Laser Welding Machine

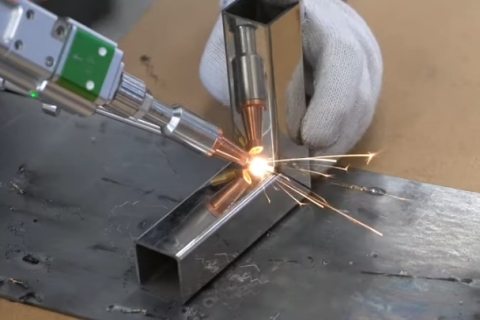

Laser welding machine applies the way of non-contact welding, which is a new type of welding method. In the processing process, high-energy laser pulses find application in locally heating the material in a small area. The energy of the laser radiation diffuses into the material through thermal conduction. And then the melted material will form a specific molten pool.

show more

Laser welding is mainly applicable to the welding of thin-walled materials and precision parts. It can realize the spot welding, butt welding, stack welding, sealing welding, and other welding processes.

show less

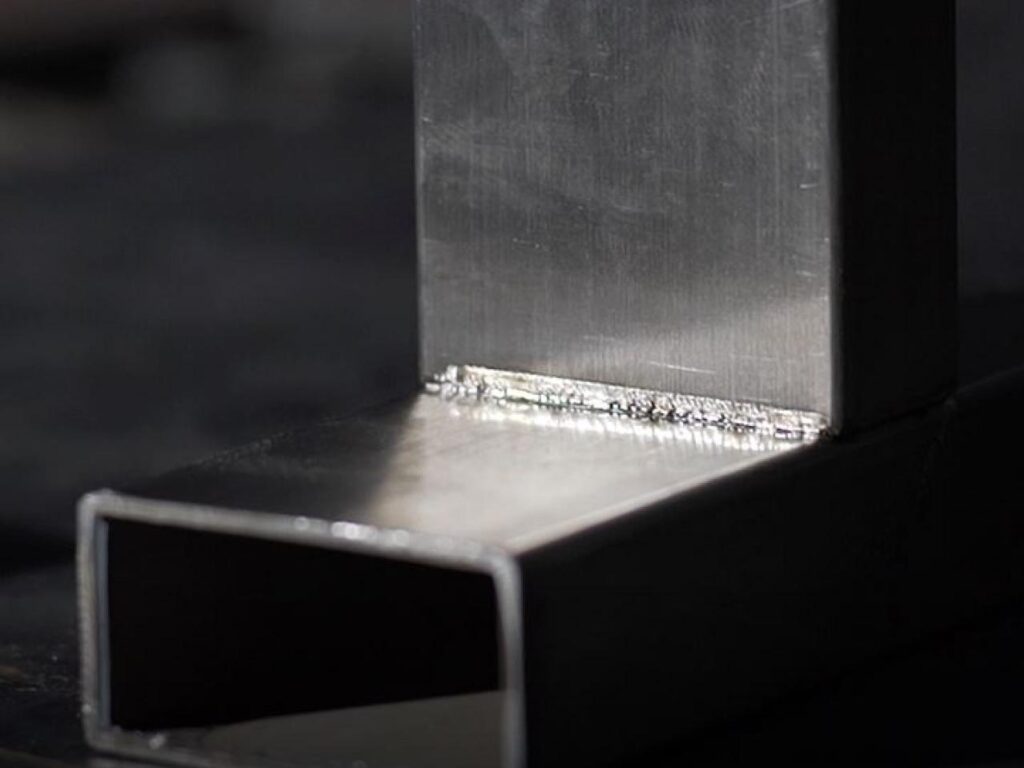

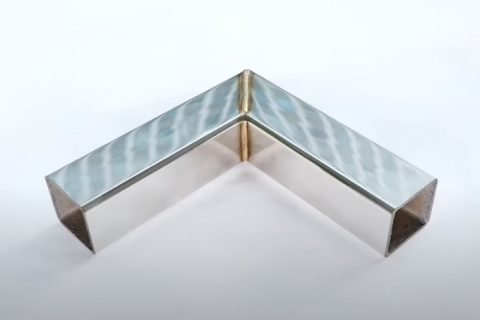

Laser Welding Machine Samples

The hand-held fiber laser welding machine is used for welding various metal materials, and can weld stainless steel mirror characters, stainless steel electroplated characters, precision stainless steel characters, iron paint characters, etc. Used in lighting, mold and other industries, communication equipment, medical treatment, electronics, copper parts and small welding processing industries.

