In the metal processing industry, the aluminum is the main raw material. And the laser cut aluminum is an aluminum product that commonly used in various industries. Laser cut aluminum refers to aluminum products processed by laser cutting, engraving, and hollowing. It can be further processed into hollow doors and windows, stair handrails, screens, plaques, aluminum handicrafts, and various decorations.

The laser cut aluminum can be used in the exterior and interior decoration and modeling of buildings. People often see these aluminum laser products in airports, exhibition halls, subways stations, office buildings, shopping malls, and office buildings. Of course, the aluminum can also be engraved by using an aluminum laser engraving machine. And the laser engraving aluminum, especially for laser engraving anodized aluminum, is mostly used in electronic parts processing industries.

Why choose the laser machine to produce laser cut aluminum?

The laser cut aluminum has superior features better than aluminum processed by traditional mechanical cutters. The following introduces some unique features of laser cut aluminum and laser engraving aluminum.

Features of laser cut aluminum and laser engraving aluminum:

- The cutting seam of laser cut aluminum is fine.

The cutting seam of laser cut aluminum plate is generally from 0.1mm-0.2mm.

- Smooth cutting surface

The cutting surface of laser cut aluminum plate has no burrs and no dross.

- No mechanical deformation

The laser head does not contact the laser cutting aluminum plate and there is no problem with machining tool wear. The work-piece is not affected by the machining force.

- Small thermal deformation

The processing of laser cut aluminum or laser engraving aluminum plate is thin, fast, and energy concentrated. And the heat transferred to the aluminum material to be cut is focused on one point. Therefore, the deformation of the laser cut aluminum is none or very small.

- Material saving

The aluminum laser cutting machine adopts computer programming, can cut aluminum plates of different shapes as needed, without using the mold. And it improves the material utilization rate of aluminum plate, increases working efficiency, and saves a lot of material cost.

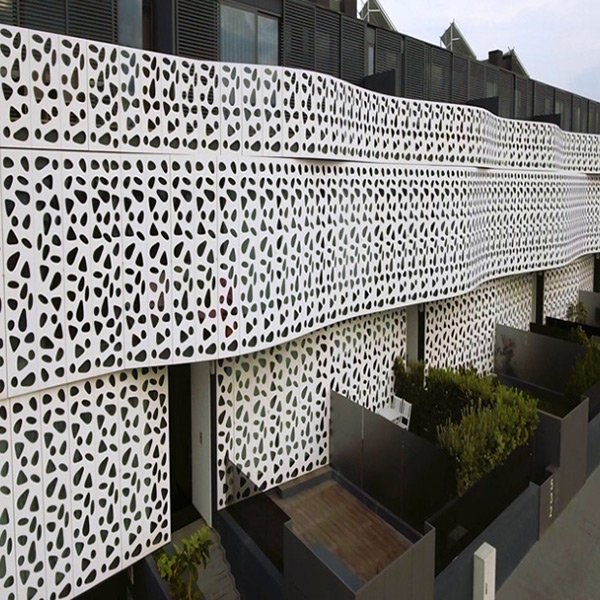

For example, the laser cutting thin aluminum plate processed by the laser aluminum cutting machine has a strong three-dimensional effect. Such laser cut aluminum also owns beautiful and precise patterns and has a more qualitative feeling. And the laser cutting aluminum plate is mostly used for interior and exterior wall decoration of buildings. It can provide shade, ventilation, and beautify the appearance of buildings, and also increase a lot of sense of art. In addition, the hollow aluminum plate can be 100% reusable, which is of environmental protection.

The laser power is high density, and the aluminum material absorbs the laser and melts or vaporizes. Even the metal materials with a high melting point, high hardness, and brittleness can be processed by laser aluminum cutting machines.

Features of the aluminum laser cutting machine:

- Laser cut aluminum processing is to use the energy of the laser to reach a very high energy density at the focal point after being focused by focusing. And the aluminum material absorbs laser to heat and vaporizes to achieve the cutting process. Laser cutting processing does not require traditional tools. The laser is like an “invisible knife”, which has the characteristics of fast processing speed and small material deformation.

