With the development of cutting techniques, laser cutting has become a popular choice for most manufacturers to cut hard materials like acrylic or metal. The laser cutting technology provides an efficient, precise process, and a smooth finished edge. It reduces maximumly wastage and saves costs. Therefore, though the initial cost is more expensive than other cutting methods, laser cutting has become the common cutting technique in the cutting industry.

Laser Cutting Basics

We know laser cutting is a highly precise cutting process operated by computer software, and the metal laser cutter will create a high-energy, focused laser beam for the process. The precise process has an accurate cutting operation, which achieves the minimal wastage and maximal cost saving for cutting manufacturers.

Laser cutting has an expensive initial cost, while its cutting process is more efficient than other cutting methods. And the final result is a clean land precise pattern with a smooth, finished edge.

Choosing Stain Steel for Laser Cutting

As a kind of metal alloy, stainless steel includes at least 10.5% chromium in its molecular composition. These kinds of molecules and other elements in the stainless steel such as nickel and manganese can react with the air and water. Then a protective film was created to protect the surface of stainless steel against corrosion.

Types of Stain Steel

The properties of stainless steel, such as the resistance of corrosion, physical strength and malleability can be adjusted by altering the percentages of minerals in the metal composition. And there are four different types of stainless steel, which is commonly used as laser cutting materials.

Austenitic Stainless Steel

Austenitic stainless steel is an ideal material for stain steellaser cutting service. It is the commonest stainless steel used in the construction industry. This kind of stainless steel has a structure that is very similar to common steel. And the hardening process of the steel happens without heating, it is metal material with very high strength.

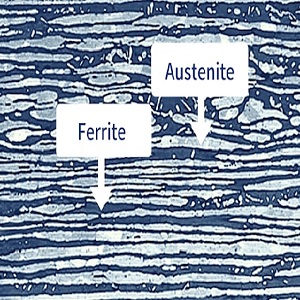

Austenite is the primary crystalline structure of austenitic stainless steel.

Nickel, manganese, and nitrogen are added as the austenite stabilizing elements into the crystalline structure.

The crystalline structures ensure the austenitic steels from heating harden and make them non-magnetic.

Ferritic Stainless Steel

Ferritic stainless steel includes different elements, such as chromium and carbon. As one of the stainless steel, ferritic stainless steel also contains at least 10.5% chromium.

It is very ideal for stainless steel cutting because of its thinner sections with smaller even no welds, and it has resistant to stress corrosion cracking.

Martensitic Stainless Steel

Martensitic stainless steel is made of chromium and carbon, and also a material that can be tempered and hardened. This type of stainless steel can be hardened by heat treatment, such as quenching and stress relieving, or by quenching and tempering (QT).

Nowadays, manufacturers consider it as a magnetic type of steel with less formability and commonly use them as requiring sheet and plated metals. It is commonly applied medical tools, especially used as scalpels and razors.

Duplex Stainless Steel

Ferritic and austenitic metals combine the duplex stainless steel, and this type of stainless steel has a higher strength feature than either of ferritic and austenitic metals by itself. Duplex stainless steel has resistance to stress, corrosion, and cracking, and is also magnetic and well-performed in welding. It behaves well when used in the stainless steel cutting process.

Duplex stainless steel includes a higher chromium content, which reaches 20-28% and provides better corrosion resistance, especially chloride stress corrosion and chloride pitting corrosion. Therefore, it is commonly applied as the form of pipelines and pressuring in the offshore oil and gas industry,

How to Make Stainless Steel Laser Cutting

As an efficient working process and convenient operation, using CNC stainless steel cutting machine has become a popular stainless steel laser cutting method for manufacturers. Before creating a stainless steel business, you should know some stainless steel laser cutting basics.

6 Process of Laser Curtting Stainless Steel

Before the stainless steel laser cutting service, you should learn how to operate a metal laser cutter. There have 6 processes of stainless steel laser cutting that include the total cutting steps from the beginning to the end.

- Cutting pattern design: manufacturers should design a reasonable pattern according to the final product because the cost of after-laser change is very expensive and troublesome.

- Put the pattern into the computer: people control the CNC stainless steel cutting machine by computers. With computer software, metal laser cutters can also finished complex pattern cutting.

- Laser route generation: the operate computer creates a laser route for cutting.

- Laser creating: metal laser cutters create high-energy and focused laser beam for cutting.

- Cutting precisely: stainless steel cutting is a precise process and finally creates a clean line for the cutting patterns.

- Metal cutting finished.

Considerations of Laser Cutting Stainless Steel

Part design:

As the basis of the CNC stainless steel cutting cutting process, design a reasonable part has become the most important step in the stainless steel cutting cutting process.

The part you design for the laser cutting should according to the final products to ensure efficient cutting work, because the changing cost of after-laser is expensive.

On the other hand, if the simpler part design is, the higher working efficiency your laser cutting will be.

Materials:

Stainless steel cutting manufacturers consider whether the metal material has a good performance during the laser cutting process.

The laser beam is high temperature and energy and can melt stainless in a millisecond. If the material has no heating resistance, it is a very possible to break during application.

Application

Nowadays, stainless steel is very popular in some special industries, such as nuclear power, marine, and architecture industries. Therefore, stainless steel laser cutting service is ideal for these industries.

