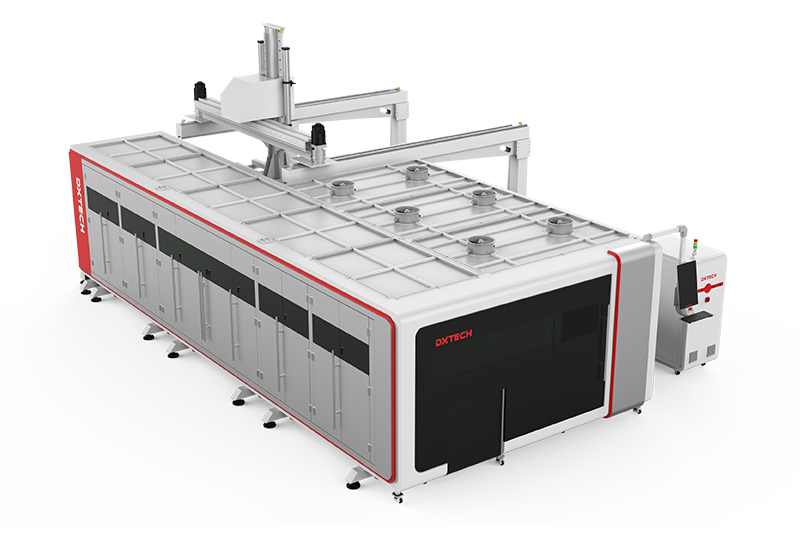

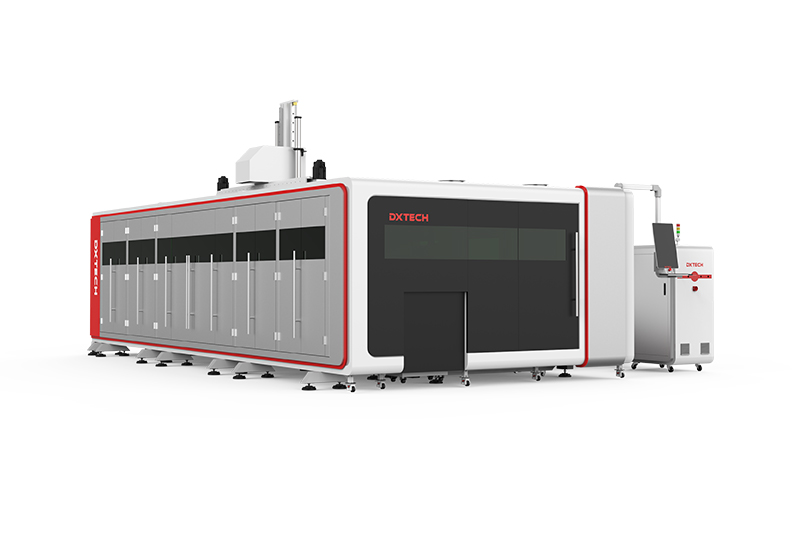

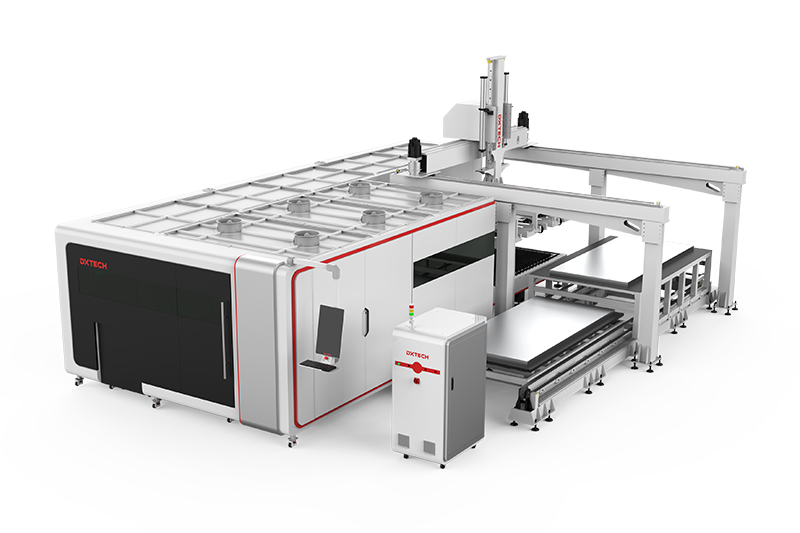

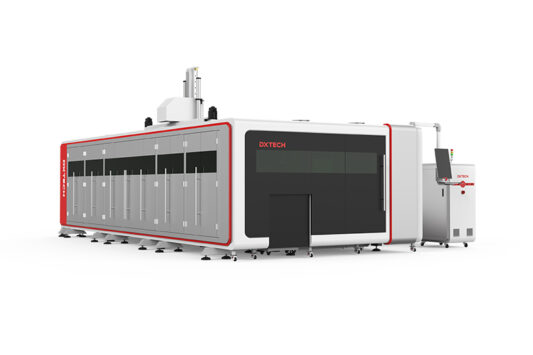

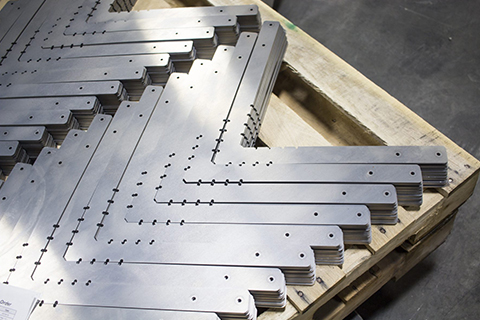

This all cover exchange table sheet and tube laser cutter has multiple functions. It can not only process metal sheets, but also process round metal tubes, square metal pipes, etc. The exchange platform greatly saves the loading and unloading time and improves the overall efficiency. With the advanced imported machine parts adopted, this machine has excellent processing performance and long working life. It can help metal fabricators improve processing efficiency and product quality. This multifunctional machine has wide applications in shipbuilding, auto manufacturing, engineering machinery, agricultural machinery, metal tools manufacturing and other industries.

Advantages

- Low cost: the sheet metal is automatically loaded on the exchange platform, and the finished products are stacked on the pallet. save non-productive duration and lower energy consumption.

- Higher Intelligence: it can accurately measure the metal sheet thickness. And then Sheet metals are automatically loaded to exchange platforms.

- Environmental friendly: With digital operation and safe handling, sheet metals are well protected from scratching and finished products will be at higher quality.

