Brass is a non-ferrous metal alloy material that is generally made of copper, zinc and other trace metals. This material has good abrasion resistance and a shiny surface. It has wide applications in many industries. We can see brass gaskets, brass valves, brass water pipes, brass company signs, brass screens and other brass goods in our daily life. How to cut brass with high efficiency and precision is an essential question for brass processing companies. Laser technology is one of the most popular brass processing technologies in the current world. Brass laser cutting has high efficiency and high precision, which can meet a variety of brass processing needs. Therefore, it is necessary for brass processing companies to understand brass laser cutting technology and apply it to the production plan.

Why Using Laser for Brass Cutting?

With the development of metal processing industries, there are multiple cutting technologies available for metal cutting, such as flame cutting, plasma cutting and laser cutting, etc. However, some of these are not applicable for brass metal cutting. Flame cutting is only suitable to process carbon steel. Plasma cutting can cut multiple metal materials while its cutting performance for thin metal plates is worse than laser. Therefore, laser cutting is the most suitable way to process brass sheets and brass pipes. And laser cutting can deal with both thin brass sheets and thick brass plates.

Laser cutting has many advantages over other metal cutting methods. It can handle multiple metal materials including brass, aluminum, stainless steel, carbon steel, galvanized steel, etc. And large laser power can deal with thick metal plates with high precision. Compared with flame cutting and plasma cutting, laser cutting has better processing effects and broader applicability.

How to Cut Brass with Laser?

This video shows how a DXTECH fiber laser cutting machine cuts brass plates and makes beautiful brass items. Fiber laser cutting machine is suitable to process brass, aluminum, stainless steel, carbon steel and many other metals. As you can see from the video, the fiber laser cutting machine cuts brass plates very quickly and precisely. And the cutting slit is narrow and smooth. Brass laser cutting is non-contact cutting, so the brass material keeps a smooth surface and can be used for assembly directly.

Laser cutting can deal with a variety of complex patterns and ensure a fast cutting speed at the same time. What’s more, it doesn’t cause any pollution to the working environment. For brass processing enterprises, laser cutting is the best way for long-term development.

Applications of Brass Laser Cutting

Brass laser cutting technology plays an irreplaceable role in various industries. Laser cut brass metal parts are widely used in the manufacturing of household appliances, electrical equipment and other machinery, such as brass gaskets, brass heat sinks, brass valves, etc. In addition, there are a variety of laser cut brass products that are both practical and beautiful, such as brass lamps, brass necklaces, brass screens, brass advertising signs, brass bookmarks, etc. In the following content, we will introduce the applications and advantages of brass laser cutting in each field.

Brass Laser Cutting Makes Brass Metal Parts

Brass has good corrosion resistance, so people use it to make brass gaskets, brass heat sinks and other brass metal parts. The cutting requirements of brass parts are high precision, smooth edge and fast speed. In addition, the surface of brass parts needs to be smooth and there is no deformation. Brass laser cutting has no cutting force to the brass so there is no deformation on the material. Moreover, brass laser cutting produces a narrow and smooth slit on the brass. And laser cutting is an automatic cutting and doesn’t need much human intervention. It saves processing costs and labor costs for brass processing enterprises. That is why many companies choose laser cutting to make brass metal parts.

Laser cutting has good flexibility and won a broad market in many industries. Its automatic typesetting ensures a higher material utilization ratio and lower processing cost. Laser cutting brass has a good economical effect, it is one of the best choices for brass metal parts companies.

Brass Laser Cutting Makes Brass Lamps

Laser cut brass lamp has a unique golden color and is popular in the interior decoration field. There are many types of laser cut brass lamps, such as brass pendant lamps in the living room, brass downlights on the wall, brass table lamps for the bedroom, etc. The exquisite brass lamps are suitable for Nordic, modern and luxurious decoration styles. Laser cut brass lamps are stable, durable and corrosion-resistant. And laser cut brass lamp shade has longer service life than ordinary lamp shades. What’s more, laser cut lamp is beautiful and adds a unique decorative effect to the home, high-end hotels and art galleries. It presents a beautiful effect under the lighting effect. And different colors of light will also present different decorative effects.

For lamp manufacturers who are pursuing the details of lamps, brass laser cutting can achieve precise processing without any burrs, and the brass surface is as smooth as new. Brass laser cutting can make lamps that have good quality, perfect details, long life, no rust, and a beautiful appearance. These good characteristics bring rapid cost return for lamp manufacturers.

