As we all know, steel has strong toughness and strength and is an essential material for all walks of life. And laser cut steel has been widely used in sheet metal customization processing, machinery production, advertising, and decoration industries, because of its high precision and convenient processing.

Therefore, the following introduces the best applications of laser cut steel, its processing technology and its advantages.

What industries are laser cut steel used for?

The laser-cut steel can be used in many different industries related to steel processing. For instance, there are elevator manufacturing, medical instruments, and the advertising industries.

Laser cutting metal for machine work

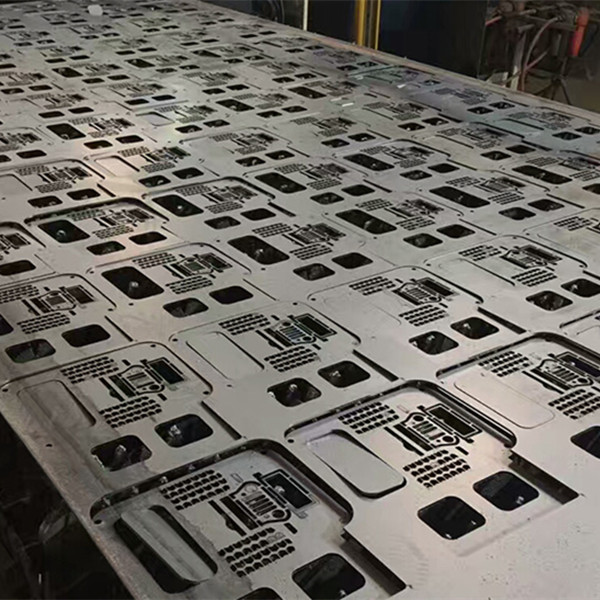

The processing of laser cutting metal sheet meets the requirements of multiple varieties, multiple batches, and small quantities. This kind of CNC metal cutting process can also realize non-standard processing and has high precision.

The laser steel products are updated quickly now. Small batch custom metal cutting production has become the mainstream of sheet metal processing. In the past, the cost of a device shell mold is very expensive. And it takes several months for mold development and production and requires repeated mold repairs, and the accuracy is poor.

While the application of laser cutting metal sheets greatly saves the cost of mold opening and secondary processing. And the production cycle is also shortened, which cannot be achieved by other hardware processing and die stamping.

Laser cutting metal sheet also owns an additional advantage that the cutting edge will produce a shallow hardened layer. And such a layer can improve the wearing resistance of the laser cut steel.

Laser cut steel for elevator manufacturing

Laser cut steel, especially for 3mm laser cut stainless steel, is generally used for elevator manufacturing. In order to ensure the smoothness of the stainless steel plate, the single-side coated stainless steel is basically used. This brings certain difficulties to the traditional processing methods, such as damaging the surface coating of steel.

But the laser steel processing does not have the difficulties. So, what are the advantages of laser cutting steel plates for elevators?

Flexible processing and low cost

The elevators are basically customized products in small batches, and the interior decorations are also very different. There are many types of elevator sheet metal parts. However, traditional processing methods have long mold opening cycles, complex programming, and high requirements for operators.

With the laser cutting machine, laser steel products with various patterns and sizes can be processed. The more important is that it also realizes real custom metal cutting and reduces product development costs. And thus, laser cut stainless steel has been widely used in elevator manufacturing.

Efficient processing and high quality

The speed of cutting steel materials is extremely fast, which improves processing efficiency. In addition, the non-contact processing of laser cutting steel plate avoids deformation during the cutting process.

Furthermore, this kind of CNC metal cutting processing method improves the elevator quality and upgrades the grade of elevator products.

Laser Cut Steel for Kitchenware

The high-end kitchenware products in the market are generally made of laser cut stainless steel sheet and metal panels. Their thickness is mostly less than 3mm. Moreover, there are many laser cut stainless steel sinks, and floor drains are processed by laser cutting machines.

Additionally, kitchen and bathroom products are updated quickly and the market demand is large. Many manufacturers prefer choosing laser cutting metal sheet during the production of kitchenware.

The processing of laser cutting steel plate improves processing speed and efficiency and also completes sheet metal cutting with various shapes. Such a CNC metal cutting process does not need mold or tool changes, shortens the preparation time cycle, and saves many consumables and labor costs.

Moreover, the application of laser steel simplifies the processing technology and process steel kitchenware at a higher level.

The production cycle is short, and the time and cost of mold opening is also reduced. The performance of CNC metal cutting is stable and there are few failures.

There is no stamping or mechanical stress for kitchen and bathroom supplies made of laser cutting steel plate. And the custom metal cutting kitchenware has a smooth surface without burrs, no secondary processing. Furthermore, it can meet the diversified demands of customers.

Laser cut steel for medical instruments

Medical instruments have higher requirements for processing technology and equipment due to their characteristics of accuracy, stability, safety, and purity. More and more medical industry manufacturers are beginning to realize the advantages of laser cut steel plate.

In addition, the laser cut steel for medical use has high precision and high quality cutting edge.

As the laser beam is very thin, the seam of the medical instrument after laser steel processing is very narrow. The small cutting seams guarantee the high cutting precision of laser cutting metal sheets.

In short, the application of laser cut steel has greatly improved the manufacturing quality and sales of medical equipment.

