Fiber laser cutting machine is an automatic metal cutting machine that adopts laser technology. As the standard of metal cutting becomes more stringent, fiber laser cutting machines get more and more recognition among metal processing users. And fiber laser cutting has the advantages of non-contact cutting, high efficiency, excellent accuracy, and low operation cost. DXTECH has more than 10 years of experience in the manufacturing of functional fiber laser cutting machines. And till now it has provided a lot of advanced fiber laser cutting machines for various customers. In this article, I summarized the eight best fiber laser cutting machines in 2021. All of these eight fiber laser cutting machines are manufactured with world-class machine parts. The differences are machine size, configuration and processing range. For example, the 1309I fiber laser machine is suitable for small-scale metal cutting. And the 1530 exchange table fiber laser machine is designed for batch metal processing.

Note: At the end of the guide, I listed three steps that you need to consider when buying a fiber laser cutting machine. Please don’t miss that part.

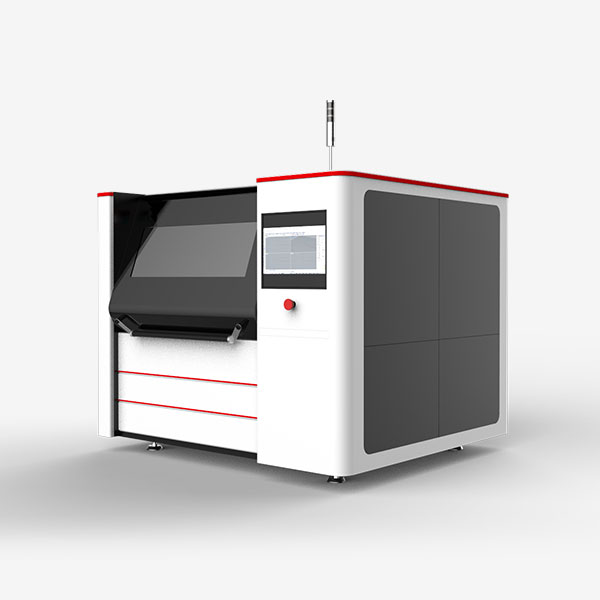

NO 1. DXTECH-1309I: Best Fiber Laser Cutting Machine for Small Business

This DXTECH-1309I fiber laser cutting machine is the first one that I would like to recommend. It is the best laser cutter for small businesses. The operation of this small fiber laser cutting machine is very simple and the price is affordable. If you need a home laser cutter to make some small metal products, this one can be your ideal choice. DXTECH manufactures fiber laser cutters with strict standards to ensure high quality. Although this DXTECH-1309I machine is small in size, it adopts Raycus laser head, Japan servo motor, Germany Schneider and other world-class parts. In addition, this small fiber laser cutting machine adopts a laser protective cover. It can protect the safety of you and your partner.

What’s more, it has excellent cutting performance. The maximum cutting speed can reach 25m/min. Users can complete metal cutting quickly and easily. For metal products designers and artisans, you can use this small fiber laser cutting machine to make exquisite metal jewelry, metal accessories, metal decorations, metal ornaments, metal parts, metal tools and so on. This small fiber laser cutting machine can deal with various metal materials. And it can perform different cutting processes, like flat cutting, drilling, engraving, flying cutting and so on.

Parameters of This Small Fiber Laser Cutting Machine

| Model | DXTECH-1309I |

| Machine Type | Enclosed type |

| Laser Type | Fiber laser |

| Working Area | 1300 mm * 900 mm (can be customized per customer needs) |

| Laser Output Power | 500W/750W/1000W/1500W/2000W (can be customized per customer needs) |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Max Cutting Speed | 25m/min |

| Cutting Thickness | 0-20mm |

| Maximum Acceleration | 1.5G |

| Laser Source Brand | Raycus, Max |

| Working Life of Fiber Module | More than 100,000 hours |

| Control System | Cypcut |

| Servo Motor | Japan Yaskawa / Japan Fuji (optional) |

| Electrical Components | France Schneider |

| Transmission | HIWIN guide rails / PMI guide rails (optional) |

| Reducer | Japan SHIMPO |

| Cooling Mode | Water cooling |

| Certificate | ISO9001, CE, FDA, ROHS |

| Warranty | 1 year |

| Price | $29,000-$45,000 (for reference only) |

| Processing Materials | Stainless steel, mild steel, carbon steel, galvanized steel, aluminum, aluminum alloy, titanium alloy, brass, copper, iron, silicon steel, etc. |

| Applicable Industries | Metal tools, household appliances parts, engineering machinery parts, metal dashboards, heat sinks, gaskets, gears, metal jewelry, metal accessories, metal wall decorations, 2D/3D metal ornaments, metal crafts and gifts, auto parts, metal logos, advertising signs, medals, metal badges, kitchen utensils, etc. |

Five Reasons to Choose This Small Fiber Laser Cutting Machine

- Small footprint. With the compact machine structure, this small laser cutter only takes up a small space. And it is very suitable for small-scale metal processing projects, such as metal jewelry, metal accessories, metal crafts, metal precision parts, etc. It can be the best laser cutter for small businesses.

