Laser Cutting Machine

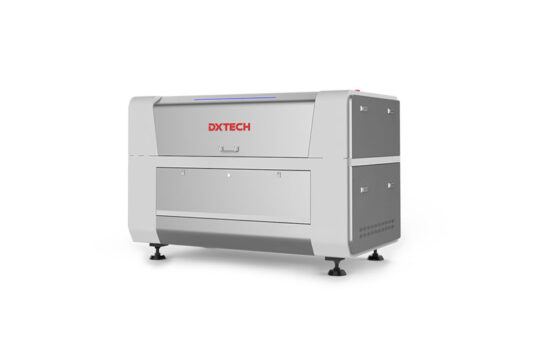

As one of the leading laser cutting machine manufacturers or laser cutters manufacturers, DXTECH has always upheld the laser cut ideas of Do the Best Within the scope of ability, and provides various affordable and efficient laser cutter projects for our customers.

show more

Classified in terms of laser cutting materials, DXTECH can offer the following laser cutters, such as acrylic laser cutter or acrylic cutting machine, wood laser cutter or laser wood cutter, laser metal cutting machine or metal laser cutting machine, laser paper cutter, sheet metal laser cutter.

Plus, from the perspective of function and types of laser cutters, DXTECH can provide the CNC laser machine (CNC laser cutter). Specifically speaking, the CNC laser machines include the following types: CO2 laser cutter, fiber laser cutting machine, home laser cutter or home laser cutting machine, desktop laser cutter, hobby laser cutter (hobby laser cutting machine), DIY laser cutter.

In addition to the admirable laser cutters, DXTECH also provides the considerate and comprehensive laser cutting service, relatively cost-effective laser cutter price, various laser cutter for sale, and devise the laser cutter project as your needs.

show less

Specifications

| Brand | DXTECH | ||

|---|---|---|---|

| Application | LASER CUTTING | ||

| Laser Type | Fiber Laser/CO2 Laser | ||

| Applicable Material | Fiber Laser: All kinds of metal materials CO2 Laser: Non-metallic materials |

||

| Working Area | 3000*1500mm, 4000*1500mm 4000*2000mm, 6000*2000mm |

||

| Laser Power | Fiber Laser | 1000W/1500W/2000W/3000W/4000W/6000W/8000W/12000W | |

| CO2 Laser | 100W/150W/180W/200W/500W/1500W/2000W | ||

| Max Operating Speed | 100m/min | ||

| Repeated Positioning Accuracy | ±0.01mm | ||

| Working Voltage | 380V/50Hz | ||

| Operating Temperature | 5-45℃ | ||

| Operating Humidity | 5-95% (Free of Condensed Water ) | ||

| Cooling Mode | Industry water chiller | ||

| Cutting thickness | Detailed in the following cutting thickness | ||

| Certification | ISO9001, CE, FDA, ROHS | ||

Cutting Thickness of Fiber

| 1000W | Mild Steel | 6.30mm |

|---|---|---|

| Stainless Steel | 3.10mm | |

| Aluminum | 3.10mm | |

| Copper | 1.50mm | |

| Brass | 2.0mm | |

| 2000W | Mild Steel | 9.50mm |

| Stainless Steel | 4.80mm | |

| Aluminum | 4.80mm | |

| Copper | 2.50mm | |

| Brass | 3.10mm | |

| 3000W | Mild Steel | 12.70mm |

| Stainless Steel | 6.30mm | |

| Aluminum | 6.30mm | |

| Copper | 4.10mm | |

| Brass | 4.80mm |

Cutting Thickness of CO2 Laser (mm)

| 60W | Acrylic | 3-10mm |

|---|---|---|

| Plywood | 5mm | |

| 80W | Acrylic | 3-30mm |

| Plywood | 5-12mm | |

| MDF | 6mm | |

| 100W | Acrylic | 3-30mm |

| Plywood | 5-12mm | |

| MDF | 6-15mm | |

| Sponge | 2mm | |

| 130W | Acrylic | 3-30mm |

| Plywood | 5-12mm | |

| MDF | 6-15mm | |

| Sponge | 2mm |

The laser cutting machine (aka laser cutter) works by emitting a laser beam. Such a laser beam of high power density is formed through the optical path system. The laser beam lights to the surface of the workpiece, so that the workpiece reaches the melting point or boiling point. Moreover, the high-pressure gas coaxial with the beam will blow away the molten or vaporized metal. With the movement of the relative position of the beam and the workpiece, the material will turn into a slit. By doing so, the purpose of cutting will achieve.

