Carbon fiber is also known as carbon fiber reinforced polymer (CFRP). This material is soft, light but has high strength. It has wide applications in aerospace, automobile, wind power generation and sports industries. And speaking of carbon fiber cutting, there are many methods to cut it while each method has some disadvantages. Carbon fiber laser cutting is an ideal cutting method and it is very effective in carbon fiber cutting. With fast cutting speed and good cutting precision, carbon fiber laser cutting has huge potential in various industries. For carbon fiber processing enterprises, laser cutting can be a long-term solution for business development.

In this article, we will introduce why carbon fiber laser cutting is so important. And hope you can learn something useful from it.

Introduction of Carbon Fiber

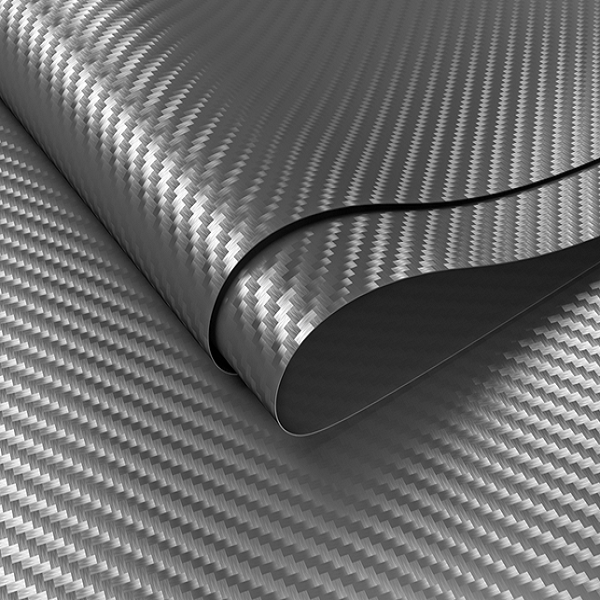

In theory, carbon fiber is woven from inorganic fiber and then bonded together by the polymer matrix material. This material contains more than 90% carbon element and shows high strength, high-temperature resistance and corrosion resistance ability. The carbon fiber material is an important member of lightweight materials and is gradually replacing traditional metal materials in many industries.

Carbon fiber has wide applications in many manufacturing industries such as aerospace, wind power generation, automobile and so on. It is an ideal material to make precision parts for airplanes, satellites, cars and medical equipment. Also, carbon fiber composite materials are very popular for occasions that have higher requirements for weight and mechanical properties. Some examples are aviation components, boats, wind turbine blades, sports goods, medical equipment, automobile parts, etc. Carbon fiber is not metal, while its properties are better than metal and the price is much lower. Many professionals predict that carbon fiber will play a more important role in the near future.

How to Cut Carbon Fiber?

Before using carbon fiber material to make any products, we need to cut it into a suitable size or engrave it per different requirements. There are mainly two methods to process carbon fiber: Mechanical processing and special processing.

Traditional mechanical processing is to use mechanical knives to cut carbon fiber directly. However, this method has many problems in the machining process, such as the high cutting temperature of tools, severe material wear, high maintenance cost, etc.

The special processing methods include laser cutting, ultrasonic vibration cutting and electric spark cutting which are playing an increasing role on various occasions. These processing methods have wide applications in a variety of industries. Among these special processing methods, carbon fiber laser cutting is the most widely used cutting method. The laser cutting machine cuts carbon fiber by generating a high-power laser beam and melting and vaporizing the materials. Laser cutting has the characteristics of non-contact cutting, fast cutting speed, high cutting precision and automatic operation. Laser cut carbon fiber sheet has a smooth cutting edge. Carbon fiber laser cutting is a high-end carbon fiber cutting solution.

What is Carbon Fiber Laser Cutting?

Carbon fiber laser cutting uses a CO2 laser cutting machine to cut carbon fiber. The principle of CO2 laser cutting is: laser generator generates a laser beam and the laser beam irradiates on the carbon fiber. And then the part of carbon fiber melts and vaporizes instantly and forms a narrow slit.

Laser cutting carbon fiber has many obvious advantages over traditional mechanical cutting:

Firstly, the laser cutter adopts an intelligent cutting control system. And the control system can optimize typesetting automatically and reduces material waste.

Secondly, laser cut carbon fiber sheet has a smooth cutting edge and there is little to no burr.

Thirdly, laser cutting has no wear and tear to the cutting head and material. And this greatly reduces the processing cost and improves the quality of products.

Moreover, laser cutting shows high cutting precision and little error. And it can meet the strict processing standard of precision parts.

Last but not least, laser cutting runs automatically. It’s easy to learn and operate for beginners. And it brings users a good processing experience.