- The spot diameter of the laser beam of the aluminum laser cutting machine can be as small as microns. And the time of processing the laser cut aluminum can be as short as possible. At the same time, the continuous output power of the high-power laser of the aluminum laser cutting machine can reach the kilowatts to ten kilowatts. Therefore, the laser aluminum cutting machine is suitable for both precision processing and for large-scale laser aluminum plate processing.

- The laser beam of the aluminum laser cutting machine, combined with precision machinery, precision measurement technology, and computer, can achieve a high degree of automation and high processing accuracy.

How is laser cut aluminum produced?

The aluminum laser cutting machine generates the laser to irradiate the aluminum with a focused high-power-density laser beam. The laser will quickly melt and vaporize the aluminum material. At the same time, the molten material is blown away by the high-speed airflow coaxial with the beam to realize the cutting of the aluminum. Thus the laser cut aluminum with designed patterned is produced. Moreover, the laser has the characteristics of fast processing speed and small material deformation.

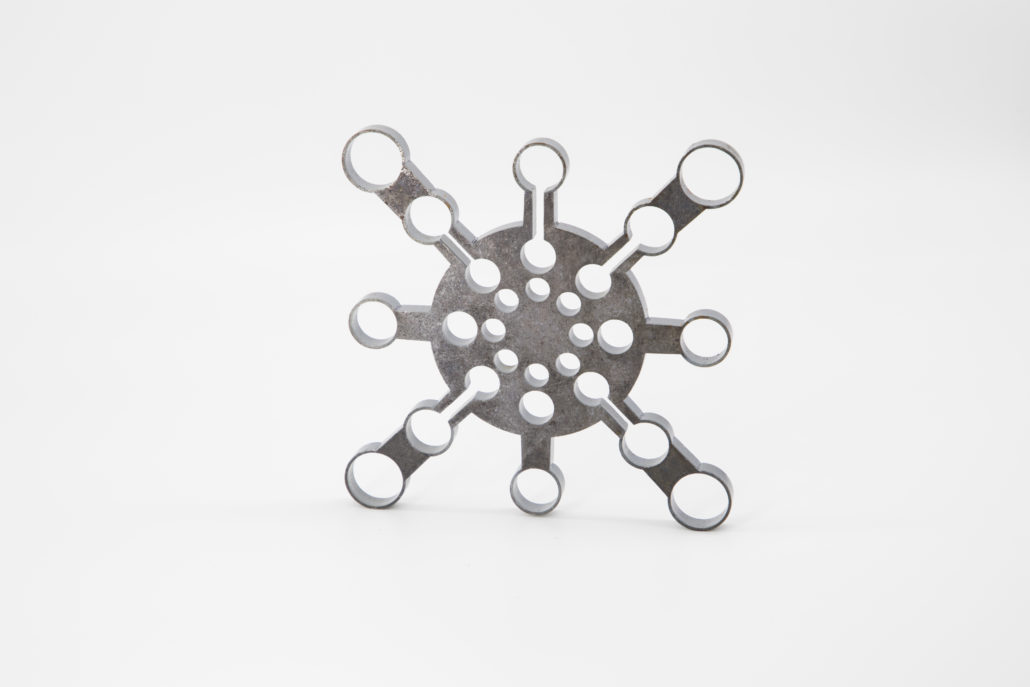

Using an aluminum laser cutting machine can complete the processing of laser cut aluminum and laser engraving aluminum. The machine cuts aluminum into different shapes and makes various exquisite patterns and letters. Usually, the aluminum laser cutting machine is mainly composed of three parts: computer, main machine, and controller. And the users can design the sizes and patterns of the laser cutting aluminum plate through the laser processing software on the computer. They can also set up the depth and position of the aluminum laser cutting. The design information of laser cut or laser engraving aluminum will be automatically transmitted to the controller. And the controller converts this information into signals that can drive the motor. And then it controls the laser head to generate the engraving or cutting path.