Types

According to different lasers, the CNC laser cutter for sale mainly includes fiber laser cutters and co2 laser cutter.

According to different processing materials, it comes into various types. These types cover metal laser cutters, non-metal laser cutters, carbon steel laser cutters, paper laser cutters, acrylic laser cutter or acrylic cutting machine, wood laser cutter or laser wood cutter, laser metal cutter or metal laser cutting machine, laser paper cutter, sheet metal laser cutter, wood cutting printer.

There are many types of laser cutters. And any types of CNC laser cutting machines, we can provide for you to meet your different processing requirements.

Fiber laser cutting machine and CO2 laser cutting machine is the main types of CNC laser cutting machine.

- Fiber laser cutting machine is a kind of industrial laser cutter which also known as metal laser cutting machine. It can cut different types of metal such as stainless steel, iron plate. It has powerful laser support that penetrate the metal sheet and result smooth, high-finished edge. Therefore, it is widely used to cut complex object like tube, so it also be known as tube laser cutting machine.

- CO2 laser cutting machine is another kind of industrial laser cutter. It can cut various non-metal materials like acrylic, wood, plastic. As it can cut acrylic with perfect cutting result, it is also be known as acrylic laser cutting machine. Laser cutting manufacturers use this kind of industrial laser cutter provide various laser cutting services. You can design your laser cutting design online, and the manufacturer will provide the final cutting result.

Features

Our laser cutter boasts many characteristics, such as high precision, fast cutting, unlimited cutting patterns, smooth cutting, small heat-affected zone of cutting, small deformation of plates, narrow cutting slits, low processing cost. The laser cutting machine will gradually improve or replace the traditional metal cutting process equipment.

Applications

Laser cutters are widely applicable in many industries, such as sheet metal processing, advertising sign production, high and low voltage electrical cabinet production, mechanical parts, electrical parts, glasses industry, spring sheets, circuit boards, electric kettle, medical microelectronics, hardware, knife measuring tools.

People use small laser cutter for small business or cutting at home for their unique laser cutting design. With the flexibility, and using conveneint, small laser cutter has become more and more popular as personal or industrial laser cutter.

Materials

With the efficient cutting method, laser cutting machine can deal with different kinds of laser cutting materials. Some of them can also be cut by other methods, but laser cutting still are the best choice for the manufacturers because of its smooth, high finished cutting result.

- Laser cut acrylic:

Nowadays, acrylic has become a kind of material which is widely used in various industries, and laser cut acrylic is more and more common in the cutting industry. Laser cut acrylic can make products like laser cut acrylic signs, laser cut jewelry, laser cut earrings, etc.

- Laser cut paper:

As the improvement of environmental consciousness, there has more and more paper packing in packaging industry. Laser cutting technology achieves complex laser cut patterns on paper. Laser cut paper products widely used as packaging products, or paper decorations.

- Laser cut steel:

The laser beam of high power density focuses its energy on a certain point to provide an efficient cutting way, even for steel. Laser catting machine can deal with many kinds of steel materials, and the types of laser cut steel includes carbon steel, alloy steel, stainless steel.

- Laser cut MDF:

Medium-density fibreboard (MDF) is made by breaking down wood residuals into wood fibers and combining it with wax and resin binder, and formed though high temperature and pressure. The final result is an aesthetic light beige panel. Using laser cut MDF achieve a high-finished edge, so most cutting manufacturers prefer this cutting method.

- Laser cut aluminum:

Other metal materials like aluminum can also be cut by laser. Using laser cut aluminum is quicker and more efficient than other cutting methods, and the final cutting products have better performance. Aluminum as a kind of laser cutting material is very suitable for laser cutting, it reacts with the laser beam and creates satisfying products for customers.