Laser cut steel for decoration engineering industry

Laser cut steel is widely used in the decoration engineering industry. Because of its strong corrosion resistance, high mechanical properties, long-lasting surface layer discoloration, and color change with different lighting angles.

In public places and buildings, the laser cut stainless steel through the custom metal cutting process is used as a decoration material. For example, we often see curtain walls, hall walls, advertising signboard, and front desk screens. Of course, these products are mostly composed of laser cutting steel plate.

Laser cut stainless steel curtain wall

The laser cut stainless steel curtain wall is widely used in office buildings, shopping malls, stations, and many other buildings. The curtain wall of laser cut stainless steel has high strength and stable functions. And in addition, It can prolong the life of the building and enhance the sound insulation effect.

And the curtain wall made of laser cut stainless steel can give people a stronger visual and psychological impact. It relieves the depression caused by the closed space and broadens the field of vision and the perception of space.

Furthermore, the cutting patterns of laser cutting steel plates for the curtain walls can be processed according to customer requirements. The users can cut and drill holes of various shapes on metal materials by using a fiber laser cutting machine.

In short, the laser cut stainless steel can meet customers’ individual pursuit of decoration very well.

Laser cutting metal signs

Laser cut steel can be made into steel letters and signs for advertising and decoration. Stainless steel, titanium, and copper are usually suitable for making laser cutting metal signs.

As the “leading actor” in advertising signs, the laser cutting metal letters have the most direct publicity effect in showing the image of the store and transmitting brand information.

Laser steel letters can also be matched with lights of different colors, making them an eye-catching presence at night. The light shines with the outline of the laser cut steel. And the laser cutting steel brings new vitality to the advertising industry.

The laser cutting metal letters have smooth three-dimensional edges with exquisite appearance. Of course, it is easy to process the custom metal cutting signs by using a fiber laser cutting machine.

Laser cut steel for Gifts & Crafts Processing

In the period when laser cutting technology was not used, the quality of handicrafts was not so good. The accuracy of the art craft products was not so high, and the processing speed was not fast.

However, the application of laser steel processing can realize the strict requirements of art crafts that traditional processing cannot meet. The craft works after laser processing are so equisite and delicate, and let customers fondle admiringly.

The crafts through the custom metal cutting of laser machine are extremely fine. In the numerical control laser setting, the laser steel accuracy is often accurate to a few tenths of a millimeter. Another point is the production of many handicrafts with different materials cannot be done manually. But using the laser machine can cut and engrave the highly difficult crafts easily.

The holiday is approaching, let’s make a laser cut stainless steel necklace or crafts to send families and friends.

How laser cut steel is processed?

The laser cut steel is made by using the fiber laser cutting machine, which belongs to the CNC metal cutting technology. Fiber laser cutting machine is to use fiber laser to generate laser to cut steel and other metal materials mainly. Its high photoelectric conversion rate can reach twice that of carbon dioxide. And it has advantages when processing laser cutting metal sheets. The reason is the light emitted by the fiber laser has a wavelength of 1070 nanometers. Therefore, the absorption rate is higher.

Through the optical path system, the fiber laser emitted from the laser generator is focused to be a high-density laser beam to irradiate on steel. And then the laser heat is absorbed by the steel material, and the temperature of steel rises sharply. After reaching the melting point, the steel begins to melt and vaporize.

And then the melted or gasified steel material is blown away from the cutting seam with high pressure gas.

And the laser cutting machine cut through the steel material and form a very small hole. Along with the movement of the laser head, numerous small holes appear and connect to be the outline of cutting. In this way, the laser cut steel is produced.

Due to the high concentration of laser energy, only a small amount of heat is transferred to other parts of steel. This results in very little or no deformation. The complex shape can be cut very accurately by using laser, and the laser steel does not need further processing.

And the followings two fiber laser cutting machines are very suitable for the processing of laser cut steel products.

Advantages of the processing of laser cut steel by DXTECH fiber laser machine

・High cost performance

The laser cut steel has good cutting quality, small deformation, smooth and beautiful appearance. Moreover, the processing of laser cutting metal sheets shows the features of fast cutting speed, high efficiency, low cost, safe operation, and stable performance.

・Fast and convenient processing

The CNC metal cutting process is realized by using professional laser steel processing software. Laser steel processing does not need to be manually operated frequently. As long as the drawing is input into the system, the laser machine directly controls the input data and output the cost through the computer.

You can design various graphics or texts for instant and flexible processing. The operation of processing laser cut steel is really custom metal cutting.

・Delicate cutting effect

Laser beam of the CNC metal cutting machine is easy to realize time or space splitting, and it can process multiple beams simultaneously or multi-station sequential processing.

・Simple and environmentally friendly

Laser cutting steel plates is directly processed by CNC metal cutting laser machine with numerical control technology. The direct control transmission through the computer program greatly reduces the waste of materials. At the same time, it is more environmentally friendly.

Conclusion

In general, the laser cut steel has a wide application range in various industries. And the laser cutting machine for laser cut steel uses advanced fiber lasers. It is highly automated and intelligent and flexibly responds to various production tasks, effectively reducing the labor intensity of the operators.

The CNC metal cutting machine is convenient to use due to its good laser beam, high precision, smooth cut surface, and pollution-free processing. In addition, it is currently applied in many metal processing and decoration engineering industries.

With the increasingly fierce market competition, we believe that the custom metal cutting products by laser machine will play an increasingly important role and create a new high in the steel processing industry.