- High safety and environmental friendly. Equipped with a fully protective cover, this metal laser cutting machine provides intimate protection for the operator from laser radiation. And the working environment is more tidy and clean.

- Wide processing materials and various processing styles. With the top-quality laser head adopted, this small laser cutter has wide applications. It can deal with various metal materials, including carbon steel, stainless steel, galvanized steel, aluminum sheets, aluminum alloy, brass, etc. According to different processing requirements, it can conduct line cutting, flying cutting, engraving, drilling and grooving on metals.

- Long machine service life. The machine is equipped with heavy-duty welded cast iron bed. The cast iron bed has high stability, high tensile strength, and strong chock resistance. It can make the machine run stably without deformation for 20 years.

- High processing speed, high accuracy, and flexible processing patterns. The machine adopts an aviation aluminum beam which is light in weight and has high strength. It can ensure the fast speed, high accuracy of the machine as well as allowing various processing shapes.

NO 2. DXTECH-1530: Best Fiber Laser Cutting Machine for Beginners

For beginners who are new to the metal laser cutting world, a fiber laser with complex functions and complex operations is not a proper choice. It will cost a lot of time and effort for people to learn. DXTECH produced this best entry level laser cutter for beginners. As an entry level laser cutter, it adopts a user-friendly control panel and is very easy to learn even though you have no laser knowledge. And the price is affordable. It is the best entry level laser cutter and is the most cost-effective choice for metal laser cutting beginners. Moreover, it shows excellent cutting performance and can help people open a successful metal machining business. The configuration adopts imported high-quality parts to ensure stable operation and high precision. With this easy-to-learn entry level laser cutter, beginners can quickly master the operation and make beautiful cuts on metals.

Parameters of This Entry Level Fiber Laser Cutting Machine

| Model | DXTECH-1530 |

| Machine Type | Open type |

| Laser Type | Fiber laser |

| Working Size | 1500 mm * 3000 mm (can be customized per customer needs) |

| Laser Power | 1200W (can be customized per customer needs) |

| Position Accuracy | ±0.05mm/m |

| Max Movement Speed | 1200mm/s |

| Max Cutting Speed | 20m/min |

| Cutting Thickness | 0-12mm |

| Power Consumption | ≤12KW |

| Working Voltage | 380V/50Hz |

| Servo Motor | Japan Yaskawa / Japan Fuji (optional) |

| Electrical Components | France Schneider |

| Reducer | Japan SHIMPO |

| Transmission | HIWIN guide rails / PMI guide rails (optional),

Germany VASTUN high precision grinding rack |

| Laser Source Brand | Raycus, Max |

| Working Life of Fiber Module | More than 100,000 hours |

| Warranty Time | 1 year |

| Delivery Time | About 20 days – 30 days |

| Cooling Mode | Water cooling |

| Price | $29,000-$46,000 (for reference only) |

| Processing Materials | Stainless steel, carbon steel, mild steel, galvanized steel, aluminum, aluminum alloy, titanium alloy, brass, copper, iron, silicon steel, etc. |

| Applicable Industries | Electrical cabinets, auto parts, electronic parts, elevator parts, robot manufacturing, aircraft parts, subway metal parts, advertising signs, parking lot signs, display signs, company custom signs, metal decorations, metal crafts and ornaments, metal gifts, metal household items, kitchen countertops, utensils, metal furniture, etc. |

Eight Reasons to Choose This Entry Level Fiber Laser Cutting Machine

- User-friendly control panel. The control panel is very simple to learn and operate. Even beginners can quickly master the basic operation after several hours of learning. This machine can save much training time and training costs for users. It is the best laser cutter for beginners.

- Functional control system. The control system accepts international standard G codes of various software versions. And it includes many common typesetting functions, such as copy, align, rotate, mirror. This functional control system makes the design process easier for beginners.

- High processing speed and quick acceleration. The servo motor is imported from Japan. It has large torque and it greatly ensures the high-speed operation and quick acceleration of the machine.

