Advantages:

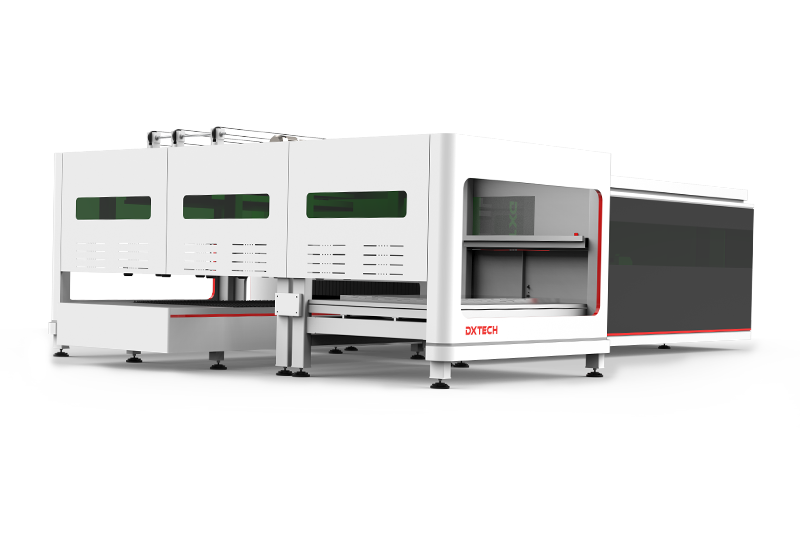

Fast speed

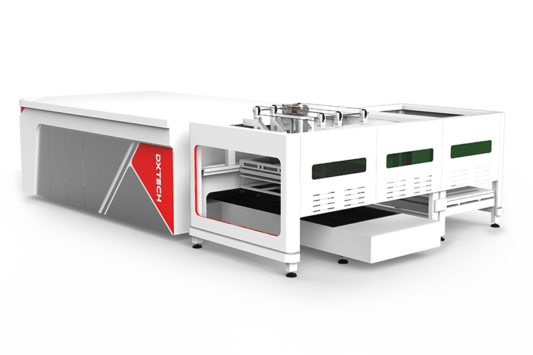

The full automatic loading and unloading laser cutting machine can be loaded quickly, and the continuous loading time is as short as 110 seconds. When it cuts 10mm stainless steel, the speed is at least 10% higher than that of ordinary cutting. While ensuring the cutting quality, the speed is doubled.

Fully automatic

The loading and unloading system is added on the basis of ordinary laser cutting machine, which can realize automatic cutting of pipes in batches without human intervention. It saves time and manpower greatly.