- Laser cut fabric:

Laser cutting technology is widely used in light industries like the clothing industry. People mainly use laser cut fabric, because the laser cutting is productive and efficient, and the laser cut fabric is precise with a high-finished degree, which can be used to make a clothing directly.

- Laser cut glass:

Glass is a very fragile material for cutting. Laser cutting is a cutting technology that can be used at glass cutting. Using laser cut glass is precise, the laser beam cuts along the laser cutting pattern you design, and the heat temperatures will preserve the glass from breaking.

- Laser cut plywood:

Plywood is a high strength laminated sheet made from Birch timber. This kind of material is suitable to cut by laser, and often bonded with MR glue line, also be known as laser cut plywood in the industry.

- Laser cut plastic:

Using laser cut plastic is very common in manufacturing industry. It is convenient to create a complex laser cutting pattern on a plastic objects with a smooth, elegant cutting result. Nowadays more and more plastic manufacturers prefer this kind cutting method to create their products.

- Laser cut leather:

You may heard some conventional cutting method to make leather products like handbags, leather shoes. Nowadays, using laser cut leather is gradually replace the traditional method because of its efficient and high-finished result. The laser cut leather is not only more precise but also elegant and modern.

- Laser cut wood panels:

Using laser cut wood panels is preferred by decoration manufacturers. With the high-speed and efficient cutting technology, manufacturers can cut various laser cutting patterns as their own laser cutting designs.

- Laser cut foam:

Laser cutting technology nearly can deal with all types of foam, and using CO2 laser cut foam is efficient and common. During the laser cutting foam process, the laser machine creates a laser beam that heats the material directly in its path, making it vaporize. It can create a high-finished edge which is preferred by manufacturers.

- Laser cut vinyl:

Using laser cut vinyl is more professional, and it is not suitable to achieve by people themselves. Finding an experienced laser cutting company is a good choice.

Products

Laser cut box: Most manufacturers prefer using laser cut box because of their high-speed of cutting and precise shape making.

Laser cut cards: The popular laser cut cards include laser cut invitation, laser cut business card, etc. Laser cut invitation should have a delicate pattern design.

Laser cut signs: Nowadays, laser cut signs are popular as presents, logo decoration, etc. The types of laser cut signs include laser cut metal signs, laser cut acrylic sings, laser cut font and laser cut plastic signs.

Laser cut lamp: We have the cutting machine that achieves a laser cut lamp.

Laser cut jewelry: Laser cut jewelry is popular in the youth, and using laser cut jewelry achieves the complex jewelry design efficiently.

Laser cut earrings: Laser cut earring has become the most popular amount of laser cut jewelry. The youth prefer the delicate design and lightweight of the decoration.

Laser cut stencils: Laser cut stencils are widely used in the printing industry like printing screens.

Laser cut models: Laser cutting technology can cut the components of laser cut models, and the common type of cutting models are wooden laser cut models.

Laser cut clock: Laser cutting technology is also used to cut the components of furniture, laser cut clock is a popular kind of it.

Laser cut puzzle: Cutting a puzzle is a tough task, and laser cutting technology can help you finish it. The laser cut puzzle is easier to be completed.

Laser cut cardboard: Laser cut cardboard has wide usage such as making models and decorations.

Laser cut name: Laser cut name is similar to laser cut font and laser cut jewelry that using laser cutting technology to create letters.

When operating a CNC laser cutter, have you ever wondered how such a laser cutter near me works; how does such a laser cutter near me produce the nearly flawless produces? Today, let's together unveil the mysterious cover of this "huge guy". The laser cutting machine is to focus the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point. And then the high-pressure gas coaxial with the beam blows away the molten or vaporized metal.

As the relative position of the beam and the workpiece moves, the material will eventually form a slit. Finally, it achieves the purpose of cutting. Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting patterns. Besides that, it also has the features of automatic typesetting, saving materials, smooth cuts, and low processing costs. It will gradually replace the traditional metal cutting process equipment.