- No deformation for 20 years. The welded cast iron bed is tempered at a high temperature to eliminate stress and has a strong load-bearing capacity. It ensures the long-time stable operation of the machine.

- Stable processing performance. The aviation aluminum beam has high-stress resistance and high rigidity. The weight is lighter than the ordinary iron beam. This aluminum beam is more stable and can efficiently improve the cutting velocity.

- High processing precision and clean cutting effects. The world-class laser generator releases a high-density laser beam and makes perfect cuts on the metal. The cutting edge has nearly no burr during the normal operation. And there is no need to do secondary processing.

- Wide applications in various metal processing occasions. This machine finds its great popularity in various metal processing fields. It can be used to make metal parts, metal tools, metal advertising signs, metal decorations, kitchenware, metal crafts, etc.

- This is an open type fiber laser cutting machine. The open style makes the loading and unloading more convenient, and it allows the machine to process longer workpieces.

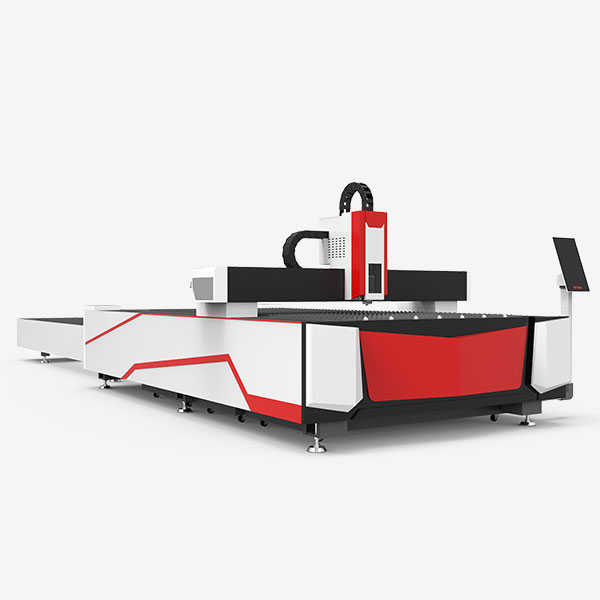

NO 3. DXTECH-1530F: Best Large Format Fiber Laser Cutting Machine

This DXTECH-1530F has a large working size and is the best large format laser cutter for large-scale projects. It has multiple laser powers to select (500W~12000W). The biggest advantage of this large format laser cutter is that it has strong cutting power. This laser cutter finds great popularity in the manufacturing of electric cabinets, automobiles, elevators, robots, aircraft and so on. The laser power can be customized per the specific processing need. This fiber laser cutter has high cutting accuracy and strong cutting power. It can efficiently cut various materials, such as stainless steel, carbon steel, galvanized sheet, aluminum alloy, titanium alloy, silicon steel, etc. Even when cutting thick metal sheets, this large power fiber laser cutter can ensure a smooth cutting surface. You can watch below working demonstration to know the real cutting effect of this large power fiber laser cutting machine cuts on different thickness of metal plates.

Parameters of This Large Format Fiber Laser Cutting Machine

| Model | DXTECH-1530F |

| Machine Type | Open type |

| Laser Type | Fiber laser |

| Working Area | 1500 mm * 3000 mm (can be customized per customer needs) |

| Laser Output Power | 500W-12000W (can be customized per customer needs) |

| Laser Source Brand | Raycus, Max |

| Working Life of Fiber Module | More than 100,000 hours |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Max Cutting Speed | 25m/min |

| Cutting Thickness | 0-30 mm |

| Maximum Acceleration | 1.5G |

| Control System | Cypcut |

| Servo Motor | Japan Yaskawa / Japan Fuji (optional) |

| Electrical Components | France Schneider |

| Transmission | HIWIN guide rails / PMI guide rails (optional) |

| Reducer | Japan SHIMPO |

| Cooling Mode | Water cooling |

| Certificate | ISO9001, CE, FDA, ROHS |

| Warranty | 1 year |

| Price | $48,000-$52,000 (for reference only) |

| Processing Materials | Stainless steel, carbon steel, mild steel, galvanized steel, aluminum, aluminum alloy, titanium alloy, brass, copper, iron, silicon steel, etc. |

| Applicable Industries | Electrical cabinets, auto parts, electronic parts, elevator parts, robot manufacturing, aircraft parts, subway metal parts, advertising signs, parking lot signs, display signs, company custom signs, metal decorations, metal crafts and ornaments, metal gifts, metal household items, kitchen countertops, utensils, metal furniture, etc. |

Six Reasons to Choose This Large Format Fiber Laser Cutting Machine

- High processing precision and no thermal deformation. The high-quality laser generator releases a high-density laser beam and makes smooth cuts on the metal surface. And there is little thermal affected zone and almost no thermal deformation. People don’t need to do any post-processing on the products. What’s more, the laser generator can keep working for a long time. It easily adapts to the industrial continuous production needs.