Environmentally friendly & Efficient

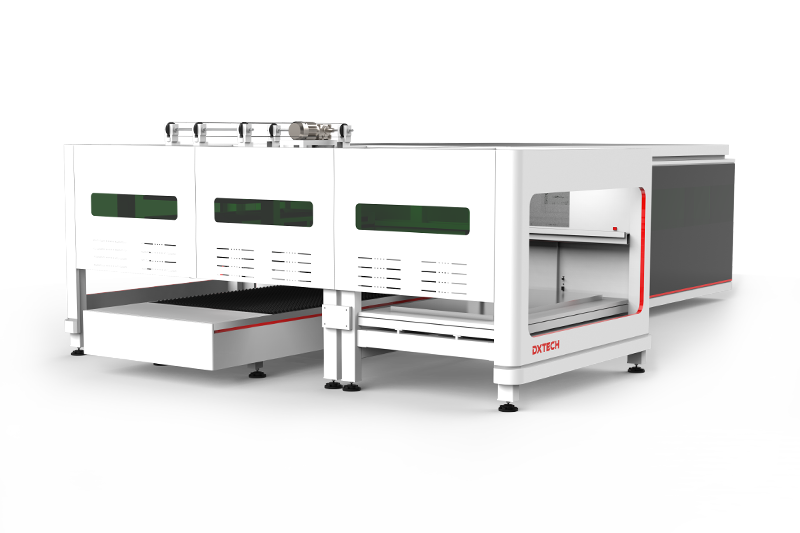

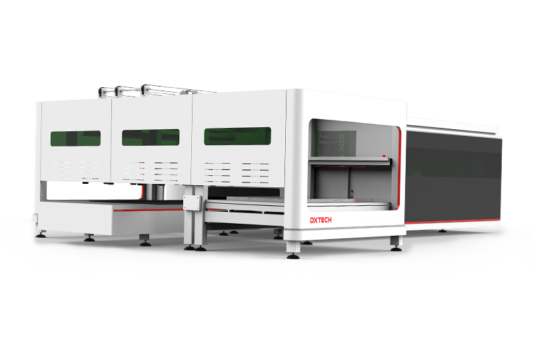

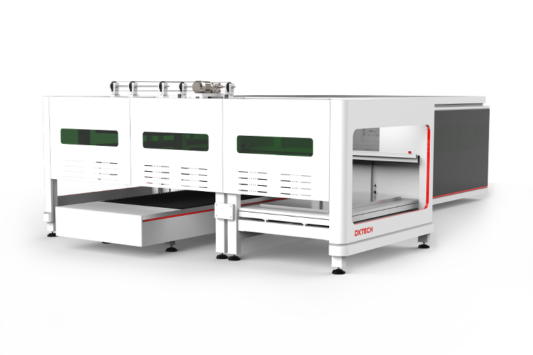

The humanized design of the whole loading and unloading laser cutting machine makes the best use of raw materials. It can improve the cutting efficiency, reduce production costs and realize “0” tailings. And the large envelop can effectively protect against radiation and prevents mechanical damage.

Cost-effective

This automatic loading and unloading machine has the advantages of low cost. Under a certain power, the cutting cost is only 10% of nitrogen cutting, which can create more economic value for customers.

Features:

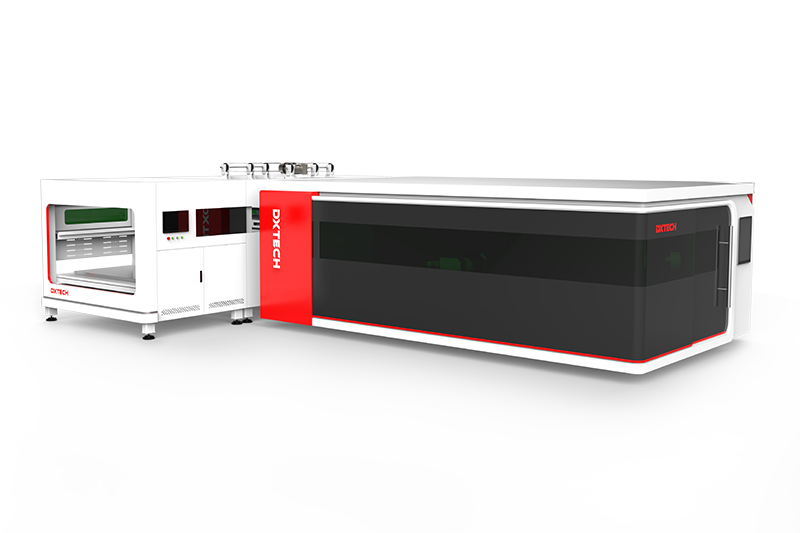

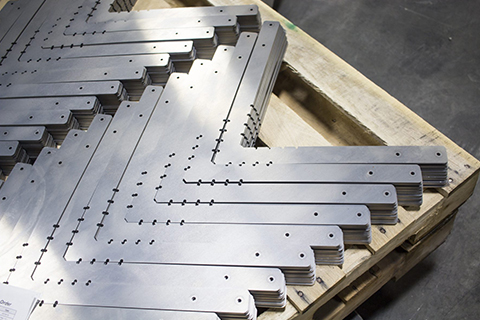

The full automatic loading and unloading laser cutting machine can easily cut a variety of metal tubes with different types and thicknesses. Besides, it can also operate efficiently and stably for a long time. In addition, it can highly identify and detect the height of finished materials in real time. Once the material pallet is full, the machine will send out an intelligent reminder. Because the automatic loading and unloading system has the advantages of strong dynamic performance and high automation integration, its products are widely used in many industries, such as the engineering machinery, electrical cabinet industry, elavator industry, kitchen equipment, machine tools, lighting hardware, advertising signs, auto parts, exhibition equipment, various metal products, sheet metal cutting and processing industries, etc.

DXTECH Service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Components of Fiber Laser Cutting machine

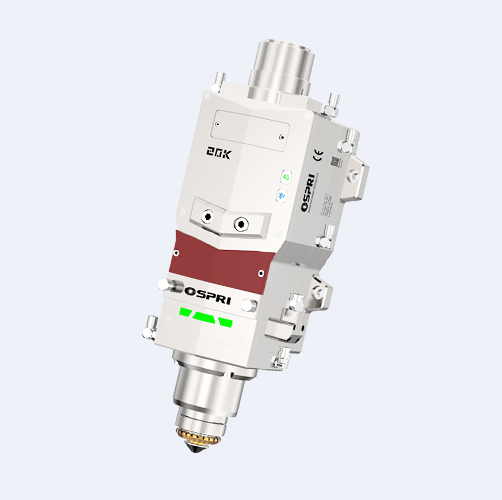

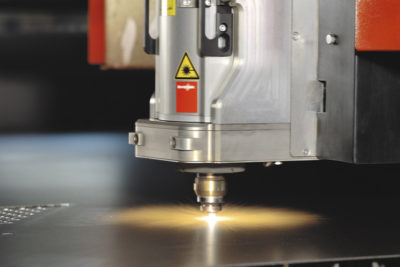

Intelligent focusing laser head

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Aviation aluminum beam

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

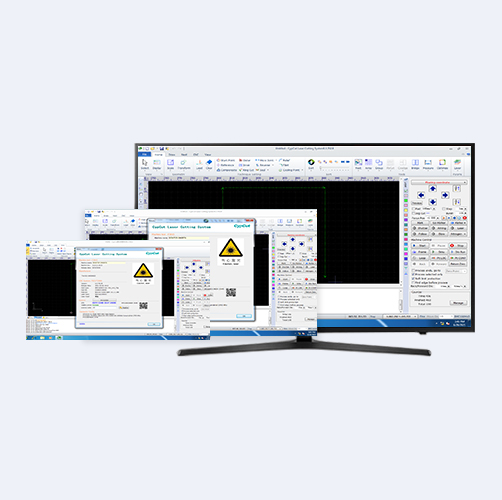

Weihong LS1500/LS3000 Laser Cutting Control System

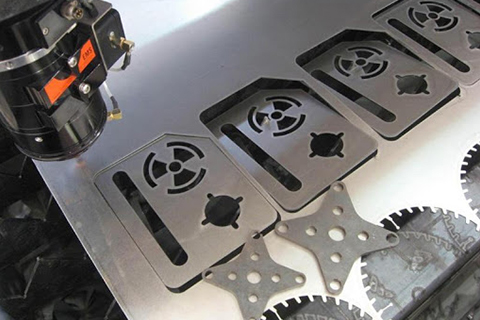

Weihong laser cutting control system is a software for plane laser cutting. It supports AI, DXF, PLT and international standard G codes generated by Mater Cam, Type3, Wentai, etc.

Except common editing and typesetting functions, it has unique processing sequence browsing and powerful material database to load the specification directly. Besides, operators can control the system through wireless handheld box and Ethernet conveniently.

We provide free proofing service. Welcome to consult.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.