Do you know if glass can be cut with a laser? Glass is a non-metallic material that is commonly used in all walks of life. For glass fabricators, glass products with both beauty and practicality have huge market potential.

The traditional methods for glass cutting easily cause horizontal cracks, and the products need further heat treatment to strengthen the cutting edge. This will lower the cutting efficiency and increase the processing costs.

With the development of science and technology, laser cutting is showing outstanding performance in processing a variety of non-metal and metal materials. In this article, we will analyze how laser cut glass technology brings new opportunities to glass products. If you are engaged in glass processing, then you must not miss this laser cut glass guide.

Introduction of Glass

Glass is a kind of inorganic mixture made of various inorganic minerals. It has good light transmission and sound insulation properties, as well as high chemical stability. Glass can be made into various daily necessities and indoor decorations, such as glass cups, glass vases, glass bottles, glass bulbs, glass decorative walls, etc.

There are many categories of glass materials. According to the color of the glass, there are colorless glass and stained glass. According to the composition, there are silicate glass, borate glass, phosphate glass and so on.

Glass materials have a wide range of applications. And glass products have great market potential in various industries. Therefore, how to process glass with high efficiency and high precision is an important issue for glass manufacturers to think about.

Glass is brittle, so it is more difficult to process than other non-metal materials such as wood and acrylic. The traditional method of cutting glass is to use diamond blades, saws, etc. to mechanically cut the glass. And people need to trim and polish the cutting edges, which costs a lot of time and energy. Besides, mechanical cutting is easy to produce tiny cracks on the cutting edge, and a further heat treatment is required to strengthen the cutting edge.

Applying laser technology to glass cutting is a long-term development path for the glass processing industry. What’s more, the laser engraving technology is capable of engraving complex patterns with high precision, which brought unprecedented development opportunities for glass manufacturers. Therefore, laser cutting glass is one of the best ways for glass manufacturers and processing companies for self-transformation and upgrading.

Laser Cut Glass: Is It Feasible?

When it comes to laser cut glass, many people think that it is not feasible. The principle of laser cutting is based on materials that can absorb the wavelength of laser light and melt. Glass is transparent, so most of the invisible light can penetrate the glass without being absorbed. But glass absorbs laser light far better than metal. Glass has a higher absorptivity when the laser wavelength is greater than 5um. The wavelength of the CO2 laser is 10.6um, which is very suitable for cutting glass.

Laser cut glass has a long history of development. As early as the 1970s, some companies tried to use kilowatt-power CO2 lasers to process glass. However, due to the high laser power, the local thermal effect of the glass was too large, and it was difficult to ensure the cutting slit neat and smooth, and the glass needs further polishing. Glass is a poor thermal conductor and requires low laser power. Using a low-power CO2 laser cutting machine can separate the glass while controlling the thermal influence within a certain range. Thanks to the CO2 laser cutting technology, laser cutting glass can be widely used in various industries.

Laser Cut Glass & Laser Engrave Glass

According to the different processing effect, we can divide laser cut glass into two types: laser cut glass (to separate the glass) and laser engrave glass (carving on the surface of the glass).

Laser Cut Glass

Laser cut glass mainly uses a CO2 laser cutting machine. This is because the CO2 laser cutting machine has high light absorption characteristics. It uses the heat melting effect of the laser beam to process the glass. The laser cutting head can emit a laser beam with high energy density, which melts the glass part and then performs rapid cooling so that a vertical stress zone (100 microns to several millimeters) is generated inside the glass, and a chipless and transverse crack appears in this direction. At the same time, the edge strength can be guaranteed.

The CO2 laser cutting machine can easily cut thin glass, such as glass capillaries. For thick glass cutting, the CO2 laser engraves linear scratches on the surface of the glass, and then we can manually snap along the tangent line or snap off with pliers to separate the glass along the laser line.

The process of laser cutting glass relies on thermal mechanical stress, and the fracture depth and slitting speed are closely related to the expansion coefficient of the glass material. Most ordinary glass can meet the minimum requirement of the expansion coefficient.

