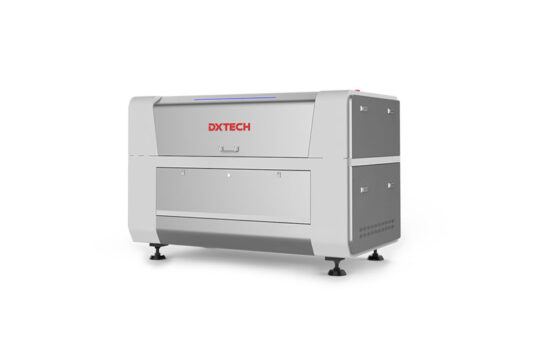

Laser Engraving Machine

Laser engraving machine, as the name implies, is an advanced laser equipment that uses laser to engrave materials. The laser engraving machine uses the thermal energy of the laser to engrave the material. The laser generator in the laser engraving machine is the core.

show more

According to different laser light sources, engraving machines have two kinds of types, namely CO2 laser engraving machines and fiber laser engraving machines. According to different processing materials, the engraving machine comes in various types, such as laser engraving machine for wood, laser engraver for metal. If you need the laser engraving machines above, we can provide customized services.

Laser engraving machine can engrave various non-metallic materials, such as wood, paper, leather, cloth, epoxy resin, acrylic, wool, plastic, rubber, ceramic tiles, marble, crystal, jade, bamboo products. And it can also process various metal sheets.

Therefore, the laser engraving machine finds various applications in various industries, such as kitchen sheet metal cutting, advertising words, large-scale truncation, clothing proofing, leather industry, footwear industry, decoration industry, furniture industry, packaging, printing industry, model industry, craft gift industry and so on.

show less

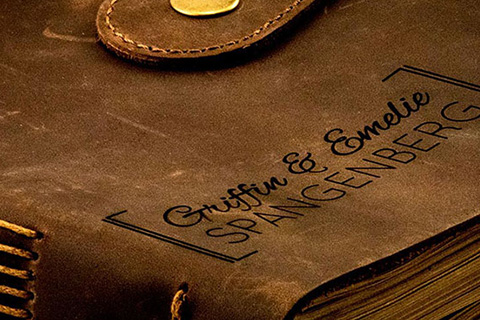

CO2 Laser Cutting And Engraving Samples

CO2 laser cutters are great for cutting and engraving non-metallic materials. CO2 laser engraving machine can cut and engrave materials including metal: low carbon, steel, aluminum, titanium, and alloy. Non-Metallic: Wood, Acrylic, Paper, Fabric, Epoxy, Resin, Plastic, Rubber, Crystal, Leather, Stone. CO2 laser cutting machines are widely used in clothing, leather, fabric toys, computer embroidery and cutting, electronic appliances, models, manual technology, advertising, decoration, packaging, printing, paper products, and other fields.

We provide free proofing, welcome to consult.

DXTECH Quality Assurance

2 years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Delivery case

Specifications

| Brand | DXTECH |

| Name: | Co2 Laser Cutting Engraving Machine |

| Working area | 1300mmx900mm, optional: 600x900mm, 1600x1000mm, etc.1300x2500mm |

| Laser power | RECI 130-150W, optional: 80W, 100W, 150w,180W,220v,etc |

| Laser type | Sealed Co2 laser source |

| Cooling | Water cooling and protect system |

| Cutting speed | 0-30000mm/min |

| Cutting thickness | 0-25mm acrylic (others determined by materials) |

| Position system | Red dot |

| Support Graphic Format | DST, PLT, BMP, DXF |

| Motor&Drive | Stepper |

| Working voltage: | 220V, 50Hz |

| Position accuracy | ±0.05mm |

| Working table: | Up and down working table ;Blade platform |

| Packing: | Wooden box |

| Other | Air Pump, Exhaust Fan, Water Pipe, Toolbox, Focus Mirror, Reflector |

A laser engraving machine is the equipment that uses the thermal energy of laser to engrave the suitable materials. It mainly contains three parts, i.e. the laser, the controller and the working table.

The laser engraver is different from the mechanical machine and other traditional manual engraving methods. This machine adopts computer numerical control technology as the basis and takes laser as the media of processing. And it uses laser beams to make permanent marks on the surface of various materials. The materials melt and vaporize physically under the laser engraving irradiation, resulting in engraving marks. As it is non-contact processing, it will not cause mechanical deformation or damage on the work-piece.

The laser engraver has many types. Nowadays, the most engraver is CNC laser engraver as a console mod referencing Fiber laser engraver and CO2 laser engraver. The smaller engraver such as mini laser engraver also includes different types. Portable laser engraver is also called handheld laser engraver which can engrave cumbersome, enormous, immovable objects flexibly, and create a smooth, clean, high-contrast result. The new engraving technology referencing 3D printer with laser engraver combines 3D printing technology with laser engraving technique for 3D printer laser engraver.