We provide free proofing, welcome to consult.

Specifications

| Brand | DXTECH | ||

|---|---|---|---|

| Application | LASER WELDING | ||

| Applicable Material | Metal | ||

| Laser Type | Fiber Laser Source | ||

| Welding speed | 0-120mm/s | ||

| Fiber Length | Standard 10m; Maximum 15m | ||

| Pulse Width | ≤20ms | ||

| Focal Spot Diameter: | 0.1-3.0mm | ||

| Laser Power | 450W,1000W,1500W, 2000W, 3000W | ||

| Laser wave length | 1080nm | ||

| Welding gap | ≤1/5 of the thickness of sheet metal | ||

| Consumable | Nitrogen welding, output pressure 0.2Mpa | ||

| Core Components | Pressure vessel, Motor, Bearing, Gear, PLC, Pump, Engine and Gearbox | ||

| Working Voltage | 380V/50HZ or 220V optional | ||

| Operating Temperature | 5-45℃ | ||

| Operating Humidity | ≤70%, No condensation | ||

| Cooling Mode | Water cooling | ||

There is an increasing demand for laser welding machines in the market. And many manufacturers are inquiring about and eager to buy this machine. However, the buyers shall not only consider the price. It needs to purchase a corresponding laser welding machine according to processing needs. For example, there are many performance parameters that affect the quality of the laser welding machine. Therefore, how should users purchase the laser welding machine? And what aspects should they pay attention to? Below DXTECH shares some points for purchasing laser welding machines.

1. Materials for laser welding

At first, the buyers consider using which material for laser welding. Some buyers may look for the jewelry laser welder, and some inquire about the laser welding aluminum machine. The buyers can find out what machine that the peers in the same industry are using. Of course, they can ask the suppliers or professional engineers for suggestions.

2. The energy of the laser pulse

The energy of a laser pulse refers to the maximum output energy of a single laser pulse. With a certain laser power, the higher the energy of the laser pulse, the lower the emission frequency. The energy of the laser pulse is a main parameter of the laser. Because it determines the maximum energy that the laser can produce.

3. The strength and scale of the factory

Usually, the laser welder produced by small-size manufacturers is not very good. Because small manufacturers need to control costs, they have relatively little manufacturing investment. They often use low-cost parts and low-quality design, which makes the laser difficult to focus accurately. The diameter of the laser spot of their laser welding machine cannot reach to the standard at all. Therefore, it is recommended to purchase the laser welding machine produced by DXTECH. The quality, safety, and service of the laser welders for sale can get more guaranteed.

It is important to maintain the laser welding machine regularly. The following offers some suggestions for the maintenance.

1. Check the conductivity of the internal circulating water

The purity of the cooling water laser cooling technology is the key to ensure the laser output efficiency. And it will affect the service life of the laser components. The operators shall check the conductivity of the internal circulating water weekly. The internal circulating water must be replaced once a month.

2. Check and adjust the laser cavity

The operators can often use the black paper to check the laser output spot. If finding any laser spot unevenness, the operators shall adjust the laser resonant cavity in time. This is to ensure the beam quality of the laser output. The commissioning operator must have a common sense of laser safety protection. And they must wear special laser protective glasses while operating the laser machine. The adjustment of the laser must be carried out by specially trained personnel. Otherwise, it will damage the parts on the optical path due to laser misalignment or deviation adjustment.

3. Check the optical path components of the laser welding machine

The operators shall regularly check the components in the optical path to ensure the laser in a normal working state. Especially after the continuous operation or a long time without operation, please check the optical path before starting. The operators need to make sure the parts, such as dielectric film and lens glass are not contaminated. If there is contamination, the operators shall clean up in time. Therefore, the optical components will not be damaged under strong laser irradiation.

The above is the information about the maintenance methods and requirements of the laser welding machine. Hope it will be helpful for you.

The operators need to operate the laser welding machine by strictly following the operating instructions. The following briefly introduces the operation steps of the laser welding machine for reference.

1. Preparation before start-up

- The operators shall be competent and wear the protection articles according to regulations.

- Keep the workplace dry and adequate illumination, and there are no obstacles in the working area.

- There are no flammable or explosive materials around the laser welding machine.