- Various laser powers for your selection to meet your specific processing needs. According to the characteristics and thickness of the processing material, DXTECH customizes laser power for you. The largest laser power 12,000W can efficiently cut 30 mm thick stainless steel. It is the best large format laser cutter.

- Strong load-bearing capacity. The heavy-duty cast iron bed is about 5 tons and it has good rigidity and strong load-bearing capacity. This guarantees the longevity of the machine.

- The aviation aluminum beam has light weight and good rigidity. It can greatly improve the laser cutting speed of the machine.

- world-class Japan imported servo motor system can ensure the machine works smoothly and precisely.

- This is an open type fiber laser cutting machine. And this design allows the machine to process longer workpieces.

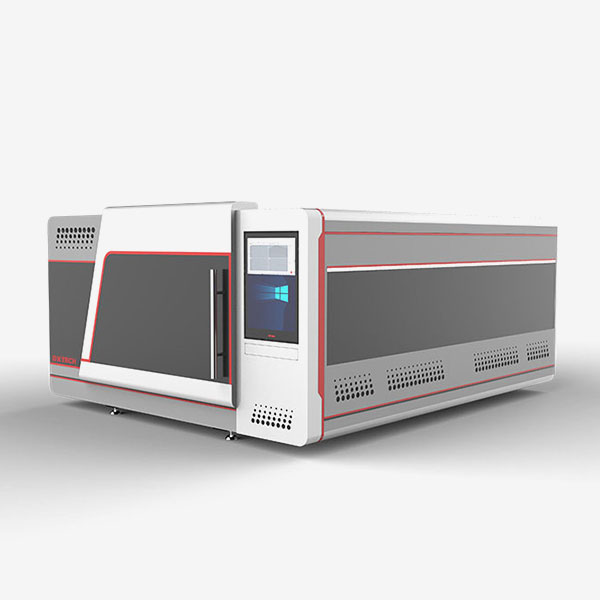

NO 4. DXTECH-1530FP: Best All Cover Fiber Laser Cutting Machine

This all cover fiber laser cutting machine adopts a fully enclosed design to reduce any laser radiation. The enclosed design can well protect the safety of users. And it is more friendly to the working environment. The working size can be customized according to customer needs. In addition, DXTECH engineers will set the most suitable laser parameters according to the metal material you need to process. This fully enclosed fiber laser cutting machine has a perfect mechanical structure, strong rigidity, and stable operation. It is suitable for various metal processing occasions, such as metal dashboards, gears, metal parts, metal signs, machinery parts and so on.

Parameters of This All Cover Fiber Laser Cutting Machine

| Model | DXTECH-1530FP |

| Machine Type | Enclosed type |

| Laser Type | Fiber laser |

| Working Area | 1500 mm * 3000 mm (can be customized per customer needs) |

| Laser Output Power | 1000W/2000W/3000W/4000w (can be customized per customer needs) |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Max Cutting Speed | 25m/min |

| Cutting Thickness | 0-20mm |

| Maximum Acceleration | 1.5G |

| Laser Source Brand | Raycus, Max |

| Working Life of Fiber Module | More than 100,000 hours |

| Control System | Cypcut |

| Servo Motor | Japan Yaskawa / Japan Fuji (optional) |

| Electrical Components | France Schneider |

| Transmission | HIWIN guide rails / PMI guide rails (optional) |

| Reducer | Japan SHIMPO |

| Cooing Mode | Water cooling |

| Certificate | ISO9001, CE, FDA, ROHS |

| Warranty | 1 year |

| Price | $59,000-$99,000 (for reference only) |

| Processing Materials | Stainless steel, mild steel, carbon steel, galvanized steel, aluminum, aluminum alloy, titanium alloy, brass, copper, iron, silicon steel, etc. |

| Applicable Industries | Metal dashboards, heat sinks, gaskets, gears and other metal parts used on automobile manufacturing, aircrafts manufacturing, household appliances, construction machinery and agricultural machinery; advertising signs, parking lot signs, street signs, metal screens, home decoration walls, metal crafts, kitchen countertops, metal furniture, public transportation frame structure, metal tools, electric cabinets, etc. |

Five Reasons to Choose This All Cover Fiber Laser Cutting Machine

- All enclosed cover design optimizes the cutting effect and protects your safety. The fully protective cover makes the laser cutting effect more smooth. And it can prevent dust and makes the working environment tidier. Also, it can protect the user from laser radiation.