Meanwhile, the laser head configured according to the material on the aluminum laser cutting machine rotates at a high speed. And the laser will cut the aluminum plate based on the program instructions. After processing by aluminum laser cutting machine, the aluminum can be hollowed and made into different shapes and design patterns. More importantly, the laser cut or laser engraving aluminum has smooth and tidy edges, without further processing, realizing automatic laser aluminum processing.

Typical application of laser cut aluminum and laser engraving aluminum

Laser cutting aluminum plate for building decoration

The laser cutting aluminum plate is processed by using a fiber laser aluminum engraving machine through a series of processes. Through the laser cutting and engraving software, the users of aluminum laser cutting machine input the parameters into the machine. And the laser aluminum machine will automatically cut and hollow aluminum and engraves various types of graphics as required precisely. Additionally, the aluminum laser cutting machine can hollow aluminum plates into different shapes, such as circle, square, triangle, and diamond, etc.

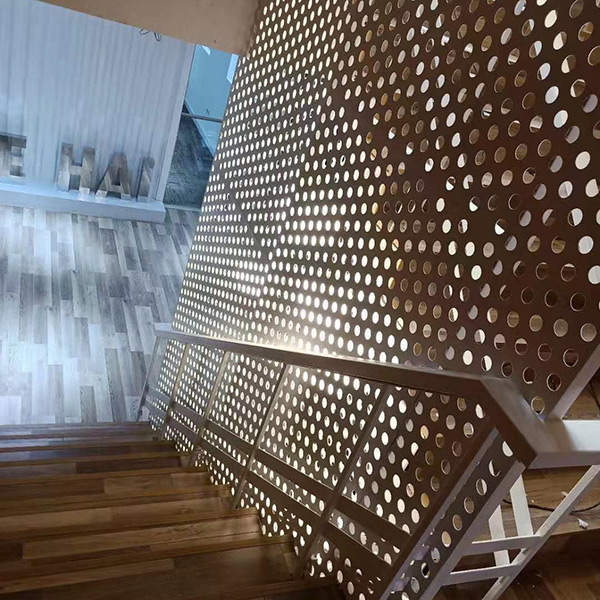

Through the hollowing and cutting by aluminum laser cutting machine, the laser cut aluminum plate can be used for building decoration industry. And the finished laser cut aluminum and laser engraving aluminum plates have smooth and tidy edges, no need for secondary processing. Additionally, they also own artistic modeling characteristics.

The laser cutting aluminum plate, especially the laser engraving anodized aluminum after the processing of the aluminum laser cutting machine. And it has good resistance to corrosion, excellent weathering resistance, and long service life. Moreover, using the laser cutting machine to process aluminum plates does not require making molds for different patterns and shapes. This feature improves processing efficiency and reduces production costs.

The laser cut aluminum plates with different patterns show classic, elegant, and fresh style, making the monotonous architecture become lively. And gradually it has become the noble and representative decoration products in the building decoration industry.

Aluminum curtain wall:

The single building decoration product can no longer meet the needs of engineering contractors. They choose the aluminum curtain wall that more suitable for the development of the times to replace traditional decoration products. And the aluminum curtain wall is usually made of laser engraving anodized aluminum.

The aluminum curtain wall has become a new type of decorative material because it has the following characteristics.

- The laser engraving anodized aluminum is the raw material of aluminum curtain wall. It can be customized according to engineering needs. And the shape, patterns, and style can be diversified by using an aluminum laser engraving machine. This feature makes many buildings break the single style, and the designer’s creativity can be well displayed.

- The laser engraving aluminum curtain wall is light in weight, has high strength, and stable functions. Furthermore, the laser engraving anodized aluminum can prolong the life of the building and enhance the sound insulation effect.

- Through the feedback of the users, the installation of the laser engraving aluminum curtain wall is simple and convenient. And it can greatly increase the time cost.