- Machine inspection before the start-up

- Appearance: The appearance of the laser and the water cooling machine shall be clean. There is no oil dirt or the materials unrelated to the welding processing. And the auxiliary tools shall be intact and clean.

- Cooling system: The cooling water and the water in the laser shall be between the minimum and maximum levels. There is no leakage at the joints of the cooling water pipeline. The cooling water shall be the deionized water or the distilled water, and be kept clean. Sometimes, the environment temperature becomes below 0℃ or the machine will be shut-down for a long time. In this case,it needs to drain off the cooling water.

Before start-up, the operators shall check the machine firstly. After confirming there is no problem, the operators can start up the machine.

2. Procedures of start-up

- Turn on the main power supply.

- Turn on the air switch ofthe laser power supply.

- Check the cooling fan of the laser to ensure its normal operation.

- Turn the switch on the control panel of the laser machine to the position “On”.

- Press down the green button “START” to start the machine. At this moment, the operation screen will display the initialization process. The progress bar will show the progress of starting the system.

- Click the control menu on the operation screen of the laser welding machine.

- Turn on the switch “Laser” on the control panel of the laser.

- Turn the switch “Power” on the working table to the position “On”.

3. Operation steps

- According to the thickness of the welded pipe, choose the appropriate welding procedure correctly.

2) Adjust the position ofthe light spot to make its center located on the welding

3) Choose the welding program and adjust parameters if necessary.

4) Click the button for automatic welding on the panel to start automatic welding.

5) Make the operation record of laser welding.

Notes:

- Do not touch the welding part when its temperature doesn’t reduce to room temperature after the This is to prevent high-temperature scalding.

2. The operators shall not observe the welding condition closely during the weldingprocess. Otherwise, they may be injured by spattering welding slag.

4. Procedures for turning off

1) Turn off the power switch on the control panel on the working table.

2) Turn off the laser switch on the laser control panel.

3) Click "shut down" on the control menu of the main menu of the operation screen. And the system will automatically complete the shutdown.

4) Switch off the power key on the laser control panel.

5) Turn off the laser power switch.

6) Disconnect the power air switch.

Working principle:

The working principle of the laser welding machine is to use the pulse laser produced by laser for welding. After beam expanding, reflection and focusing, the laser beam radiates on the surface of the work-piece. The surface heat diffuses to the internal through heat transfer. And the work-piece begins melting to form a specific molten pool. In this way, the laser welding machine completes the precision welding. This is the processing that can not be realized by traditional welding technology.

· Working features:

In comparison with other welding technologies, the laser welding process has the following features.

1. High efficiency

Fast welding speed, large depth, and small deformation.

2. Non-contact processing

No need to clamp the work-piece and do the surface treatment. The laser welding machine can weld the parts hard to access, and implement non-contact welding. Therefore, it has great flexibility.

3. Welding refractory materials

It can weld refractory materials such as titanium and quartz. And the laser welding machine can weld dissimilar materials with good effect.

4. Micro welding is possible

As the laser beam can form a small spot after being focused, the laser welder achieves accurate positioning. Therefore, it can be used for the assembly welding of micro and small work-pieces in automatic mass production.

5. Welding at room temperature or under special conditions

The laser welding machine can weld at room temperature or under special conditions, and the operation is simple. When the laser passes through an electromagnetic field, the beam will not deviate. The laser can weld materials in the vacuum, air, and certain gas environments.

6. High power density

After the laser is focused, the laser power density is high.

The laser welding machine adopts the split-type design and modular structure. Thus, it is suitable for applying into various industries. The machine has an LCD screen display and a centralized button operation. Therefore, the operation becomes more convenient. It can also be combined with the assembly line production and has strong applicability.

Laser welding machine, often called laser welder, is one of the important machines for the application of laser technology. The laser welding process is thermally conductive, that is, laser radiation heats the surface of the work-piece. The laser welding machine uses high-energy laser pulses to locally heat the materials in a small area. The energy of the laser radiation diffuses into the material through heat conduction.

The computer controls the movement and parameters of the laser, such as width, peak power, and repetition frequency. And the laser melts the work-piece to form a specific molten pool to reach the purpose of welding. The laser beam welding has the unique advantages of smooth welding seam, small focus spot, and high positioning accuracy. Therefore, the laser welder has been successfully applied for the precision welding of micro and small parts.

· Categories and Applications of the laser welder:

Categories:

According to the working methods, the laser welder can be mainly divided into the following three types.