Laser Engrave Glass

Laser engrave glass is another important application of laser technology on glass materials. It only engraves on the glass surface without destroying the deep structure of the glass. The laser can engrave 0.02-0.125 inches of glass materials. You can watch this video to learn how a CO2 laser engraving machine engraves the glass plate. As you can see in the video, laser engrave glass shows high efficiency and good precision. What’s more, laser engrave glass does not produce any cracks on the glass.

Advantages of Laser Cut Glass

Compared with the traditional mechanical glass cutting methods, laser cut glass has the following advantages:

- Laser cut glass is non-contact cutting. It does not cause any cracks on the glass surface and no debris on the cutting edge, which greatly improves the qualification rate of glass products. Moreover, there is no tool wear during the laser cutting glass process, which saves a lot of maintenance costs for users.

- Laser cut glass has high precision. The cutting process is fully automated, which avoids any errors caused by manual intervention. Also, the laser beam focuses on a very small light spot and automatically moves according to the preset path of the control system. For the enterprises who need to mass-produce glass products, laser cut glass can help them improve product quality a lot.

- The cutting slit of laser cut glass is narrow. And there is little to no deformation on the glass product. Appropriate laser cutting parameters can control the thermal affected zone to be very small.

- Laser cut glass has a high degree of automation with high adaptability and flexibility. It has unlimited profiling cutting capabilities, easy to realize automatic cutting. And it can be applied to a variety of glass materials.

- Laser engrave glass can deal with complex patterns, and does not break the deep structure of the glass. This makes the artistic value and commodity value of glass products have been qualitatively improved in all walks of life.

Laser Cut Glass Applications

Laser cutting technology has outstanding performance in glass fabricating. So it has been widely used in various glass-related fields. In the following section, we listed some creative ideas of laser cut glass and laser engrave glass.

Laser Cut Stained Glass Decorations

Stained glass has beautiful colors and is an ideal material to make various exquisite decorations. If you want to make decorations with stained glass, then a glass laser cutting machine can help you finish this work.

The glass laser cutting machine can help users cut various shapes of stained glass more easily. Moreover, the cutting seam is smooth and there is almost no need for further grinding. You can directly assemble the pieces to make the decoration that you want to make. Laser cut stained glass decorations can decorate indoor walls and tables, and the matching of different colors can meet the tastes of different people.

Laser Cut Stained Glass Lampshades

Similar to laser cut stained glass decorations, the laser cutting machine can also make beautiful stained glass lampshades. Prepare a variety of colors of glass as the raw material, and cut them into specific shapes with the laser cutting machine. Then, inlay the glass pieces on the lampshade frame. You can get a retro-style colored glass lampshade. The laser cut stained glass lamps can bring an artistic atmosphere to the place. It can decorate your private space, such as bedroom, living room, etc. In some public places such as cafes, bars, art galleries, museums, etc., this kind of laser cut stained glass lamp is also very popular among customers and visitors.

Laser Engrave Glass Cups

It can be said that glass cups are the most commonly used glass products in our daily life. There is no decorative pattern on the ordinary glass, which is inevitably a bit monotonous. But the birth of laser engraving technology makes glass engraving possible.

The laser engraving machine can engrave various patterns or characters on the glass surface and make the glass cups more beautiful and unique. This is a big opportunity for glass manufacturers. They can use the laser engraving machine to engrave various types of patterns to meet the tastes of different customer niches. Moreover, it is a great idea to customize glass cups according to customer preferences.

Laser Engrave Glass Wine Bottles

Laser engraving technology has great potential in wine bottle production. The laser can engrave beautiful patterns on wine bottles. The wine bottle manufacturers don’t need to pack the wine bottle in plastic or paper to mark the information of the wine. Instead, they can engrave the patterns and information that need to be displayed onto the glass bottle directly. Laser engrave glass wine bottles can help bottle suppliers save a lot of packaging materials, and the wine bottles are easier to recycle and reuse, which is more environmentally friendly. In addition, laser engrave glass wine bottle produces a unique texture on the bottle, making it more advanced and beautiful.

Laser Engrave Glass Vases

Another typical application of laser engrave glass is laser engrave glass vases.