Other types of engraver such as desktop laser engraver and DIY laser engraver is more personal, and support your own innovation products of laser engraving.

Application:

The engraver can use in various industries such as decoration, packaging, etc. And the laser engraved gifts are more popular engraving products in the market, and laser engraved photo with a clean surface, contrast pattern, and special design has become popular products among the laser engraved gifts.

The laser engraver tool lies in the laser and laser beam. The laser will generate a laser beam, and the optical mechanism will transmit such a laser beam and make it focus on the surface of the material. The material is quickly vaporized to form pits, with the action of the high-energy-density laser beam.

- The laser engraver uses a computer to control the X, Y, and Z axes to drive the laser head to move, and control the laser to switch as required. The image information processed by the software is designed previously and stored on the computer.

- When the laser engraver reads design information from the computer in sequence, the laser head moves back and forth from left to right and up to down along the design route. And finally, it forms a full piece of graphics or text, realizing the automation of carving.

- The laser processing technology belongs to non-contact processing. The tool of mechanical engraver carves through direct contact with the material. But it does not change the internal elements of the material. It relies on the high density of laser energy and has strong laser engraving operation performance.

Its features include a wide range of processing materials, and smooth cutting edges without secondary polishing. And it will generate no dust, and achieve fast processing speed, and high precision, less waste, and high efficiency.

According to the laser sources, it can be roughly divided into CO2 laser engravers and fiber laser engravers. But DXTECH also supplies the laser machines specially for some materials.

- CO2 laser engraver

CO2 laser engraver is mainly used for the processing of non-metal materials, such as wood, acrylics, paper and leather;

- Fiber laser engraver

The fiber laser engraver is mainly for the marking processing on metal materials. So the fiber laser engraver is also named metal laser engraver.

- Glass engraving machine

Specially designed for glass marking and engraving.

- Laser engraving machine for metal

This type of laser engraver for metal is specially designed for copper, aluminum and stainless steel, etc.

- Mini laser engraver

MINI laser engraver is also named desktop laser engraver, portable laser engraver or handheld laser engraver. And this CNC laser engraver is specially for marking or cutting small-sized work-piece.

Mini laser engraver includes portable laser engraver which is also known as handheld laser engraver, desktop laser engraver. The portable laser engraver or handheld laser engraver aims to deal with an enormous immovable object. It can engrave over the flat surface with a smooth, clean, and high-contrast engraving result.

Moreover, we also provide users with DIY laser engraver and customized CNC laser engraver, to realize all kinds of processing requirements.

Generally speaking, compared with mechanical engraver, the CNC laser engraver has a wider range of use. And the engraving accuracy is higher, and the engraving speed is faster.

Moreover, compared with the traditional manual engraving method, the laser for engraving can also achieve very detailed and lifelike engraving processing effects. This is not inferior to the level of hand-carving by experienced craftsmen at all.

The users need to follow the instructions of the laser engraver for safe operation. And it needs to start the laser engraver strictly in accordance with the laser start-up procedures. The operators must accept the training for technology and operation and are familiar with the structure and performance of the machine. They need to master relevant knowledge of the operating system.

- Before starting the machine, the operators should wear labor protection equipment as required. They must also wear protective glasses that meet the requirements near to the laser beam.

- After turning on the machine, the operators manually drive the machine along X and Y axes at low speed. This is to check whether there is any abnormality.

- Input the program for a new work-piece; and then, it needs to do a test run first and check the operation status.

- After the test run is Ok, the operators can place and fix the work piece on the working table, and start up the operation.

- During the process of working, the operators need to pay attention to observe the operation of the machine tool. This is to avoid accidents caused by the engraving machine beyond the effective travel range or collisions.

- During the operation, it needs to keep the laser, working table, and the surrounding area clean, orderly, and free of oil pollution. The work-piece, plates, and waste materials need to be stacked as required. Keep the fire extinguisher within easy reach. Do not place paper, cloth or other flammable materials near the unprotected laser beam.

- If there is any abnormality appears during processing, the operators must shut down the laser engraving machine down immediately. And then it needs to eliminate the fault or report to the supervisor.

Note: Before processing a new material, the operators need to make it clear whether the laser engraver can process it. This is to avoid the potential hazards of smoke and vapor.

After starting up the equipment, the operator shall not leave the position or ask others to supervise the operation without authorization. If it is necessary the operators have to leave for a while, the operator should stop the machine or turn off the power switch.

- It shall maintain the laser machines regularly, in order to increase the service life, save costs, and create greater benefits.

- When it finishes processing, it needs to turn off the power of the machine and computer. And the operators also need to cover the cap of optical lens. This is to prevent dust polluting the optical lens.

- The circuit is in a high voltage state when the laser engraver is at work. It needs to prohibit the unqualified staffs to maintain the laser machine.