- Arc-shaped anti-collision design protects the safety of users. The four corners of the machine are designed with arc-shape and it can intimately prevent accidental bumps from causing personal injury.

- High-quality laser beam produces a smooth cutting seam. This metal laser cutter is equipped with a world-class laser generator which emits excellent beam quality. The cutting lines are finer and the cutting seam is very smooth.

- Heavy-duty cast iron bed ensures stable operation. The cast iron is about 5 tons and it has strong load-bearing capacity. It can prevent the machine from deformation and greatly extends the service life of the machine.

- Aviation aluminum beam increases the cutting speed. The aviation aluminum beam is light in weight and has great toughness. It can increase the laser cutting speed a lot and makes the cutting more efficient.

NO 5. DXTECH-1530E: Best Exchange Table Fiber Laser Cutting Machine

As we all know, the speed of laser cutting is usually fast and we don’t need to worry about it. However, for batch metal processing projects, frequent loading and unloading will decrease the overall processing efficiency. To solve this problem, DXTECH manufactured this exchange table fiber laser cutting machine which makes the loading and unloading more efficient. It adopts two worktables that can exchange very quickly (just a few seconds). With the exchange platform, the machine work continuously and the processing efficiency can be greatly improved. This exchange table fiber laser cutting machine is the best choice in the manufacturing of auto parts, ships, aircraft, agricultural machinery, engineering machinery, electrical appliances, metal tools, etc. What’s more, with the high-quality machine parts adopted, this machine has long longevity and can make precise cuts on metals.

Parameters of This Exchange Table Fiber Laser Cutting Machine

| Model | DXTECH-1530E |

| Machine Type | Open type |

| Laser Type | Fiber laser |

| Working Area | 1300 mm * 900 mm to 2500 mm * 8000 mm (customized per customer needs) |

| Laser Output Power | 1000W/2000W/3000W/4000w (optional) |

| Laser Source Brand | Raycus, Max |

| Working Life of Fiber Module | More than 100,000 hours |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Max Cutting Speed | 25m/min |

| Cutting Thickness | 6 mm-35mm (depends on different laser power) |

| Maximum Acceleration | 1.5G |

| Control System | Cypcut |

| Servo Motor | Japan Yaskawa / Japan Fuji |

| Electrical Components | France Schneider |

| Transmission | HIWIN guide rails / PMI guide rails (optional) |

| Reducer | Japan SHIMPO |

| Cooling Mode | Water Cooling |

| Certificate | ISO9001, CE, FDA, ROHS |

| Warranty | 1 year |

| Price | $61,000-$100,000 (for reference only) |

| Processing Materials | Stainless steel, carbon steel, mild steel, galvanized steel, aluminum, aluminum alloy, titanium alloy, brass, copper, iron, silicon steel, etc. |

| Applicable Industries | Auto parts, electric cabinets, elevator parts, robot metal parts, rocket parts, aircraft parts, ship parts, household appliance parts, metal dashboards, heat sinks, gaskets, gears, metal screens, metal wall decoration, kitchen countertop, metal furniture, etc. |

Five Reasons to Choose This Exchange Table Fiber Laser Cutting Machine

- Exchange table increases processing efficiency. With the 10s exchange table adopted, the machine increases processing efficiency a lot in batch metal processing. The loading and unloading are more efficient.

- High stability and no deformation. The 5-ton heavy-duty cast iron bed makes the machine work stably and there is no deformation within 20 years.

- Light and rigid aviation aluminum beam. The aviation aluminum beam has light weight and good rigidity, ensuring the high cutting precision of the machine.

- High precision guide tails. This metal laser cutter adopts world-class high-precision guide rails. It shows high cutting precision and has a longer service life.

- The intelligent control system can optimize typesetting to save materials. The graphical interface and professional cutting control software can design various graphics and text. And it supports a variety of professional graphic software.