- Higher efficiency: it can serve multiple cutting machines at the same time, making production more efficient. With this advantage, the automatic loading and unloading system will save non-productive duration and lower the energy consumption.

- High precision: it is one of the most popular automatic loading and unloading system of our machine because it can protect sheet metals from scratching with digital operation and safe handling. And the completed products have high quality.

DXTECH Service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Components of Metal Sheet And Tube Fiber Laser Cutter

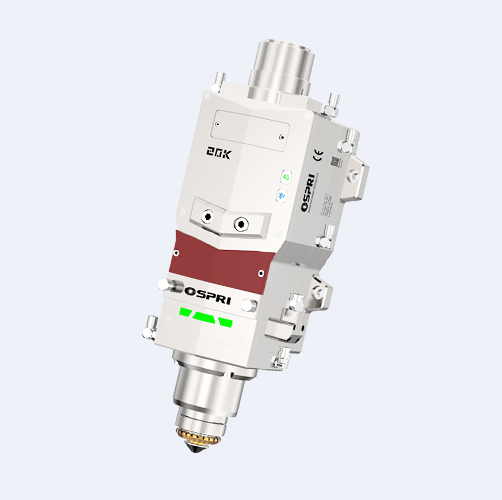

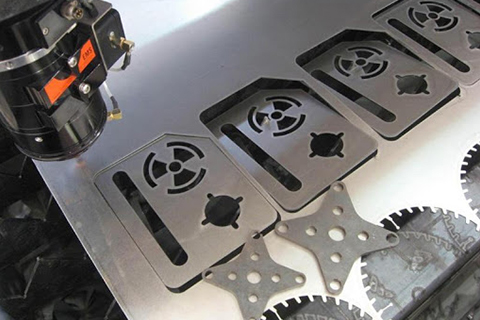

Intelligent focusing laser head

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Aviation aluminum beam

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

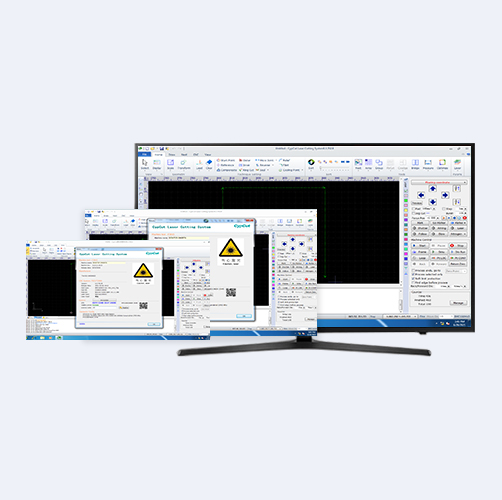

Weihong LS1500/LS3000 Laser Cutting Control System

Weihong laser cutting control system is a software for plane laser cutting. It supports AI, DXF, PLT and international standard G codes generated by Mater Cam, Type3, Wentai, etc.

Except common editing and typesetting functions, it has unique processing sequence browsing and powerful material database to load the specification directly. Besides, operators can control the system through wireless handheld box and Ethernet conveniently.

We provide free proofing service. Welcome to consult.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.