With the continuous changing demanding of the market, the laser cutting technology finds wide applications in industries. This technology is capable of highly precise and versatile. Plus, the laser cutting technology is continuously developing into being higher precision and better flexibility.

To give the fullest benefits of the laser cutting technology, the laser cutting machine is indispensable. Such a machine mainly comes into two types, namely the fiber laser vs co2 laser. Yet, there are many differences and similarities between fiber laser vs co2 laser. Hence, if you are gonna purchase the suitable type of laser cutting machine for your current project or long-term vision, it is wise to have knowledge of these two machines.

Today, this article just exactly serves as your requirements. It gives a detailed introduction on difference between fiber and CO2 laser cutting machine at the following aspects: definition, pros and cons, four performance comparison, working way, application, and future trends.

Ⅰ: Definition of Fiber Laser vs CO2 Laser

What is Fiber Laser Cutting Machine?

The uniqueness of a fiber laser cutting machine design rests on its low cost of maintenance, and even maintenance-free. This all owes to its superior quality. Plus, its exclusive fiber system boasts a very long service lifespan at least up to 25,000 laser hours. The fiber laser cutting design is ideally great for handling laser marking and metal marking ( such as engraving, annealing, and high-contrast plastic markings ). Besides, it is very suitable to process such materials as coated metals, plastics.

What is CO2 Laser Cutter?

The CO2 laser cutter is the most common cutting machine at the market. This laser cutting design features the unique laser beam. The laser beam consists of a gas mixture with the CO2 being major. From the perspective of the macroscope, CO2 is best great for handling non-metallic materials and the majority of plastics. Detailly speaking, the COS laser cutting design machine is apt to tackle such materials as wood, glass, textiles, plastics, foils & films, leather, stone.

Ⅱ: Four Performance Comparision: Fiber Laser vs CO2 Laser

Power Consumption:

Different between fiber and CO2 laser cutting machine manifested from this aspect, is when comparing with the CO2 laser cutting machine, the fiber laser cutter needs much less electricity supports. For example, running at maximum power at the 4kW, fiber laser cutter, and its chiller will consume about 18 kW of electricity. In contrast, the CO2 laser cutter and its chiller will run at the expense of 70 kW power consumption.

Operating Cost:

If we want to know the difference between fiber and CO2 laser cutting mahcine, we should know that the fiber laser cutter is half than that of a CO2 laser cutter in terms of the operating cost. The reason is that the former features lower power consumption and higher electrical efficiency.

Edge Quality:

As the thickness of processed material enhances, the cutting results will vary along with. There is a concerned difference between fiber and CO2 laser cutting machine. The CO2 lasers can show better edge cutting effects on the thick stainless steel and aluminum workpieces. Yet, the fiber lasers can’t attain the same effects. One of the influencing factors is the consumption of the higher auxiliary gas. The fiber lasers will use over 30 percent to assist gas. wondering the reason for such a situation, the smaller spot size might be the best answer.

Cutting Speed:

To begin with, both the fiber laser cutter and CO2 laser cutter can process many same materials. However, the difference between fiber and CO2 laser cutting machine is that the former can produce better cutting results when handling some metals, i.e. copper, brass, and aluminum. Secondly, both two laser cutters can mark on the aluminum. But, the CO2 laser cutter will take more time to pierce a hole than the fiber laser cutter. Finally, when processing the stainless steel with nitrogen, the fiber laser cutter is much evidently faster.

Ⅲ: Pros and Cons: Fiber Laser vs CO2 Laser

Fiber Laser Cutting Machine

Pros:

Cheaper Buying Costs: After the spreading of solid-state laser technology, the system costs have also seen a continuous decrease. Let us take the domestic fiber laser cutting system as an example. Such a multiple functional fiber laser cutting system can be available at a relatively reasonable price of less than 300K.

Time-Saving: The fiber laser machine can be equipped with two interchangeable tables. In such platforms, all materials are conveyed automatically without labor efforts. In this way, there will be a great decline in the tedious and mechanical work and save a lot of time.

Speed: When processing the thin materials, the fiber laser cutter machine is much faster than the CO2 laser cutter. The high-speed attributes to the easy absorption performance of the laser when cutting with Nitrogen (fusion cutting).