Functions of laser cut aluminum curtain wall:

The laser cut aluminum plate is beautified with the cutting, engraving and hollowing process of the aluminum laser cutting machine. And the laser engraving aluminum can give people a stronger visual and psychological impact. It can relieve the depression caused by the closed space, which can broaden the field of vision, and increase the perception of space. The hollowed laser cut aluminum plate has a variety of pattern combinations. And the cutting patterns of laser engraving aluminum can be processed according to customer requirements. The users can cut and drill holes of various shapes on aluminum materials by using a aluminum laser cutting machine. In short, the laser cut aluminum can meet customers’ individual pursuit of aluminum board decoration very well.

The laser engraving anodized aluminum plate has the characteristics of resistance to acid rain, salt mist, and various air pollutants. And it is also resistant to cold and heat excellently. Therefore, the laser engraving aluminum is widely used in the exterior wall and interior decoration modeling of buildings. It plays the functions of providing shading, ventilation, and beautifying the appearance of buildings. These functions make laser engraving aluminum curtain walls become a good substitute for traditional decorative materials. The laser cut and laser engraving aluminum curtain wall are not only a good substitute for traditional decorative materials. They also maximize the utilization of resources. Hence, more and more engineering companies have chosen the laser engraving anodized aluminum to produce curtain walls.

Laser cut aluminum for aerospace industry

The laser cut and laser engraving aluminum can also be used in the aerospace industry. For example, it has been applied in aircraft manufacturing, spacecraft series, satellites, and so on. As the aluminum plate, especially for the laser cutting thin aluminum, has light in weight and high strength. Furthermore, the laser cut aluminum is also convenient for processing and relatively cheaper. And thus, it is taken as the main structural material for a lot of aircraft facilities.

Laser cut aluminum for shipbuilding

The laser cut aluminum has been used in the shipbuilding industry for a long time. The low density, good strength, high rigidity, and corrosion resistance of laser aluminum products are more suitable for shipbuilding. And the processing cost of laser cut and laser engraving aluminum is comparatively lower, it has economical efficiency. From the view of ship designers, the ships made from laser cut aluminum alloy can reach to high speed and have a long working life.

Laser cut aluminum for automobile manufacturing

As the lightweight progress of automobile is speeding up, the laser cut and laser engraving aluminum plate is increasingly used as the new substitute material in the automobile manufacturing industry. The use of laser cut aluminum alloy for automobile parts can guarantee normal driving, and also greatly reduce automobile driving, and achieve the purpose of energy conservation and emission reduction.

Laser engraving aluminum in electronic parts processing

The laser engraving anodized aluminum is widely used in the processing of electronic products. The reason is it has good wearing and corrosion resistance property.

As the electronic components require good heat dissipation requirements, the laser engraving aluminum plates have been widely used. Some customers require that the surface of aluminum needs to be printed with letters or patterns. The traditional silk-screen printing method has the defects of unclear effect and poor corrosion resistance, and eventually leads to discoloration. While choosing an aluminum laser engraving machine can solve these problems. The aluminum laser engraving machine has no cutting force, no deformation in processing; no tool wear, good material adaptability.

The shells of most of the electronic products are made from the anodized aluminum. Using a laser engraving machine for anodized aluminum can engrave and mark LOGO, serial number, production information, bar code, and two-dimensional code on the electronic product shell. The engraving effect of the laser engraving anodized aluminum is clear, exquisite and beautiful, and has high precision. Furthermore, the laser engraving aluminum processing also improves the product grade and increases the added value of the product. At the same time, the laser engraving anodized aluminum can avoid further oxidation of the surface of the aluminum plate.

Advantages of DXTECH’s laser aluminum machines

DXTECH’s aluminum laser engraving machine and aluminum laser cutting machine have high flexibility, and fast cutting speed. They also own high production efficiency, and short product production cycle. These laser aluminum machines increase production efficiency for customers and obtain considerable profits. And they are computer numerical control, easy to operate, and high material utilization. According to the users’ different needs, the aluminum laser engraving machine can also be used to engrave aluminum into the laser engraving aluminum products with various patterns or mark various letters or graphics on it.

DXTECH has a strong technical force, production personnel and technical engineers have received good professional technical training, dedicated to serving all customers, providing aluminum laser cutting machine and laser engraving machine that meet customer requirements.