Creating a laser cutting work needs to import laser cut files into the CNC laser cutting machine. Manufacturers according to their demands design the laser cut files, and the laser cut files determine the quality of laser cutter projects. What kind of laser cut products you want to make, what the laser cut ideas you create, and what kind of laser cut patterns you want to cut, all of laser cutting design will be demonstrated through the laser cut files.

The CNC laser cutting machine for paper involves precision processing. Therefore, the users must pay attention to operate according to instructions and maintain the machine regularly. So that the users can increase the service life of the machine, save costs, and create greater benefits.

· Before starting up the machine

- Comply with the general safety operation regulations of laser cutting machines. Start the laser strictly in accordance with the start-upprocedures.

- The operators must accept training,and befamiliar with the structure and performance of the laser machine. And they also need to master the knowledge of the operating system.

- The operators must wear labor protection articles according to regulations.Andthey must also wear protective glasses that meet the regulations near the laser beam. Keep the fire extinguisher within easy reach.

- Do not cutmaterial before makingclear whether it can be irradiated or heated by a laser. This is to avoid the potential danger of smoke and vapor.

· During the operation

- 1. Whenstarting upthe laser machine, the operators shall not leave the post or ask others to operate without authorization. If it is necessary to leave, stop the machine, or cut off the power switch.

- 2. After turning on the machine, the operators shall manually start the machine in the X and Y directions at low speed.This is to check whether there is any abnormality.

- 3.After inputting the new cutting program, carry out the test run firstly,and check its operation.

- 4.When working, pay attention to observe the operation of the machine.This is to avoid accidents caused by the cutting machine going out of the effective stroke range or

- 5. If anyabnormality during the cutting process, theoperators shall shut down the machine immediately. And it needs to eliminate the fault or report to the supervisor.

· After the operation

- Turn off the laser when not in operation.Do not place the paper, cloth, or other flammable materials near the unprotected laser beam.

- 2. Keep the laser, the machine, and the surrounding area clean, orderly, and free of oil pollution.And place the work-piece, plates, and waste materials as required.

- 3. The users shall carry out the maintenanceregularlyin accordance with regulations and procedures.

· Daily maintenance

- Clean the residue at the bottom of the nozzle before the operation every day.

2. Adjust the center to ensure that the laser is in the center of the nozzle.And observe the spot to ensure the best quality of the laser. - Make sure the stable air pressure for cutting.

- Blow the dust on the surface of the machine with an air gun before getting off work every day.And clean up the waste inside the drawer.

· Weekly maintenance

- 1.Blow the inside of the power box withan air gun. The dust may cause poor contact with electronic components.

2. Clean the filter screen in front of the water tank. And blow the dust inside. The dust may cause insufficient heat dissipation. - Remove the protective lens and focus lens.And wipe them gently with the lens wiping clothsoaked with absolute alcohol. The dirty lens will affect the paper cutting quality.

- 4.Use the cloth to clean the dust and oil stain on the surface ofthe cutting head. And it is better to wipe with a little alcohol.

- The computer anti-virusshould be done timely. It’s better to use a special USB disk to input

· Maintenance every half a month

- Replace the pure water or distilled water in the water tank.And wipe the dirt in the water tank with a clean cloth. Clean the filter element in the water tank and the filter, which should be replaced once a month.

- Wipe the guide rail of the screw rod clean and apply lubricating oil.And move back and forth at low speed until the oil completely penetrates into it.

· Monthly maintenance

- Check the screws of the screw rod base and motor base beside the two shafts.And check whether the coupling screws are loose. The loose screws will affect cutting accuracy and increase the wear and tear.

2. Check whether the screw on the back of the cutting head is loose and tighten it. The loose screws will affect the cutting effect.

Are you looking forward to a DIY laser cutter or coming up with an idea to buy an affordable laser cutter? Now, here comes a piece of good news, you are in the right place for a hobby laser cutting machine. DXTECH not only provides laser cutter for sale but also offers the considerate laser cutting service. Here are six tips to help you better buy a suitable laser cutter with a reasonable laser cutting machine price.

First, users must first consider the materials they need to process and the scope of business needs. It includes factors such as the thickness of the material to be cut and the type of material to be cut.

