heavy-duty cast iron bed with very high strength, which can guarantee no deformation within 20 years. Moreover, the machine’s aviation aluminum beam and high-precision guide rails can ensure good processing precision.

Conclusion

Laser pipe cutting machine brings a lot of benefits to the metal pipe fabricators. Compared to the traditional metal pipe cutting methods, the laser pipe cutting machine makes faster cuts and better results. What’s more, it can achieve multiple processing effects on the pipes. Besides, it does not need any molds and greatly saves production costs.

Are you looking for a better cutting machine for cutting metal pipes? If so, a laser pipe cutting machine is your ideal choice. Applying a laser pipe cutting machine to your project will bring you higher productivity and a faster return on investment. If you want to know more info about laser pipe cutting machine, you can contact us at any time.