- If the engraving effect is not good, please carefully check if any contamination on the surface of the focusing lens.

- Sometimes, the laser engraver is working continuously for many hours. And the lower surface of the focusing lens will absorb the dust in the air. It will affect the engraving effect. Therefore, it needs to clean the focusing lens after long-time operation.

- The users need to clean the cooling fins of the water chiller regularly to avoid excessive dust affecting the work. It also needs to replace the distilled water in the water tank every four months. Tap water or purified water should not be used.

- The first-stage filter of blower on the side of the optical lens of the reflector path must be checked at any time. There must be no water or oil, otherwise the lenses will be contaminated. The users must improve the air source to make it reach the standard.

- Check the protective gas of the external light path, freezer, cooling water circuit and air compressor once every week. And drain off the filter once a week.

The accessories directly affect the service life and overall processing performance of the engraving machine. Of course, the engraving machine parts are different, and the price of the engraving machine varies greatly. Normally, the higher the configuration of the engraving machine, the higher the price of the engraving machine. Therefore, cheap laser engraver may not meet our processing requirements. But it is not that the higher the configuration of the machine is suitable for us. We should choose the laser engraving machine according to our own processing needs.

The engrave kit, such as laser engraver software is very important for engravers. And the advanced laser engraver software usually has a high price if you want to buy it only. Nowadays, we provide high-quality affordable laser engraver with laser engraver software free. Once you bought the machine, you will have the laser engraver software. If you want to have 3D printing technology, 3D printer with laser engraver is a great choice, but it has a higher price than one which hasn’t.

The brand is the added value of a product. Products of well-known brands are often more secure in terms of product quality, assembly, production technology, and after-sales service. Therefore, the laser engraving machine is the same. For example, for the same functional laser engraving machine, the laser engraver price with a greater brand power will be slightly higher.

But high price not always means high quality. Nowadays, DXTECH provides various affordable laser engravers, whatever the size, the function you want to have, we have all types of engraver for you, and all of them are affordable laser engravers.

There are many types of laser machines, and their performance varies greatly. Therefore, processing performance is also one of the main factors affecting the laser engraver price. Normally, the processing is relatively complicated, and the laser machine with finer processing requirements is more expensive.

The processing material mainly involves the properties of the material and the processing thickness. Generally, the thicker the processed material, the greater the power requirement of the laser engraving machine. Therefore, the laser engraver price is higher. In addition, for some special processing materials, auxiliary gas is required to complete the ideal processing of the material. Therefore, the overall price is relatively higher.

| Types of laser engraver | Laser source | Price Range |

| Basic co2 laser engraver | co2 laser source | $600.00-$2,800.00 |

| Advance co2 laser engraver | co2 laser source | $3,250.00-$5,360.00 |

| Basic fiber laser engraver | fiber laser source | $4,400.00-$7,200.00 |

| Advanced fiber laser engraver | fiber laser source | $19,700.00-$59,900.00 |

| Glass laser engraver | co2 laser source | $2,000.00-$5,000.00 |

| Laser engraver for wood | co2 laser source | $2,000.00-$5,000.00 |

| MINI laser engraver | co2 laser source | $379.00-$399.00 |

There are various kinds of laser engravers on the market, so how to choose the best and affordable laser engraver? The following points may help you:

- Firstly, the users may investigate the market, and see what machine that others in the same industry are using. They can also judge the processing method or technology through the finished products.

- Secondly, please determine what materials to engrave mostly. As mentioned above, the CO2 laser machine is mainly for the processing of non-metal products, and the fiber laser machine focuses on metal materials.

- Thirdly, the users may consider the size of the materials for laser processing. It is about the choice of the size of the working table. But the users should notice that the large size of the machine is not necessarily good. Because the large-size equipment is of course more expensive.

If the work-piece is small, and the working table is large, the laser output some laser machines may become unstable. It will result in irregular depths on the same working table. Therefore, it is better to choose the most appropriate working table in combination with the size of the work-piece.

- Power of laser tube: The users can select appropriate laser tube wattage according to the material and the content of the engraving. For example, the engraving of acrylic and double-color boards do not require too large power. But the wood and stone engraving and cutting will require a higher-power laser tube.

- After-sales maintenance service: After-sales maintenance service is very important for the users. Some customers may purchase the laser engraver for the first time. And they may encounter operation questions or doubts during the operation process. If the suppliers offer good technical after-sales service, it will be very helpful for the continuity and efficiency of processing.

Nowadays, most engraving manufacturers provide affordable laser engravers with reasonable laser engraving mahcine price. The responsible engraving manufacturers provide low-cost laser engraver for sale at a reasonable price. The factors of the affordable laser engraver include not only the quality cost but the maintenance cost. If you find a machine with very low laser engraving machine price, it may do not a low cost laser engraver for sale.