Cons:

Thick Material Finish: The fiber laser cutter is relatively less effective than the CO2 laser cutter in handling the thicker materials. CO2 laser cutter is more penetrating in the handling of finishes, especially making from stainless steel and aluminum.

Laking Flexibility: In comparison with the CO2 laser cutter, the fiber laser cutter is evidently weaker in the handling of a wider range of materials, in particular nonmetals. As the booming of the fiber cutting technology, the fiber laser cutting machine indeed can cut many metals, i.e. brass and copper. Yet, the fiber laser cutter still confronts many limits in practical utilization, especially in processing nonmetal materials.

CO2 Laser Cutter

Pros:

Wide Applications: From the perspective of macroscope, the COS laser cutting machine finds wide applications in the processing of various materials, i.e. wood, glass, textiles, plastics, foils & films, leather, stone. Yet, speaking exactly, the CO2 laser cutter could generate better cutting effects on the plate stainless and aluminum workpieces in the practical application.

Flexibility: CO2 laser cutter can be extremely flexible in a wide range of laser application projects, covering non-metals.

Long-established Reputation: The CO2 laser cutting technology has appeared for around 30 years. And correspondingly, the CO2 laser cutter also appears in the market up to over 30 years. With the test of time, the CO2 laser cutter will be a good assurance for a user.

Cons:

Higher Operating Costs: The CO2 laser cutter equips with the CO2 Resonator, Blower, chiller, and other high power-consuming components. Therefore, its power consumption registers 70% higher than other cutting machines.

Maintenance: All of the above-mentioned components of the beam path delivery system require maintenance which can not only be disruptive to manufacturing but also very costly.

Highly Sensitive: The CO2 laser cutter is very sensitive. If you remove slightly the reflecting mirror that focuses on the laser, there is a need to realign. Moreover, this work must be conducted by an expert. Besides, the CO2 laser cutter cannot be compatible with reflective metals. The beam emitted from such metals would cause irreparable damage to the machine.

Ⅳ: Working Way: Fiber Laser VS CO2 Laser

How Fiber Laser Cutting Machine Works?

The fiber laser cutting machine boasts a row of diodes. These diodes could emit a beam of light, which then is transmitted via optic cables and gets amplified there. There are rare earth elements in the cables, which can amplify the light. Finally, the reflecting mirror focuses the light to form a beam of laser for cutting.

How CO2 Laser Cutter Works?

At the beginning of the cutting process, the CO2 laser cutter forms a light beam. And then, such a beam of light will be directed toward the outlet via the reflecting mirror. On its way, the focusing lens serves as a resonator that forms the light energy in the beam. After the forming of the beam, the nozzle of the cutting head leads the beam of light onto the working piece. The resulted beam of light can melt the various metals and keep the cut edge clean simultaneously.

Ⅴ: Future Trends:

Continuing with the above contents, let us have an outlook for future development. Although the majority of the industries are still employing CO2 lasers, fiber laser cutting machine began to boom in the market. Now, there is a growing number of businesses that turn to purchase the fiber laser cutting machine.

The fiber lasers have fewer mobile components and much less adjustments to do. That means much less maintenance costs than the CO2 laser cutter.

But, that does not mean that the CO2 lasers are totally outmoded. When processing thicker materials of 10mm, the CO2 lasers will produce more better edge quality.

On the whole, the fiber lasers see a promising future as a latter comer. One of the determining element is that it is friendly to the atmosphere.

Ⅵ: Applications: Fiber Laser VS CO2 Laser

Six Applications of CO2 Laser Cutting Machine

The CO2 laser cutting machine finds wide applications in the current industries. The following are its seven main application fields.

1. Acrylic Processing: The CO2 laser cutter of 100W can cut the acrylic as many as 3/4 inch ( about 18mm ) at one time. While, the CO2 lasers can process the acrylic as many as 11/4 inch ( namely 31mm ). When dealing with the thin materials, the CO2 laser with dual head is a wise choice for the enhance in the production volume.