Then determine the power size and table size of the equipment. The power of laser cutting machines currently on the market ranges from 500W to 10000W. Manufacturers of the general size of the workbench can customize it according to customer needs.

Second, choose a fiber laser cutting machine manufacturer. After confirming the needs, we can go to the market to find out the performance of the fiber laser cutter. Because a competent laser cutting machine manufacturer can come up with the suitable laser cutting designs, laser cutter project, laser cutter ideas, laser cutter patterns, and provide various laser cutter for sale. And we can also go to the counterparts who have bought the fiber laser cutting machine to have a look at the basic parameters of the CNC laser cutting machine.

Then choose several manufacturers with reasonable laser cutter prices and preferential prices for preliminary communication and proofing. Later, we can conduct on-site inspections, machine prices, machine training, payment methods, after-sales service, etc.

Third, choose the size of the laser power. The laser is the core component of the cutting machine. When choosing the performance of the cutting machine, the size of the laser power is very important. For example, we often cut metal sheets below 6 mm, so we can choose 500W-700W cutting machines to meet production needs. If we cut the material over 6 mm, we need to consider a more powerful machine. This is of great help to the cost control of the enterprise.

Fourth, choose the core components of the fiber laser cutting machine. Some important parts of the laser cutting machine, we also need to pay great attention when purchasing. Especially for laser generators, laser cutting heads, servo motors, guide rails, water chillers, etc., it is necessary to distinguish whether they are domestic or imported. These components directly affect the cutting speed and accuracy of the fiber laser cutting machine.

Fifth, the quality of equipment and the stability of use are also very important metrics. Now the product development cycle is short, the update is faster and faster, the product diversity, sample trial production, mass production is more. How to complete customer orders with quality and quantity is the arduous task facing manufacturers.

So choose stable performance processing equipment is the premise and foundation. We try our best to choose brands that have a high market share, a sound after-sales service system, and many after-sales service outlets. You can't just buy low-quality products without after-sales service just because you are greedy for temporary low prices. This will have a huge impact on the company.

Sixth, after-sales service. The after-sales service of each manufacturer is very different, and the warranty period is also uneven. In terms of after-sales service, we can provide customers with effective daily maintenance programs. And we also have a professional training system for machines and laser software to help customers get started as soon as possible.

Types of laser cutting machine

Laser cutter for sale has different types, such as metal laser cutting machine, wood laser cutter, CNC laser cutting ma chine, fiber laser cutting machine, acrylic laser cutting machine, home laser cutter machine. Laser cutting machine price is different because of the different types.

On the other hand, these kind of laser cutting machine for sale is also known as cutter, such as metal laser cutter, CNC laser cutter, DIY laser cutter, CO2 laser cutter, desktop laser cutter, home laser cutter, fiber laser cutter, 3D laser cutter, and small laser cutter.

Laser cutting service

Except find the laser cutter for sale, building a cooperation relationship with a responsible laser cutting manufacturer will help you create a successful laser cutting business. And there are some types of laser cutting service which was provided by most laser cutting manufacturers.

- Online laser cutting:

Finding a suitable laser cutting near me is a bit difficult? Don’t be worried, most laser cutting manufacturers provide various laser cutting services including online laser cutting. This kind of service supports its customers send laser cut files to the manufacturers, then you can select the materials, and the manufacturers produce the part according to your requirements, finally deliver the parts to you. Nowadays, online laser cutting has become a popular cutting production method to cooperate with foreign cutting companies.

- Sheet metal laser cutting:

Laser cutting manufacturers can provide all kinds of metal laser cutting services for their customers, and the sheet metal laser cutting is one of the main cutting services.

- Fiber laser cutting:

Fiber laser is a kind of laser that is mainly used to cut, mark, and engrave various types of metals. Choosing the manufacturers who have fiber laser cutting service is versatile for various customers.

- Tube laser cutting:

Some laser cutting manufacturers provide special object cutting services like tube laser cutting services. They have a suitable cutting machine to deal with these special cutting object according to the requirements of their customers.

- Stainless steel laser cutting:

Stainless steel is a kind of laser cutting materials and provides stainless steel laser cutting is also included in the scope of the service of most laser cutting manufacturers.