Glass is one of the main materials to make vases. People use glass vases to collect beautiful flowers and decorate their living rooms, dining rooms and many public places. Glass vases can be used to store flowers or as decorative ornaments.

The laser engraving machine can engrave patterns or characters on the side and bottom of the glass vase, increasing the artistic value of the vase. You can also design a personalized laser engrave glass vase as a perfect birthday gift or anniversary gift for your family or friends.

Laser Engrave Glass Keychain

The laser engraving technology also finds its popularity in making exquisite glass keychains. People like to carry nice keychains with them. And a keychain with special meaning is more worthy of collection. Laser engraving technology can engrave personalized patterns on glass keychains, such as family names, thank you words, character outlines, pet portraits, etc. You can give this specially customized laser engrave keychain as a gift or souvenir to the people you love or you want to give thanks to. What’s more, laser engrave glass can realize millimeter-level engraving and can engrave small-sized workpieces with very good engraving accuracy and minimal error.

Laser Cut and Engrave Glass Plaque

Glass plaques are used to recognize and reward employees, celebrities, and individuals or companies that have made outstanding contributions in a certain industry. The use of laser cutting technology and laser engraving technology can make exquisite glass plaques. Firstly, laser cut the base and body of the plaque, and you can get a beautifully curved glass plaque. Then, use engrave the required patterns on the plaque. No matter what pattern or font, laser engraving can do it. The laser cut and engrave glass plaque has a beautiful shape, delicate engraving texture, and no scratches or cracks. It is very suitable for various employee recognition activities and awards activities.

Laser Cut and Engrave Glass Coasters

Glass coasters are common daily necessities. The laser can be used to cut the coaster and will not cause any cracks on the cutting seam. In addition, engraving exquisite patterns or words on the glass coaster can increase the aesthetic value of the coaster. Laser engraving technology can realize free engraving of glass coasters. The laser is very precise and can achieve fine details and line engraving. For coaster sellers, they can expand their business and increase customers by providing free pattern customization services. The laser will not leave scratches on the glass surface when engraving the glass coaster. It only engraves the required pattern at the correct position.

Laser Cut Glass Precautions

The precautions of laser cut glass mainly includes safety precautions and operation precautions.

Laser Cut Glass Safety Precautions

- Before operating a CO2 laser cutting machine, be sure to wear protective glasses and gloves. In this way, you can protect yourself from any laser damage, and also prevent the debris generated by the glass explosion during the cutting process from causing personal injury.

- Do not look directly at the laser beam after the laser cutting glass process. Don’t get too close to the laser cutting head when it is running.

- After processing the glass, keep wearing gloves for the next step of processing the glass.

Laser Cut Glass Operation Precautions

- Choose the right CO2 laser cutting machine and configuration for the glass material you need to process. This includes but is not limited to choosing a suitable laser power according to the thickness of the glass, choosing a CO2 laser cutting machine with a large enough worktable according to the size of the glass, and so on.

- If you want to engage in glass engraving, you need to pay attention to choosing the appropriate laser power. It is best to make a sample to test the engraving effect before the real processing.

- During the cutting process, try to reduce the number of repeated cuts to ensure that the cutting accuracy meets the requirements.

- To make the glass break smoothly, it is necessary to mechanically draw a small initial crack on the cutting line before laser cutting, and the crack should not be too deep or long.

- Precisely control the laser power, and be careful not to make the glass surface reach the softening point. For different types of glass materials, the laser beam does not necessarily focus on the surface of the glass but focuses on a few centimeters below the glass plate to make the spot elliptical.

- To choose a suitable cutting speed, it is necessary to ensure that enough laser heat forms a stress pattern distribution on the glass without melting the glass.

- In the process of laser cutting glass, the melting and vaporization of the glass will produce a certain amount of dust. So it is necessary to keep the workspace ventilated.

Recommend Two Glass Laser Cutting & Engraving Machines

After learning about the characteristics, applications and precautions of laser cut glass, now it’s time to get a glass laser cutting machine and make the glass products you want to make. DXTECH has rich experience in the research and manufacturing of glass laser cutting machines. The following two glass laser cutting machines can help you process glass and realize your design and creativity.