Brass Laser Cutting Makes Brass Decorations

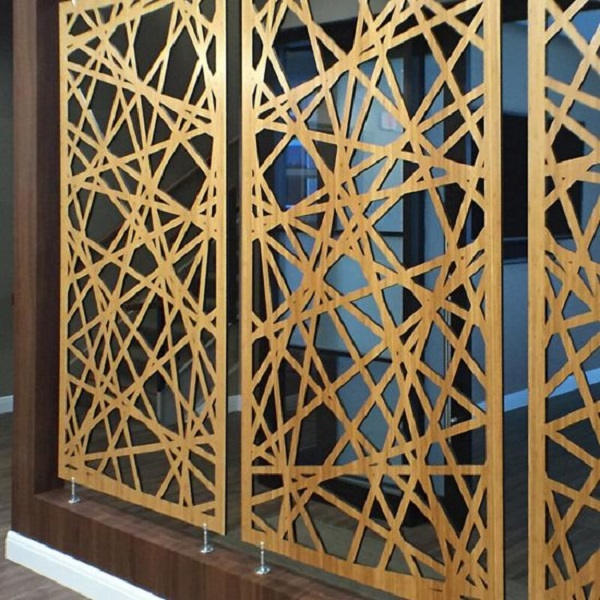

Brass decorations have various applications in many places by virtue of their beautiful color and good durability. Laser cut brass decorations have both decorative effects and good practicalities. Brass laser cutting shows excellent performance in the processing of brass decorations. For example, when laser cutting brass screens, the laser cutting machine efficiently completes the hollow cutting on the brass plates. The products can be sold directly after proper welding and polishing. Laser cut brass screens can well decorate various places, such as the living room, dining room, bedroom, hotels, cafes, etc. The beautiful brass screens divide the space, keep the home in order, and bring a good visual experience for the owners and visitors.

Brass laser cutting can not only handle large-sized brass decorations like brass screens but also perform high-precision processing on small-sized brass decorations. Some examples are brass candle holders for table decoration, brass flower pots, brass pen holders, etc. The brass laser cutter can realize fine processing and free pattern processing. In addition, some high-end customers have unique requirements for the designs of brass decorations. And laser cut brass decorations can be customized according to customers’ requirements, and the product can perfectly meet their expectations.

Brass Laser Cutting Makes Brass Jewelries

Brass has beautiful color and shiny surface. It is an excellent alternative to gold. Brass is easy to cut with a laser and has been the first choice for many jewelry manufacturers and jewelry designers. The processing of brass jewelry such as brass earrings and brass necklaces requires unique shapes, smooth arcs, and no burrs. In addition, brass jewelry should be small, delicate, beautiful and generous. Manual cutting or mechanical knife cutting cannot meet these strict requirements. The brass laser cutter processes brass precisely and can make exquisite brass jewelry. Brass laser cutting can handle holes, sharp corners, arcs and other complex jewelry cuts that are difficult to cut by hand. With a laser cutting machine, the jewelry workers can make beautiful cuts on the brass.

Brass laser cutting has good flexibility and can make complex patterns on brass jewelry. For jewelry designers, laser cutting is the best method to realize their designs. What’s more, during the laser cutting process, the cutting head does not directly contact the jewelry surface. As a result, there is no deformation or burrs on the jewelry. And after the laser cutting, the jewelry manufacturers can polish and assemble the brass jewelry directly.

Brass Laser Cutting Makes Brass Signs

Laser cut brass metal signs are very popular in various companies such as restaurants, financial companies, banks, law firms and so on. Beautiful brass signs can reflect the company’s professionalism and strength. And the beautiful brass signs also enhance the trust of the company’s visitors. For company sign suppliers, laser cut brass signs have broad application prospects and great market demand. Laser cutting brass company signs is very fast and easy to obtain for beginners. It can save labor costs and processing costs for the sign suppliers. Laser cut brass signs are easy to maintain and durable. The surface of the brass sign is bright and novel. And laser cut signs can be installed on acrylic panels or with a gasket to show a floating effect.

In addition, we often see brass house signs sold at affordable prices in household goods stores. These brass house signs are more durable and more beautiful than ordinary house signs. Laser cutting is a convenient way to make brass house signs. And there are no restrictions on the processing patterns. In addition, there will be no brass chips left on the sign surface.

Brass Laser Cutting Makes Brass Bookmarks

Thin brass plates are ideal materials to make exquisite metal bookmarks. Laser cut brass bookmark has a shiny surface and exquisite texture. A beautiful and creative laser cut brass metal bookmark can be a meaningful gift for friends and lovers. The laser cutting machine has a wide processing range. A low-power fiber laser cutting machine or a CO2 laser cutting machine can both process thin brass plates and make exquisite brass bookmarks. Laser cut brass bookmarks have good quality and are worthy of collection. In addition, from the perspective of details and design, the use of laser processing brass bookmarks can minimize the waste of materials, achieve smooth cutting edges, and do not require subsequent processing.

How to Choose a Brass Laser Cutter?

After knowing the applications of brass laser cutting technology, now it’s time to know how to purchase a suitable brass laser cutter.

The basic principle of brass laser cutting is the same as that of steel laser cutting. However, brass is more reflective than steel, so it responds differently to the irradiation of the laser beam. The laser manufacturers found that using a shorter wavelength beam can reduce reflectivity and perform a more precise cutting. In addition, using nitrogen as auxiliary gas can achieve better cutting accuracy and improve cutting efficiency.