Architect Industry:

You may see may fashion, smooth, elegant outlook buildings with stainless steel in flourishing cities like New York, Paris, London, and Beijing. This kind of special stainless steel is also called Architecturally Exposed Structural Steel (AESS). It is replacing concrete in some high-end building design. AESS is well known for its corrosion resistance, refined surface finishes, strength, hygienic qualities, and all of the factors are the reasons why so many architects and engineers are enamored with this material.

Marine industry:

Stainless steel is a very suitable material for the manufacturing of lift and boarding equipment for large or small sea crafts because of its corrosion resistance. Duplex stainless steel provides a better corrosion resistance than other stainless materials, so most of the marine manufacturers use this type of stainless to build construction of nautical cranes against the corrosion from saltwater, humidity, and temperature.

Stainless Steel Laser Cutting Machine

Most of metal laser cutters can achieve the metal cutting, while not all of them suite for stainless steel cutting. Fiber metal laser cutter and laser metal cutting machine are the commonest cutting machine for stainless steel laser cutting.

Laser metal cutting machine: This type of cutting machine can deal with nearly all kinds of metal materials, such as stainless steel, mild steel, aluminum, brass, etc. This kind of machine can create different types metal laser cutting, such as stainless steel laser cutting, etc. So there may have some different results when it cuts different metal materials.

Fiber metal laser cutter: Fiber laser cutting process is more efficient and precise than other cutting methods, and the long lifetimes is attractive to most manufacturers.

Fiber Laser Cutting Machine

With the fiber laser technology, the fiber metal laser cutter provides metal precise cutting. The fiber laser beam achieves quicker cutting speeds and high-quality cutting.

This kind of laser has short beam wavelength, usually, 1,064nm, which is 10 times shorter than Co2 laser and becomes the ideal laser cutting method of stainless steel.

Features of Fiber Laser Cutting Machine

- The fiber metal laser cutter is available for double balls to screw closed-loop system and open-type CNC system, which ensure high working efficiency and accurate cutting during the quicker laser cutting.

- Metal laser cutters are optional at fiber laser 500W, 1000W, 2000W,3000W, which is equipped with the fiber metal laser cutter. Choose the right fiber laser machine will help you achieve the maximization of long-term return on investment and revenue.

- Conforming with the CE standard ensures the safe during the fiber laser cutting process.

Laser Metal Cutting Machine

This type of laser cutter nearly can cut all kinds of metal materials, and create cutting process, such as stainless steel laser cutting. It is a kind of CNC metal laser cutter for sheet metals, metal plates, metal profiles, metal tubes, and metal pipes. Therefore, it can be called as CNC stainless steel cutting machine. It is versatile and preferred by cutting manufacturers.

Features of laser metal cutting machine

- Most laser metal cutting machines equipped with more than 500w laser, and it is a very high intensive laser beam with a single wavelength.

- Laser metal cutting machine proves non-contact processing for metal materials without cutting force, deformation, and tool wear. And laser metal cutting machine will have a precise, efficient cutting with accurate distance.

- This type of metal laser cutter is automatic and very easy to operate.

Stainless Steel Laser Cutting Machine Manufacturer

If you want to create a stainless steel laser cutting business or stainless manufacturing, invest in a stainless steel metal laser cutter is very necessary. A high-quality cutting machine will provide efficient work for you. While choosing the right cutting machine manufacturer can save lots of time and cost for you at the machine selection.

3 Considerations of Laser Cutting Manufacturers Selection

- Your partner should have a great deal of experience. Excellent laser cutting manufacturers should have rich experience of laser cutting and prepare to solve any problems their customers may meet during the stage of using the machine.

- Work closely with their customers. Stainless steel metal laser cutter manufacturers should still work closely with their customers to answer questions about products, equipment delivery, solving problems, and machine maintenance.

- Choose the manufacturer who has its own research & development basement. The laser cutting machine companies which have their own R&D basement usually have advanced laser cutting technology, and very sophisticated in the laser cutting industry.

Stainless Steel Laser Cutting Machine in China

With the development of laser cutting technology, the world laser cutting market has changed. Nowadays, the Chinese laser cutting market has developed and occupied a large market value in the world. Chinese stainless steel laser cutting machine manufacturers provide high-quality cutting machines and stainless steel laser cutting service. Nowadays, it has become more and more reliable to cooperate.

3 Advantages of Chinese Manufacturers

- The stainless steel laser cutting machine in China has high quality and affordable price. China has high productivity, and the labor cost is relevantly lower than developed countries like the USA or the United States. Therefore, the Chinese machine will have a lower price than the equivalent from the Euro countries.

- Trade policy from China government to support import.

- Integrated service system and sincere attitude. The environment of intensive market competition creates a relevantly comprehensive service system. Chinese laser cutting manufacturers provide buying instruction when their customers want to invest in the metal laser cutter. They also still having after-service, keeping a close working relationship with them. Convenient machine delivery, long-time machine maintenance has become the reason why more and more buyers prefer Chinese machines and Chinese stainless steel laser cutting service.

Connect with Dxtech

Dextech provides excellent stainless steel laser cutting machines and high-quality stainless steel laser cutting services for their customers. We have a fiber metal laser cutter and laser metal cutting machine for you to deal with stainless steel and other alloy cutting.

We are still working closely with our customers, and prepare to solve any problems which confuse you at any time. If you have any questions about stainless steel laser cutting, connect with us, leave your comment or e-mail us, we are very pleased to solve problems for you.