2. Architectural Industry: In the architectural industry, the thin acrylics, mat-board, and wood are all commonly available materials. When processing such materials, the power and speed of the machine should be kept at an extremely precise extend. Hence, it is critical for building customers to choose a suitable machine.

3. Wood Cutting: As the wood is different, so is the power of the machine. Speaking in detail, the CO2 laser of100W can cut the wood of 3/4 inch and the CO2 laser of 200W can cut the wood of 1/4 inch. Moreover, the CO2 laser of 100W is also ideally great for processing the 6mm MDF decoration board.

4. Fabrics and Embroidery Processing: In the course of cutting, you can normally get materials that feature brown edge. The smaller volume of cutting is controllable. But, when cutting the materials stacking, materials are likely to stick together. Given the above facts, a CO2 laser of 40W or 60W is the optimum to perform perfectly such crafts working.

5. Paper/Foils Converting: Web converting applications means a process in which you can slit, perforate, and score the paper products, foils, or composites. With a CO2 laser, you can cut or mark precisely these materials at high speeds.

6. Advertising Industry: In the advertising industry, there are many situations or occasions in which the product customization is necessary. The traditional processing method is obviously out of fashion. While, the CO2 laser cutter catches up in the market. No matter adopting what kind of designs, the CO2 laser can provide high-quality metal products for the purpose of advertisement.

Six Applications of Fiber Laser Cutter Applications

1. Decoration Industry: As the fiber laser cutter is flexible in the cutting of many complex graphics, it has been extremely popular among the decoration companies. When there has an order requiring special design, the required materials can be immediately cut out after the finish of CAD drawing.

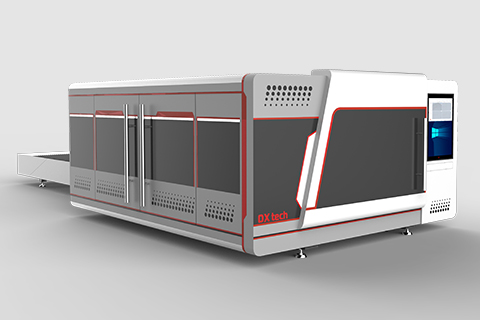

2. Sheet Metal Cutting: In modern metal processing industries, requirements are increasingly demanding for the precision and productivity in the processing of metal sheets and pipes. DXTECH fiber laser cutters can offer reliable and highly efficient cutting results. You could also view this guide to get familiar with the pros of our fiber laser cutting machine.

3. Automobile Industry: The fiber laser cutting machine could ensure outstanding precision and efficiency, highly improving the productivity and safety of automobile components. It finds a wide application in cutting many metal, such as exhaust pipes, brakes, car doors, tires, etc.

4. Kitchenware Industry: Now, with the improved living standard, people become more and more demanding for the design of home kitchenware. Hence, kitchen products embrace a promising market all around the world. The fiber laser cutting machine is ideally apt for processing thin stainless steel. The fiber laser cutter features the fast speed, high precision, good cutting results, and so on. To some degree of extent, it is well-performed enough to customize and design personalized products.

5. Lighting Industry: Nowadays, everywhere seen outdoor lamps mostly consists of large metal pipes in different cutting types. The traditional cutting method is relatively not efficient and can not offer personalized customization service. Equipped with high-quality metal plates and pipes cutter, the fiber laser cutting machine rightly represents a perfect solution to the problem above mentioned.

6. Fitness Equipment: In recent years, people pay more and more attention to the physical health. Correspondingly, the public fitness equipments have witnessed a rosy future. In other words, the demand for the fitness apparatus becomes larger and larger. The introduction of the fiber laser cutter is undoubtedly a blessing for the booming fitness industry.

Conclusion

We know the differences between fiber and CO2 laser cutting machine from this article. As one of the leading laser cutter manufacturers, DXTECH has been always devoted to the development of the first-class CO2 vs fiber laser. When there is a need for you to purchase a machine, DXTECH will be able enough to come up with the right solution. Here attach an ultra link about the best laser cutter for small business 2020 ( https://dxtech.com/fiber-laser-cutting-machine-vs-co2-laser-cutter/ )for your reference. If you want to learn other more detailed information about co2 vs fiber laser, please leave your comment below or contact us directly.