Application Prospects of Carbon Fiber Laser Cutting

In many industries around the world, carbon fiber is playing a more and more important role. As an efficient carbon fiber cutting method, carbon fiber laser cutting has broad prospects in aerospace, automobile, sports, medical and other fields.

Carbon Fiber Laser Cutting In Aerospace Industry

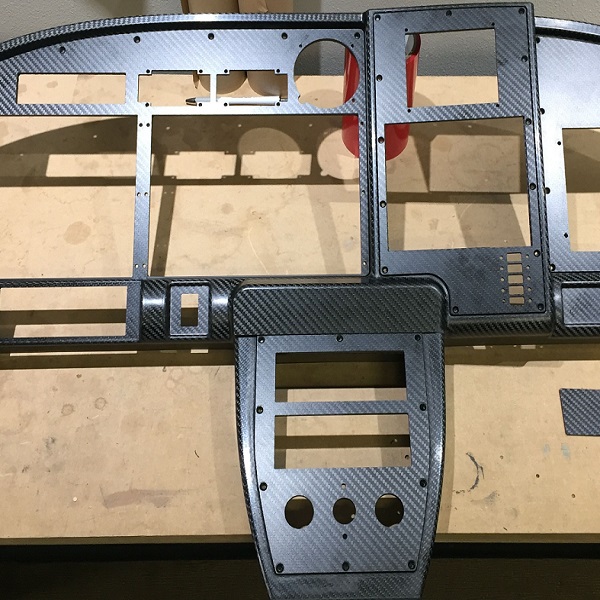

Compared with steel or aluminum, carbon fiber has a lighter weight and achieves 20% to 40% weight reduction for aircraft. It greatly reduces the fuel cost and carbon dioxide emissions of aircraft. Laser cut carbon fiber is widely used to make structural components of aircraft, rockets and satellites. For example, the avionics panel of aircraft can be laser cut by a Co2 laser cutter precisely. Compared with the mechanical cutting method, the laser cutting head has no contact with workpieces. There is no scratch and wear on the surface of carbon fiber material. This can meet the high requirement of the aerospace industry. In addition, the manufacturers of artificial satellites and rockets need laser cut carbon fiber to make antennas, brackets, engine shells, nozzles and other parts.

Carbon Fiber Laser Cutting In Automobile Industry

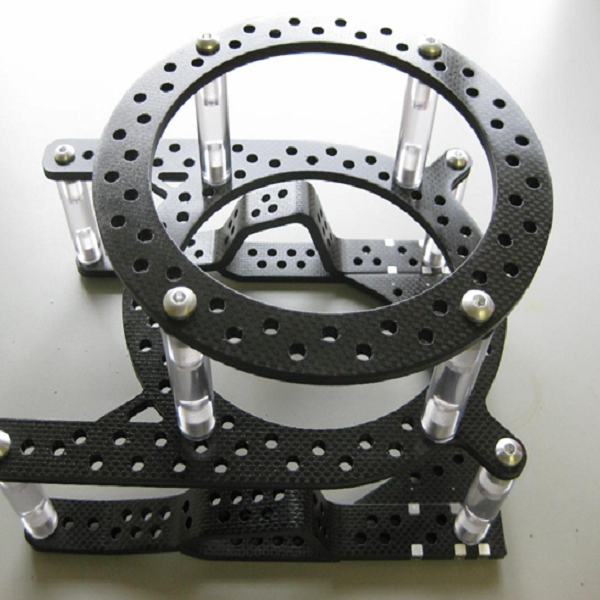

In the automobile manufacturing industry, some manufacturers have used laser cut carbon fiber to make structural parts, covering parts, interior parts and body for automobile manufacturing. For example, the chassis sheets of cars can be laser cut by a laser cutting machine with high precision. Laser cut carbon fiber auto parts greatly reduce the weight of cars and saves fuel costs. With the higher environmental protection requirements in the current world, light vehicles with laser cut carbon fiber parts are becoming more and more popular. And the laser cutting carbon fiber technology will get more and more applications in automobile manufacturing. Laser cut carbon fiber has huge application potential in the new energy vehicle manufacturing.

Carbon fiber laser cutting has many advantages in the manufacturing of carbon fiber car bodies and other car parts. The laser cutting is controlled by a computer, which is very suitable for the mass production of automobile parts. The carbon fiber cut by laser cutting has high strength and durability. And the laser cut carbon fiber sheet has a smooth and tiny cutting edge. The carbon fiber parts cut by laser are easy to install and assemble on cars.

Carbon Fiber Laser Cutting In Sports Industry

Laser cutting technology also has a broad application prospect in the sports industry. The laser cutting method can produce many types of sports goods. And laser cut carbon fiber sports goods are very popular among sports enthusiasts. The sports goods made with carbon fiber are resistant to wear and have a longer life. Laser cut carbon fiber sports goods are light and convenient to use. Compared with wood and plastic, carbon fiber sports goods are more durable. There are many types of laser cut carbon fiber sports goods in our daily life. Laser cutting can make carbon fiber rackets, carbon fiber skis, carbon fiber skateboards, carbon fiber bicycles, carbon fiber helmets, etc.

