Laser cutting has been around for decades and today still helps manufacturers cut materials of all kinds. A laser cutting machine uses a focused beam of light in a specific area and provides a cut as you move the laser beam across the material you’re working with.

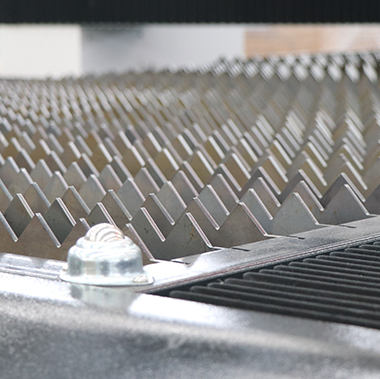

A cutting machine is made up of the cutting head and table. A laser cutting table is the working area that the laser or plasma can cut on in your laser cutting machine. The laser cutter was first invented by Kumar Patel in 1961 and over the last few decades has been refined to a highly accurate, automated tool.

Laser Cutting Use Cases

A laser cutting table can benefit many industries from automotive to medical, to small businesses. It’s one of the most common manufacturing processes used throughout the world in all industries. For example, it’s used in the engineering, electronics, automotive and aerospace industries. In the medical field, it’s commonly used to make life-saving medical devices that require a high level of precision and detail.

Reasons to Purchase a Laser Cutting Table

It’s a great tool because you can ensure quality production at speed. It may require an upfront cost, but in the long run, the investment is worth it. Here are a few reasons why you may want to invest in a laser cutting table.

Product Design and Speed

Laser machines can reduce production costs as they make cuts and etches in a simple step without the need for manually sawing and drilling into the material. These machines are much faster than traditional cutting methods, even for more complex cuts.

Precision and Repeatability

Laser cutting machines have a high standard of accuracy. Make precise cuts of +/-0.1 mm of accuracy. And, you can program the machine to repeat cuts with high accuracy, so parts are almost exact replicas.

Automation

Laser cutting machines are typically automated, so you can create designs and make cuts with just the touch of a button. Control the design easily on software and then upload your design to the computer numerical controlled (CNC) machine. The machines are intelligent enough to gather analysis and results and if there are any abnormalities, and an alarm will show.

Long-lasting

A laser cutting table can last on average about 8000 hours of working, under proper conditions and maintenance. That’s over four years of full-time use, and it can last even longer depending on how much you use it.

Types of Laser Cutting Tables

When choosing a laser cutting machine, keep in mind that there are two types of cutting tables, a laser cutting table and a plasma cutting table. Also, remember that the size of your cutting table will dictate what you can use it for.

Benefits of a Laser Cutting Table

A laser cutting table can cut materials of all types using a high-powered C02 laser with high accuracy.

Precision Cuts

A laser cutting table provides precise cuts giving you very accurate results.

The precision of a laser cutting table can also be used for detail work like engraving and decorative fine detail on the surface of the workpiece, or rastering.

Flexibility

A laser cutting table is flexible enough to use for a variety of materials including metals, some fabrics, paper, plastics, and even wood.

DXTECH, a professional laser manufacturer based in China, offers a variety of laser cutting tables for sale, and provides advanced fiber laser cutting machine.

Benefits of a Plasma Cutting Table

A plasma cutting table and a laser cutting table both are extremely powerful but have slightly different use cases. Like laser cutting, plasma cutting has been around for decades, and today the technology is more refined.

Thick Cuts

A plasma cutting table uses a high-power plasma beam to melt metal and cut through it. Millions of companies use an industrial plasma cutting table because they offer a low operating cost and can cut through extremely thick materials like stainless steel and aluminum.

Plasma Cutting Table vs Laser Cutting Table

A plasma cutting table takes less energy than a laser cutting table, which means you have lower operating costs with a plasma cutting table. And, plasma cutting tables easily cut through several inches of material, unlike laser cutting tables. However, they are not as precise as a laser cutting table and cannot cut the same variety of materials. Plasma cutting tables can only cut conductive metals.

Note that laser cutting machines are powerful tools that can be dangerous. The thermal cutting method melts materials, which can emit gases and dangerous fumes (especially when cutting plastic). You will need a good ventilation system and some basic training to ensure a safe working environment.

Laser Cutting is Quick and Easy

Laser cutters are a type of computer numerical controlled (CNC) machine, which means a designer can build a design into a software and send it to the laser cutter to cut out the design automatically. So, designs can get cut in just a few minutes without any manual cutting. A CNC laser table is an industrial cutting table and is economical for many companies, including SMBs.

Cutting Table Size

A laser cutting table size determines the size of the material you can work with. With a bigger cutting table, you can cut larger pieces or multiple pieces at once than you can with a small cutting table. Also note that cutting tables have minimum dimensions for the smallest size your design can go.

DXTECH offers several laser cutting tables sizes including:

- 4X8 CNC plasma table

- 4×4 CNC plasma table

- 5×10 plasma table

Things to Consider Before Buying a Laser Cutting Machine

Do your research before selecting a laser cutting machine to ensure you get the right model for your needs. Questions to ask yourself before buying a laser cutting table include:

- What type of work do you want to perform? Engravings, cuts, etc

- What materials will you work with?

- What size do you need to work with?

- How thick is the material you want to work with?

- How quickly do you need to create materials?

- What is your budget?

Contact us if you have any questions or would like to learn more about cutting tables for sale at DXTECH.