Handheld laser welder

Also known as the manual welding machine, or portable laser welding machine, it can be mainly used in the molding manufacturing industries. For example, it is applicable to the molding industries of mobile phones, digital products, automobiles, and motorcycles. And people also mostly use it as the handheld laser welder for manual welding. This laser welder easily welds metal materials, such as stainless steel, iron and galvanized sheets.

Automatic laser welding machine

This machine is suitable for automatic welding of metal work-pieces in straight lines and circles. It is commonly used in phone batteries, jewelry, electronic components, sensors, clocks, precision machinery, communications, and handicraft industries.

Fiber laser welding machine

The fiber laser welder has a good laser beam welding quality and high welding accuracy. It is suitable for welding microelectronic components, precision parts, high-end digital components, optical fiber connectors, and medical equipment.

With stronger energy and greater heat, it instantly reaches the welding point and melts the materials. People often use it in the medical, mobile phone, electronics, hardware, instrumentation, optical communication, and aluminum industries.

Applicable materials:

This machine is suitable for welding the same materials, such as stainless steel, gold, silver, and alloy. And it is also applicable for welding many kinds of dissimilars metal materials. For example, the laser welder can weld copper and nickel, nickel and titanium, low-carbon steel and copper.

Nowadays, most manufacturers provide laser welding services for their customers which can be used for various materials like aluminum, titanium, etc. There are different features of each type of material.

- Laser welding aluminum: Laser welding is the most popular technology for aluminum welding. Laser welding aluminum is the ideal of quick and clear aluminum welding service, and create deep weld penetration.

- Laser welding titanium: With clear and efficient welding, advanced laser welding titanium technology can create a reasonable cost for their customers.

- Laser welding stainless steel: Laser welding machine for stainless steel has become the best choice for manufacturers to weld stainless steel. The laser welding machine for stainless steel can create a perfect welding result and deep weld penetration.

- Laser welding jewelry: Manufacturers weld jewelry with jewelry laser welding machine. The precise welding technology helps manufacturers deal with delicate jewelry design.

Applicable industries:

The laser welder is applicable to the electronic components, precision machinery, communications, and other industries. There are also many users in the phone batteries, sensors, medical devices, craft gifts, and clocks industries.

Laser. The laser is the core of laser equipment. The higher the laser power, the higher the requirements for the laser rod and cooling system. Therefore, the price of the overall laser welding machine is higher.

Control system. Under the premise that other functions are the same, the price of an automatic laser welding machine is higher than that of a manual laser welding machine. Because the automatic laser welding machine needs a control system, a CCD camera monitoring system, and other supporting automation settings.

After-sales service of laser welding machine for sale not only includes the professional degree of the business in the installation, operation, and maintenance of the laser welding machine. And we all know that the laser tube and reflective lens of the laser welding machine are consumables. And they all have a certain life span and need to be replaced after a period of use. This requires the manufacturer to provide a strong after-sales service guarantee to provide these consumables in a timely manner. Therefore, the price of laser welder with more complete after-sales service is relatively high.

The user's processing requirements include processing materials, processing effects, etc. The processed material generally refers to the attribute of the processed material and the thickness of the material. The processing effect usually refers to the level of processing quality requirements. Therefore, the stricter the user's processing requirements, that is, the higher the machine configuration requirements, the higher the price of the corresponding laser welding machine. In addition, for laser welding machines that must be customized, it may be accompanied by improvements in machine technology, so the price is higher than ordinary machines.

The laser welder cost is combined with the quality and the laser welding systems the machine has. Usually, the laser welder for sale has its own laser welding systems, the advanced laser welding systems need high laser welder cost, the laser welding machine price is also high. Different types of laser welder have different prices. The fiber laser welding machine price is different from the CO2 laser welding machine price. And the handheld laser welding machine price is different from others.

In addition to the core components mentioned above, processing requirements and after-sales service factors have a great impact on the price of laser welding machines. The machine brand, processing function, assembly process, etc. also have a great influence on the laser welding machine price.

<td$5,000.00-$11,000.00

|

Type of laser welder

|

Price Range |

|

Basic hand-held laser welder

|

$9,580.00-$25,880.00 |

|

Advanced hand-held laser welder

|

$18,800.00-$25,800.00 |

|

Basic automatic laser welder

|

$4,500.00-$5,500.00 |

|

Advanced automatic laser welder |

DXTECH Quality Assurance

2 years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.