Carbon fiber laser cutting has obvious advantages over mechanical cutting. The non-contact laser cutting can protect the surface of carbon fiber from abrasion and improve the qualified rate of sports goods. In addition, laser cutting is automatic, simple and controllable. It can be used in the mass production of carbon fiber sports goods processing.

Carbon Fiber Laser Cutting In Medical Industry

The high-end medical equipment attaches great importance to the quality, stability and precision of the raw materials. Medical equipment made of laser cut carbon fiber composite materials has light weight, high stability and high strength. Moreover, laser cut carbon fiber can resist X-ray damage to patients. Laser cut carbon fiber can be used in medical equipment structural components such as X-ray tables, booms, head holders and so on. The laser cutting method has high processing precision and can meet the requirements of medical equipment parts processing accuracy. Besides, laser cutting has a fast cutting speed, which improves productivity for enterprises engaged in the mass production of medical equipment.

Advantages of CO2 Laser Cutting Machine

As carbon fiber is a kind of non-metallic material, a CO2 laser cutting machine is suitable to cut it and produce a good cutting effect. CO2 laser cutting machine has the following advantages in carbon fiber processing.

- Non-contact cutting

CO2 laser cutter replaces the cutting knife with a laser beam. The laser head has no contact with the material, so there is no wear or tear.

- Automatic processing

A CO2 laser cutter is controlled by software. It shows the characteristics of accurate positioning, high processing precision and automatic typesetting.

- High precision

CO2 laser cutter has high cutting accuracy, almost no burrs and no need for subsequent processing. This greatly reduces processing costs.

- Strong cutting power

CO2 laser cutting machine delivers high-density laser beam which can melt thick materials. The higher the laser power, the thicker the cutting depth. For instance, a 100W CO2 laser cutting machine can cut 5-20 mm non-metallic materials.

- Wide applications

CO2 laser cutting machine can process various non-metallic materials including carbon fiber, acrylic, paper, wood, leather, fabric, glass, crystal, etc. It can help many enterprises and individuals expand the business, save processing costs and labor costs and get more profits.

- Unlimited processing patterns

The movement of the laser cutting head is controlled by a computer, so there are no limits to the patterns. CO2 laser cutter can process both simple and complex patterns on the work pieces.

Factors Affecting Carbon Fiber Laser Cutting Effects

Frankly speaking, a laser cutting machine is not a perfect machine. Some professionals have studied that laser cutting may cause a certain degree of thermal damage to the carbon fiber. Therefore, users need to pay attention to the following points and adjust proper parameters to reduce the thermal impact:

- Laser focus position

During laser cutting, the laser beam will be focused on a small spot to melt the cutting seam. The smaller the laser spot diameter, the smaller the heat-affected zone.

- Laser cutting speed

Generally speaking, faster laser cutting speed leads to a smaller heat-affected zone and better cutting quality. Therefore, it is necessary to adjust appropriate laser cutting speed to reduce the thermal influence and ensure the cutting quality.

- Laser cutting power

When the laser cutting power increases, the carbon fiber cutting efficiency is faster and the cutting quality is good. But the laser cutting power can not be too large. Excessive power will increase the heat-affected zone and the cutting slit. Users need to adjust the appropriate laser power for better cutting quality.

- Gas pressure

The gas pressure affects laser cutting quality to a certain extent. During laser cutting, the high-speed airflow quickly blows out the molten material and forms a cutting slit. However, if the gas pressure is too high, the blow-off capability will decrease. If the gas pressure is too small, it will cause an uneven cutting slit. Therefore, the gas pressure must be moderate to achieve a good cutting quality.

In conclusion, users need to pay attention to the above factors to reduce the thermal impact on the carbon fiber material. We suggest you conduct multiple tests, adjust laser power, cutting speed and other parameters to find the most suitable setting.

Summary

Carbon fiber laser cutting has broad development prospects in aerospace, automobile, sports, medical and other industries. There are also many laser cut carbon fiber goods like carbon fiber money clips, carbon fiber signs, carbon fiber clothes which are very popular in our daily life. Carbon fiber laser cutting makes the carbon fiber easier to be cut. Co2 laser cutter can realize efficient and precise cutting and there is no abrasion. However, users need to adjust the parameters of the laser cutting machine to obtain the best cutting effect. DXTECH has rich experience in the manufacturing of high-end laser cutting machines. If you need to find a laser cutting machine to meet your carbon fiber processing needs, please feel free to contact us. We will do our best to provide you with the most suitable carbon fiber laser cutting machine.