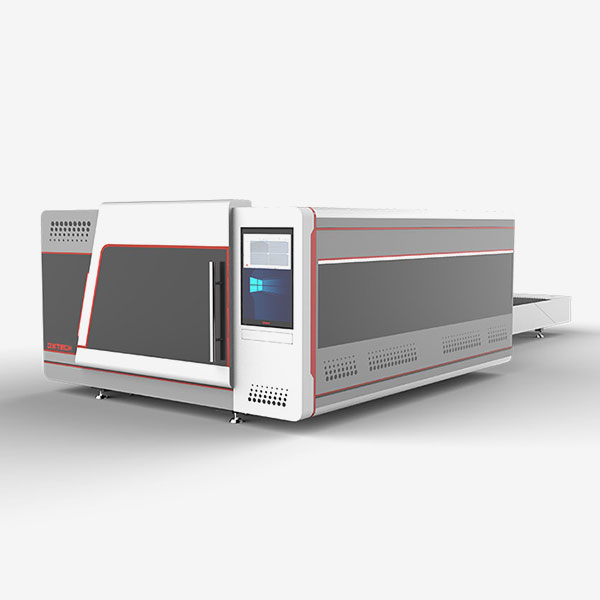

NO 6. DXTECH-1530P: Best All Cover Exchange Table Fiber Laser Cutting Machine

This all cover exchange table laser cutter integrates the laser protective cover and exchange worktable. It shows high safety and high processing efficiency in real production. This all cover exchange table laser cutter can protect the operator from personal injury. And it can prevent any dust and smoke, making the working environment cleaner. In addition, the machine is designed with the flexible 10s exchange platform, greatly improving the efficiency of loading and unloading. You can use this laser cutter to efficiently process various metal plates and the operation safety can be strongly ensured.

Parameters of This All Cover Exchange Table Fiber Laser Cutting Machine

| Model | DXTECH-1530P |

| Machine Type | Enclosed type |

| Laser Type | Fiber laser |

| Working Area | 1500 mm * 3000 mm (or customized per customer needs) |

| Laser Output Power | 1000W/2000W/3000W/4000w (can be customized per customer needs) |

| Laser Source Brand | Raycus, Max |

| Working Life of Fiber Module | More than 100,000 hours |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Max Cutting Speed | 25m/min |

| Cutting Thickness | 0-20 mm |

| Maximum Acceleration | 1.5G |

| Control System | Cypcut |

| Servo Motor | Japan Yaskawa / Japan Fuji (optional) |

| Electrical Components | France Schneider |

| Transmission | HIWIN guide rails / PMI guide rails (optional) |

| Reducer | Japan SHIMPO |

| Cooling Mode | Water cooling |

| Certificate | ISO9001, CE, FDA, ROHS |

| Warranty | 1 year |

| Price | $59,000-$100,000 (for reference only) |

| Processing Materials | Stainless steel, carbon steel, mild steel, galvanized steel, aluminum, aluminum alloy, titanium alloy, brass, copper, iron, silicon steel, etc. |

| Applicable Industries | Auto parts, electric cabinets, elevator parts, robot metal parts, rocket parts, aircraft parts, ship parts, household appliance parts, metal dashboards, heat sinks, gaskets, gears, metal screens, metal wall decoration, kitchen countertop, metal furniture, etc. |

Five Reasons to Choose This All Cover Exchange Platform Fiber Laser Cutting Machine

- The fully enclosed laser protective cover protects the operator from laser radiation. And it makes the overall machine more beautiful, more compact in structure, and more comfortable in operation. The special laser protective glass observation window makes laser processing safe and visible.

- The machine can be equipped with a dust recovery and purification system to make the processing more environmentally friendly. This will cause no pollution to the working environment.

- The two worktables can exchange very quickly (about 10 seconds). This greatly saves loading and unloading time, improves the overall processing efficiency.

- Functional control system ensures high processing precision and convenient operation. The intelligent control system can realize the precise cutting of metal products. There is no error under normal operation. And the cutting surface is very smooth. Besides, the automatic typesetting function of the control system can save materials and improve processing efficiency. The equipped graphical interface and professional cutting control software can design various graphics and text.

- World-class guide rails and high-quality servo motor ensure high processing precision. The guide rails are perfectly matched with the high-end Japan servo system to ensure high cutting accuracy and cutting quality.

NO 7. DXTECH-1530T: Best Metal Tube Fiber Laser Cutting Machine

The traditional way of metal tube cutting is to use saw blades. This couldn’t guarantee cutting accuracy and efficiency. The invention of laser cutting solved this problem. This DXTECH-1530T is specially designed for metal tube processing and it can be the best metal tube laser cutter. It has a wide range of application prospects in all walks of life. It performs the processing by clamping and rotating the metal pipe through the rotating device. This metal tube laser cutter is suitable for many occasions that need to process metal round tubes, square tubes and similar tubular materials, such as water pipes, exhaust pipes, sports equipment, auto parts, electric vehicle parts, baby carriages, furniture parts, advertising signs, etc. It has the advantages of convenient operation, quick start, low processing cost, and high efficiency. If you need a professional metal tube laser cutter, then this one can be your best choice.

