Laser welding is an efficient and precise welding method that uses a high-energy-density laser beam as a heat source. Laser welding is one of the important aspects of laser material processing. It is mainly used for welding thin wall materials and low-speed welding. The welding process is of the heat conduction type. That is, the laser radiation heats the surface of the workpiece, and the heat on the surface diffuses to the inside through heat conduction. Due to its unique advantages, it has been successfully applied in the precise welding of micro and small parts. So how does a laser welder work?

The working principle of THE laser welder :

Focusing of the laser beam

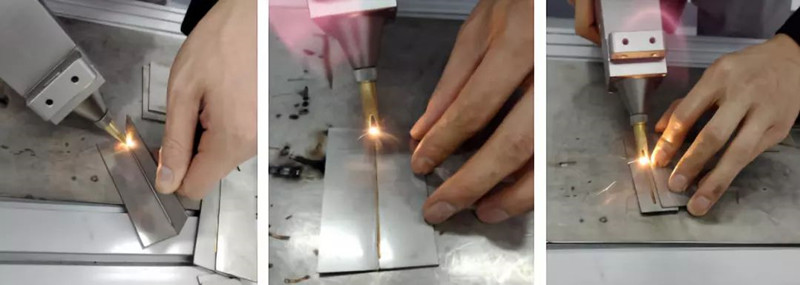

The laser beam generated by the laser is focused by optical elements such as lenses or mirrors. The laser beam then focuses the energy on the welding point.

Heat Conduction

When the laser beam is irradiated on the surface of the workpiece, the laser energy will be absorbed and converted into heat energy. Through heat conduction, it is gradually transferred along the metal conducting part of the welded joint, raising its temperature.

melting and mixing

When the metal surface is exposed to a sufficiently high temperature, the metal begins to melt and form a molten pool. Under the action of the laser beam, the molten pool diffuses and mixes rapidly to reach the connection of the metal joints.

cooling and solidification

Once the laser beam is stopped, the molten pool gradually cools and forms a welded joint during solidification. During solidification, the metal molecules rearrange to form a strong welded joint.

Conclusion

The process of laser welding consists of four parts: optical focusing, heat conduction, melting, and cooling. It has the advantages of fast welding speed and a small heat-affected zone. Therefore, it is widely used in welding tasks of various metal materials in industrial production, such as automobile manufacturing, electronic devices, aerospace, and other fields. However, in actual use, the operator also needs to select the appropriate laser parameters and welding technology according to specific needs to achieve a good welding effect. Hope this information helps you!

DXTECH hopes that everyone can buy real high-tech equipment at a more favorable price. Of course, we can also customize it according to customer’s requirements, and try our best to meet the needs of domestic and foreign customers. If you want to get more information, please don’t hesitate to follow us.