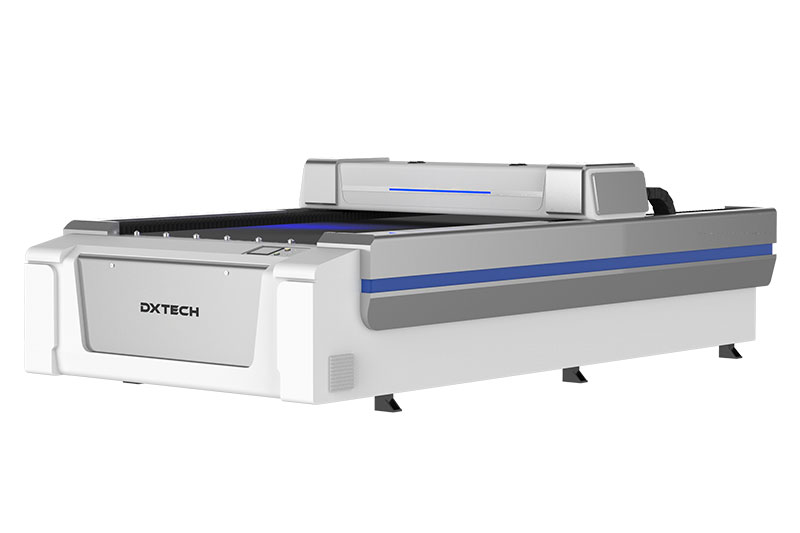

1325 Glass Laser Cutting & Engraving Machine

This 1325 CO2 glass laser cutting & engraving machine is one of the top-selling machines of DXTECH. Its working size is 1300*2500mm. The working size can be customized according to the processing needs. In addition, the machine is equipped with world-class components which have stable performance, high engraving accuracy, and long service life.

This 1325 glass laser cutting & engraving machine has the following advantages:

- Open-type machine structure, humanized design, very easy to operate.

- The CO2 laser tube has stable performance and long working life.

- Japan Omron electric component has high power supply efficiency.

- Taiwan high-precision guide rails ensure the machine works smoothly and accurately.

- The stepper motor has stable performance and superior characteristics of instant start and emergency stop.

- The intelligent water cooling equipment has a good cooling effect and long service life.

1390 Glass Laser Cutting & Engraving Machine

This 1390 CO2 laser cutting and engraving machine is suitable for small-scale glass engraving work, such as glass cup carving, glass bottle engraving, glass gift engraving, glass handicraft engraving and so on. This small laser engraving machine is affordable and has stable engraving performance. Even people who are new to laser engraving can learn it quickly. This 1390 glass engraving machine is the top choice for individuals who are engaged in glass designing and engraving.

The main features of this 1390 glass engraving machine are:

- Equipped with a fully enclosed laser protective cover, it can intimately protect users from laser damage. And the working environment is tidier and cleaner.

- The laser head has good quality, low noise, good processing effect. The processing accuracy can reach 0.02 mm.

- Equipped with Taiwan high-precision guide rails, the machine runs more stable and the machining accuracy is guaranteed.

- The stepper motor has stable performance and has the superior characteristics of instant start and emergency stop.

Conclusion

Laser technology brings a new revolution for the glass processing industry. Compared with traditional mechanical glass cutting, laser cut glass has the advantages of high cutting efficiency, high precision, low maintenance costs, no cracks, and no debris. Laser cutting and laser engraving technology have promoted the development of the glass processing industry. For glass processing companies, laser cut glass improves the product qualification rate, reduces labor costs and material costs, and increases corporate revenue. For individuals who are engaged in glass carving work, owning a glass laser cutting and engraving machine can help them easily process various glass products. Also, there is no restriction on engraving patterns by laser engraving glass.

If you need a glass laser cutting and engraving machine, you can contact us. We will recommend suitable machines to help you make glass products efficiently and precisely.

Hi DXTECH

I am an export engineering student from the Technical University of Denmark.

I am working on a project where I have to design a lamp and theoretically produce, ship and sell it.

So i was wondering if you had a general price on this machine of yours: 1325 CO2 glass laser cutting.

Thank you very much.

Regards

Yasemin