Parameters of This Metal Tube Fiber Laser Cutting Machine

| Model | DXTECH-1530T |

| Machine Type | Open type |

| Laser Type | Fiber laser |

| Working Area | 1500 mm * 3000 mm (can be customized per customer needs) |

| Laser Output Power | 1000W/2000W/3000W/4000w (can be customized per customer needs) |

| Laser Source Brand | Raycus, Max |

| Working Life of Fiber Module | More than 100,000 hours |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Max Cutting Speed | 25m/min |

| Cutting Thickness | 0-20 mm |

| Maximum Acceleration | 1.5G |

| Control System | Cypcut |

| Servo Motor | Japan Yaskawa / Japan Fuji (optional) |

| Electrical Components | France Schneider |

| Transmission | HIWIN guide rails / PMI guide rails (optional) |

| Reducer | Japan SHIMPO |

| Cooling Mode | Water cooling |

| Warranty | 1 year |

| Price | $32,000-49,000 (for reference only) |

| Processing Materials | Stainless steel, mild steel, carbon steel, galvanized steel, aluminum, aluminum alloy, titanium alloy, brass, copper, iron, silicon steel, etc. |

| Applicable Industries | Automobile exhaust pipes, water pipes, oil pipes, fitness equipment, medical bed, bicycle frames, electric bicycle frames, baby carriages, kitchen storage racks, kitchenware, public transportation frames, metal furniture, metal crafts, auto parts, subway parts, ship parts, aircraft parts, etc. |

Five Reasons to Choose This Metal Tube Fiber Laser Cutting Machine

- High-quality laser generator produces high-precision cuts. The high-quality laser generator is designed with optimized optical configuration and has efficient airflow. It is stable, reliable, and has long longevity. And it releases a high-density laser beam and produces smooth cutting edges on the metal.

- Non-contact cutting ensures no deformation on the metal surfaces. The non-contact cutting has no mechanical power to the metal pipe, so there is no deformation. The processed metal products don’t need secondary processing.

- Wide processing range. The machine can perform various 3D processing effects on metal pipes, such as hole cutting, arc cutting, carving, slotting. And it can deal with various special-shaped metal tubes, such as rectangular tubes, oval tubes, square tubes, round tubes, triangular tubes, D-shaped tubes and hexagonal tubes. It is the best metal tube laser cutter in various industries.

- Strong control system ensures no limit on the processing patterns. As long as the users load the file or paint the pattern on the computer, the machine can finish the work accurately.

- This machine can be equipped with a slag removal device for the inner wall of the pipe. The device can reduce the wall hanging slag in the pipe during the cutting process.

NO 8. DXTECH-1530ET: Metal Sheet and Tube Exchange Table Fiber Laser Cutting Machine

The last top-selling fiber laser cutter that I would like to recommend is a dual-use laser cutter. This metal sheet and tube exchange table fiber laser cutting machine can be one of the most functional and efficient machines on the market. It can not only cut metal sheets with high efficiency but also specialize in metal tube processing. The exchange platform was added and greatly improves the metal processing efficiency. This fiber laser cutter can run continuously and is very suitable for batch complex metal processing projects. It has wide applications in industrial production, such as shipbuilding, auto manufacturing, engineering machinery, agricultural machinery and so on.

Parameters of This Metal Sheet and Tube Exchange Table Fiber Laser Cutting Machine

| Model | DXTECH-1530ET |

| Machine Type | Open type |

| Laser Type | Fiber laser |

| Working Area | 1500 mm * 3000 mm (can be customized per customer needs) |

| Laser Output Power | 1000W/2000W/3000W/4000w (can be customized per customer needs) |

| Laser Source Brand | Raycus, Max |

| Working Life of Fiber Module | More than 100,000 hours |

| X/Y-axis Positioning Accuracy | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.02mm |

| Max Movement Speed | 120m/min |

| Max Cutting Speed | 25m/min |

| Cutting Thickness | 0-20 mm |

| Maximum Acceleration | 1.5G |

| Control System | Cypcut |

| Servo Motor | Japan Yaskawa / Japan Fuji (optional) |

| Electrical Components | France Schneider |

| Transmission | HIWIN guide rails / PMI guide (optional) |

| Reducer | Japan SHIMPO |

| Cooling Mode | Water cooling |

| Certificate | ISO9001, CE, FDA, ROHS |

| Warranty | 1 year |

| Price | $65,000-$100,000 (for reference only) |

| Processing Materials | Stainless steel, mild steel, carbon steel, galvanized steel, aluminum, aluminum alloy, titanium alloy, brass, copper, iron, silicon steel, etc. |

| Applicable Industries | Auto parts, electric cabinets, elevator parts, robot parts, rocket parts, aircraft parts, ship parts, household appliance parts, metal tools, engineering machinery parts, agricultural machinery parts, metal decoration, metal furniture, kitchen countertop, kitchenware, fitness equipment, bicycle parts, public transportation frames, etc. |