Different users have different processing requirements on the brass laser cutter. And different types of brass materials require different laser powers. Therefore, when buying a brass laser cutter, you need to choose a suitable one per your processing needs. And you need to know the processing range and the minimum cutting thickness of a brass laser cutter. The manufacturers will also provide some recommendations according to your needs and provide suitable cutting parameters. In addition, visiting the laser cutting machine factory and testing the cutting effect with your brass samples can help you get an ideal brass laser cutter.

DXTECH Recommends Brass Laser Cutting Machine

Do you want to purchase a brass laser cutting machine and make exquisite brass products? If yes, what kind of brass laser cutter is a good choice for you? In the following part, we recommended three cost-effective brass laser cutting machines that have good performance when processing brass materials. You can select the suitable one according to your machining scale and requirements.

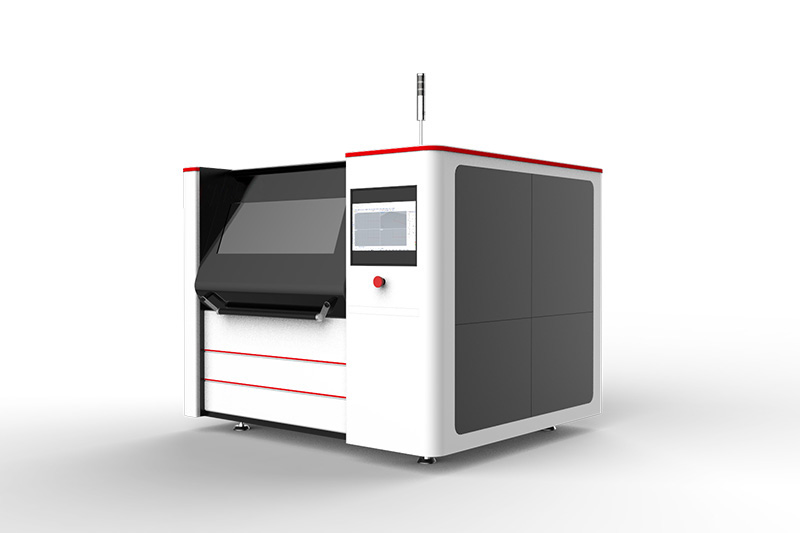

For Small-scale Brass Laser Cutting

This small format fiber laser cutting machine is suitable for small-scale brass laser cutting needs. It adopts a protective cover that ensures the safety of the operator. And this machine has a compact size and high cutting precision. The operation is user-friendly, it is very easy to learn for beginners. If you want to make small brass products, like brass lamps, brass signs, brass metal parts, brass decorations and so on, this small format fiber laser cutting machine is an ideal choice for you. You can click here to know more details.

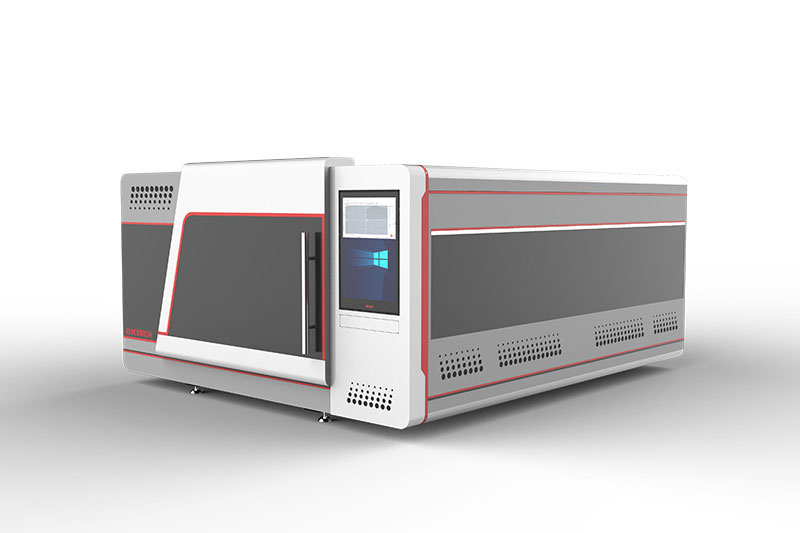

For Middle and Large-scale Brass Laser Cutting

This protective cover fiber laser cutting machine has stronger laser power and can deal with middle and large brass materials. It adopts a protective cover that protects the operator’s safety. This fiber laser cutting machine is suitable for working environments with high environmental protection requirements. The machine is equipped with a high quality laser generator that releases strong cutting power to cut brass. To know more details about this protective cover fiber laser cutting machine, you can click here.

For Brass Metal Laser Cutting and Brass Pipe Laser Cutting

This fiber laser cutting machine is not only a brass sheet cutter but also a brass pipe cutter. It adopts a rotary device that holds brass pipes and conducts the laser cutting with high efficiency and precision. Combined with the brass sheet cutter and brass pipe cutter, this fiber laser cutting machine has broad applications in many industries. And the high-end high quality accessories can ensure the stable operation of the machine. If you want to learn more details about this fiber laser cutting machine, you can click here.