Five Reasons to Choose This Metal Sheet and Tube Exchange Table Fiber Laser Cutting Machine

- The exchange worktable can meet the needs of a large processing volume. And the machine can work continuously. It greatly improves the productivity of metal processing enterprises.

- The integrated design of metal plate cutting and metal tube cutting makes the machine more applicable in complex processing occasions. It can process metal plates, special-shaped parts, square tubes, round tubes, metal rods and other cylindrical metal materials. This machine has wide applications in various industries.

- The mechanical design of the machine is reliable. It adopts a cast iron bed and aviation aluminum beam which have strong load-bearing capacity and high rigidity. This ensures the stable operation and long service life of the whole machine.

- The world-class servo drive and motor run stably. And they perform fast dynamic response and high positioning speed.

- The open-type design can accommodate the processing of large-size metal workpieces with a wider processing range.

Three Steps to Consider When Buying Fiber Laser Cutting Machine

After learning about the above eight top-selling fiber laser cutting machines, have you figured out what kind of laser cutter that you really need? If you haven’t got a solid plan and need some advice, then I suggest you do a comprehensive consideration through the following three steps:

Step One: Check the Warranty Period of Fiber Laser Cutting Machine

No matter what kind of machine you have, you will go through the stages of maintaining and repairing the machine after a period of use. Therefore, it is necessary to purchase a fiber laser cutter with a warranty period. The warranty can provide you with long-term quality assurance. And it can help you save a lot of maintenance costs and repair costs.

Step Two: Check the Functions of Fiber Laser Cutting Machine

To know if the machine’s function can meet your needs or not, you can look at the following three questions:

- What materials does the machine can process?

Check what kind of materials does the machine can process. And get to know what shapes the machine can cut. For example, if you need to process stainless steel plates and stainless steel pipes, then a metal sheet and tube fiber laser cutter is an ideal choice.

- How thick does the machine can cut?

The cutting thickness of the machine mainly depends on the laser power and the metal material. Check with the manufacturer how thick does the machine can cut under the given laser power. And find the most suitable laser power for your cutting needs.

- How fast does the machine can work?

Processing efficiency is critical to most metal processing projects. If possible, please perform a sample cutting to test the actual cutting speed of the machine. In addition, if you have a large enough space and need high processing efficiency, I strongly suggest you choose the machine with an exchange platform. It can help you improve the overall efficiency.

Step Three: Select the Configuration of Fiber Laser Cutting Machine

Different configurations lead to different processing performances and different prices. You need to check the following parts of the machine:

- Laser source.

Choose a reliable laser source brand that has a long working life, such as Raycus, Max, JPT and so on.

- Motor and drive.

Servo motor and drive are preferred. Although servo motor is a little more expensive than stepper motor, it has lower noise and higher precision during the operation. And servo motor and drive can make the laser cutting more stable.

- Transmission system.

Choose the guide rails from professional brands, such as HIWIN, PMI, etc. This can ensure good processing precision.

- Machine bed.

Heavy-duty cast iron bed is preferred. It can avoid deformation of the machine and ensure stable operation.

- Beam.

Aviation aluminum beam is preferred. It has light weight and high rigidity. And it can greatly improve the cutting speed of the machine.

- Control system.

Control system is the brain of the machine. Choose the control system per your specific processing needs. For most metalworking projects, it is recommended to choose a simple control panel.

Summary

This 2021 buyer’s guide introduces the eight best fiber laser cutting machines for readers. These eight fiber laser cutters are applicable to different processing occasions. And they can meet most metal processing needs for enterprises and individuals. DXTECH manufactures fiber laser cutting machines with strict standards and high-quality machine parts. So these eight fiber laser cutting machines are reliable and can help you grow your business in the near future. In addition, when you buy a fiber laser cutting machine, please remember to follow the above three steps to check the details of the machine.

Finally, if you want to customize a fiber laser cutting machine for your metal processing projects, welcome to contact us at any time. DXTECH will always uphold the goal to provide high-quality fiber laser cutting machines for customers.